While-drilling measuring instrument self-locking device and method

A self-locking device and measurement-while-drilling technology, used in earth-moving drilling, wellbore/well components, etc., can solve the problems of increasing the labor intensity of construction personnel, short service life of check valves, and increasing downhole risks. Avoid key-off accidents, protect instruments, and facilitate successful key-setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

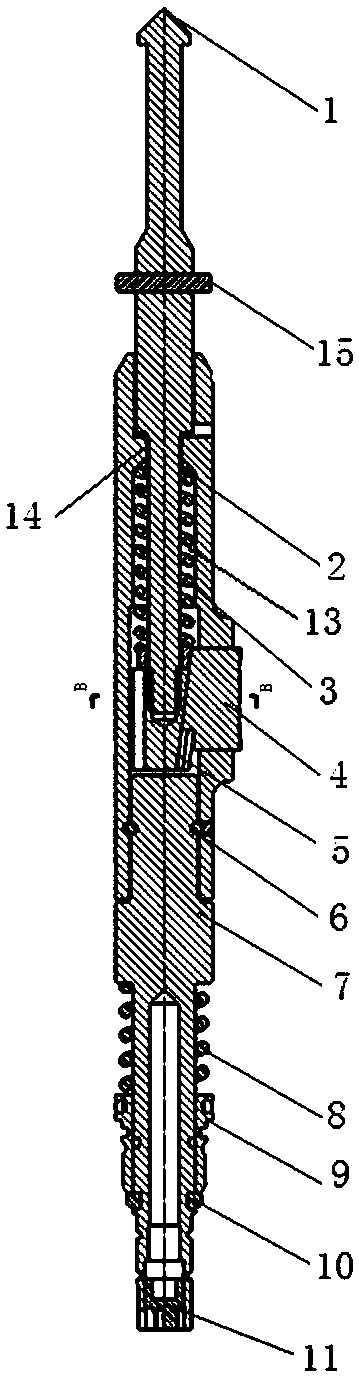

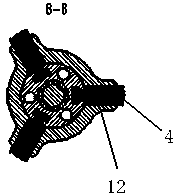

[0027] The present invention includes a self-locking mechanism and an instrument joint, and an instrument joint is provided at the bottom of the self-locking mechanism. 1 is provided with an outer cylinder 2, and the outer cylinder 2 is evenly distributed with three slip grooves 12 in the circumferential direction, and the slips 4 are placed in the slip grooves 12. The inside of the outer cylinder 2 is provided with a bevel body 5, and the bevel body 5 is connected by threads. At the bottom of the fishing head 1, the upper part of the inclined plane body 5 is connected with the lower part of the slips 4, the upper end of the inclined plane body 5 is provided with a locking spring 3, and the lower part of the outer cylinder 2 is provided with an instrument connector, between the inclined plane body 5 and the instrument joint There is a gap between them, the bevel body 5 moves up and down through the locking spring 3, the outer cylinder 2 and the instrument joint are connected by...

Embodiment 2

[0037] The difference from Example 1 is that the outer surface of the slip 4 is provided with gripping teeth 17, which are an alloy layer with extremely high hardness, and the gripping teeth on the surface of the slips eat into the inner wall of the drill tool and are pressed against the inner wall of the drill collar. The formation of locking can avoid the occurrence of key-off accidents of the main body of the measuring instrument and the accident of the instrument falling into the well due to the fracture between the directional joint and the non-magnetic drill collar.

[0038] The instrument joint is connected with the main body of the measuring instrument through the cruise ship 9, and the semicircular clamping flap 10 is stuck to prevent the instrument joint from coming out of the main body of the measuring instrument. The three slips 4 of the cloth protrude outwards and press against the inner wall of the drilling tool. The gripping teeth 17 on the surface of the slips 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com