Heat exchanger assembly capable of automatically controlling heating power of left tube box and right tube box

一种换热管、左管箱的技术,应用在浸没式换热器的换热组件领域,能够解决换热效率低、换热效率不高等问题,达到提高换热效率、操作方便、优化最佳关系的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

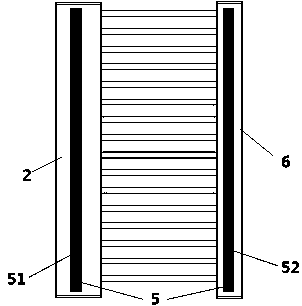

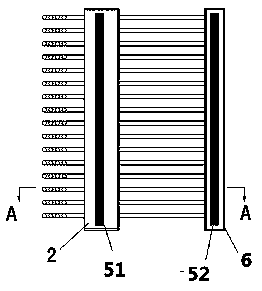

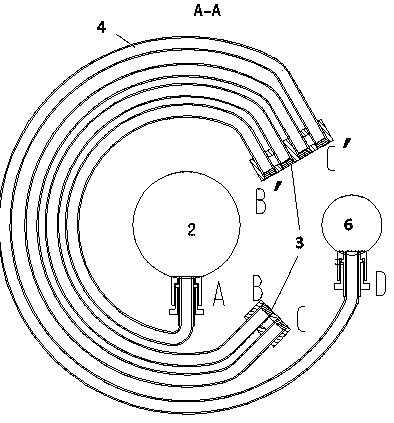

[0037] Figure 1-2 Schematic cutaway diagram showing submerged heat exchange components, such as figure 1 As shown, a submerged heat exchanger assembly includes a left tube box 2, a right tube box 6 and heat exchange tubes, the heat exchange tubes communicate with the left tube box 2 and the right tube box 6, and the electric heating device 5 is arranged on the left The tube box 2 and / or the right tube box 6; the left tube box 2, the right tube box 6 and the heat exchange tubes are filled with heating fluid, and the heating fluid is closed and flows in the left tube box 2, the right tube box 6 and the heat exchange tubes.

[0038] The electric heating device 5 is used for heating the internal fluid of the heat exchange assembly, and then the heated fluid is used to heat the fluid outside the heat exchange assembly.

[0039] Preferably, the electric heating device 5 is arranged in the left tube box 2 or the right tube box 6 .

[0040] Preferably, the heat exchange tubes are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com