Detection and cutting system for plastic protective sleeve outside wire harness

A protective sleeve and cutting technology, which is applied in the cutting system, the processing device of the plastic protective sleeve outside the wire harness, and the detection field, can solve the problems of undiscovered patent documents, errors in human judgment, and inclined line drawing, etc. Achieve the effects of improving detection efficiency and accuracy, simple structure, and reducing scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

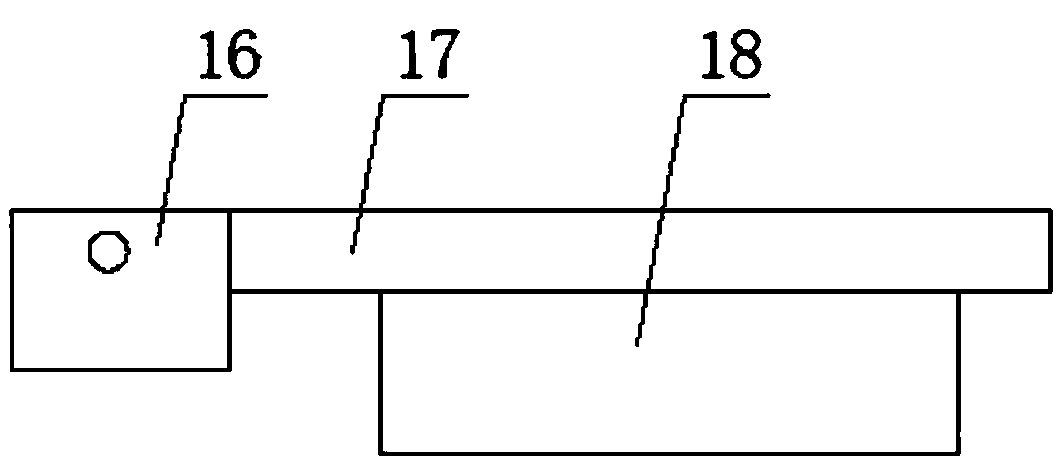

[0022] A detection and cutting system for the outer plastic protective sleeve of the wire harness. A limit block is set on the center line of the front end, a marking mechanism and a detection mechanism are arranged in turn at the rear end of the limit block, and a cutting mechanism is set on the vertical plate of the detection mechanism.

[0023] The limiting block is composed of an end plate 2 and a limiting vertical plate 3 located on both sides of the end plate, and the distance between the two limiting vertical plates is adapted to the outer diameter of the plastic protective sleeve 7 .

[0024] The detection mechanism is composed of an installation stand 8, a front infrared sensor 12, a rear infrared sensor 11, a PLC and an alarm 4. The installation stand is relatively arranged along the width direction of the detection base plate. The front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com