A Design Method of Dynamic Bearing Applied to the Crankshaft of Reciprocating Compressor

A compressor crankshaft and design method technology, applied in crankshaft bearings, design optimization/simulation, special data processing applications, etc., can solve problems such as failure to meet bearing safety requirements, and achieve high safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention will be described in further detail below in conjunction with the accompanying drawings:

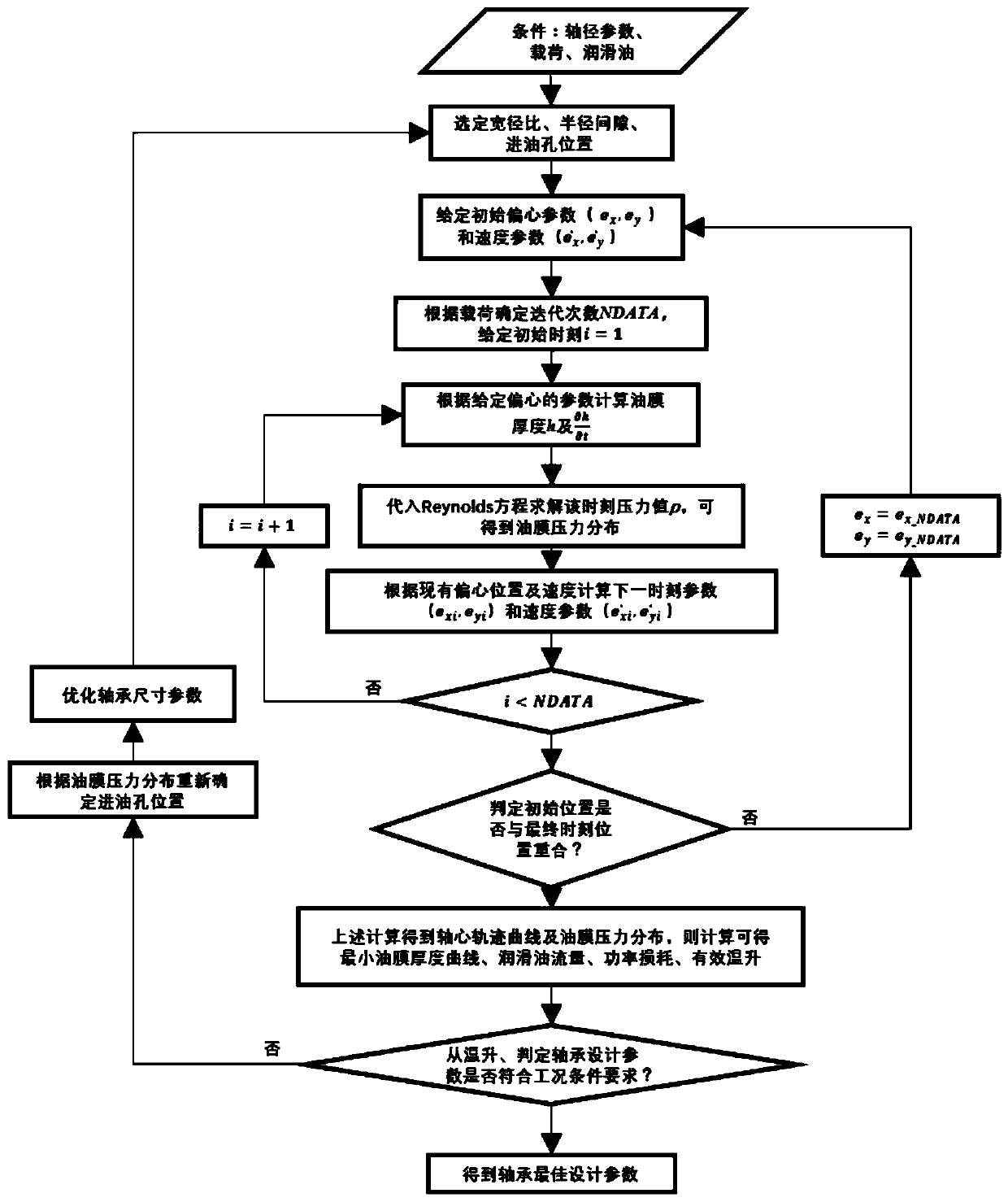

[0075] Such as figure 1 As shown, for the dynamic bearing design process, a dynamic bearing design method applied to the crankshaft of a reciprocating compressor provided by the present invention includes the following steps:

[0076] 1. Determine the width-to-diameter ratio B / D (where B is the width of the bearing and D is the diameter of the bearing) according to the bearing working conditions. For dynamic load bearings, it is preferably 0.3 to 0.8. For bearings with a complete circumferential groove, the preferred range is usually selected The upper limit (B / D=0.8), for bearings without circumferential grooves and oil inlet holes, the lower limit (B / D=0.3);

[0077] 2. Determine the minimum bearing radius clearance with reference to the journal diameter. The maximum bearing radius clearance is 1.5 times the minimum:

[0078] C dmin =0.00075D (1)

[0079] C dmax ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com