Steel pipe grouting connector and grouted steel pipe connecting method

A technology for grouting steel pipes and connection methods, which is applied in the field of steel pipe grouting connectors and grouting steel pipe connections, achieving the effects of simple and reliable installation, obvious economic benefits, and reduced construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

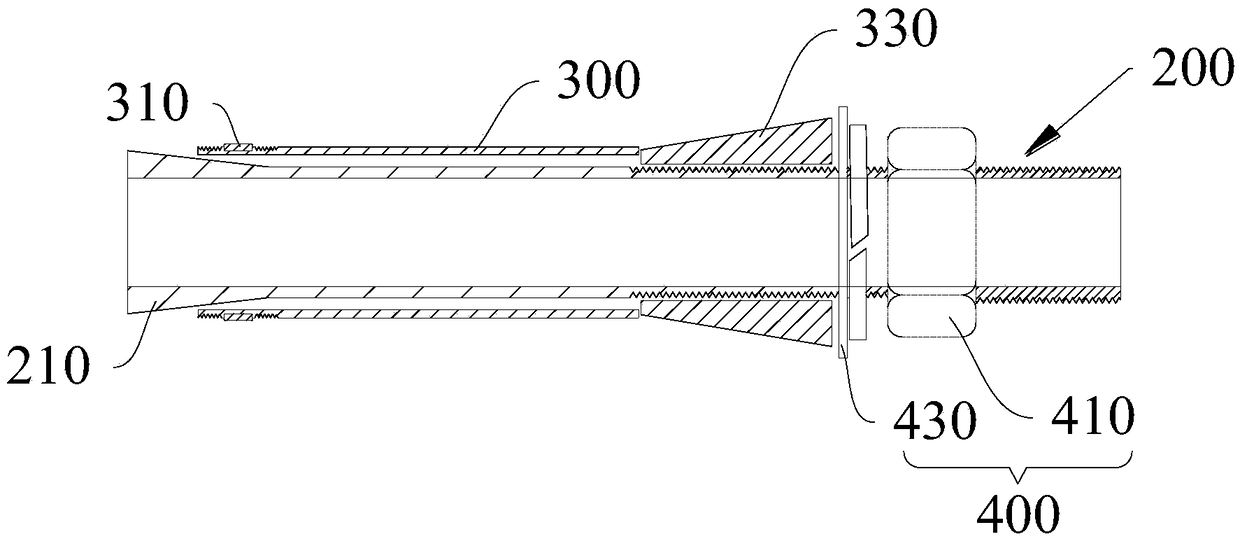

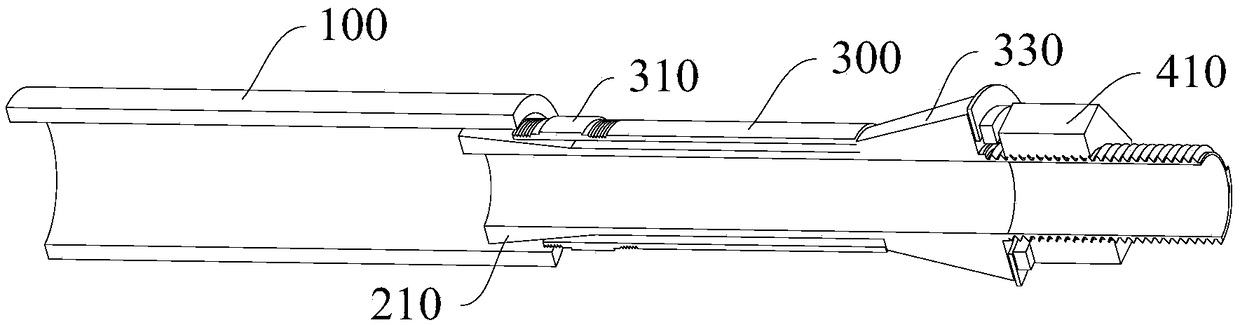

[0036] This embodiment provides a steel pipe grouting connector, please refer to figure 1 , this steel pipe grouting connector includes a grouting steel pipe 100, an expansion head pipe 200, a sleeve 300 and a sliding positioning member 400;

[0037] The sleeve 300 is sleeved on the outside of the expander tube 200, the sleeve 300 is slidingly connected with the expander tube 200, the expander tube 200 is provided with a flaring 210 on the outside of one end, and the other end is provided with a sliding positioning member for abutting with the sleeve 300 400, the sliding positioning member 400 is slidingly connected with the expanding head tube 200;

[0038] The inner wall of one end of the grouting steel pipe 100 has a rough surface matching the sealing ring 310 , and the end of the sleeve 300 away from the sliding positioning member 400 is provided with a sealing ring 310 for sealing connection with the rough surface of the inner wall of the grouting steel pipe 100 .

[003...

Embodiment 2

[0048] This embodiment provides a method for connecting grouted steel pipes 100, please refer to figure 1 , this grouting steel pipe 100 connection method uses the steel pipe grouting connector provided in Embodiment 1, including the following steps:

[0049] Use the eccentric roughening device 700 to grind and roughen the inner wall of the inlet end of the grouting steel pipe 100 to form a roughening section; wherein, the eccentric roughening device 700 can be driven by an on-site pneumatic rock drill;

[0050] Extend the end of the expander tube 200 with the flaring 210 and the end of the casing 300 with the sealing ring 310 into the roughening section of the grouting steel pipe 100;

[0051] The sliding positioning member 400 squeezes the sleeve 300, so that the flaring 210 expands one end of the sleeve 300 where the sealing ring 310 is disposed;

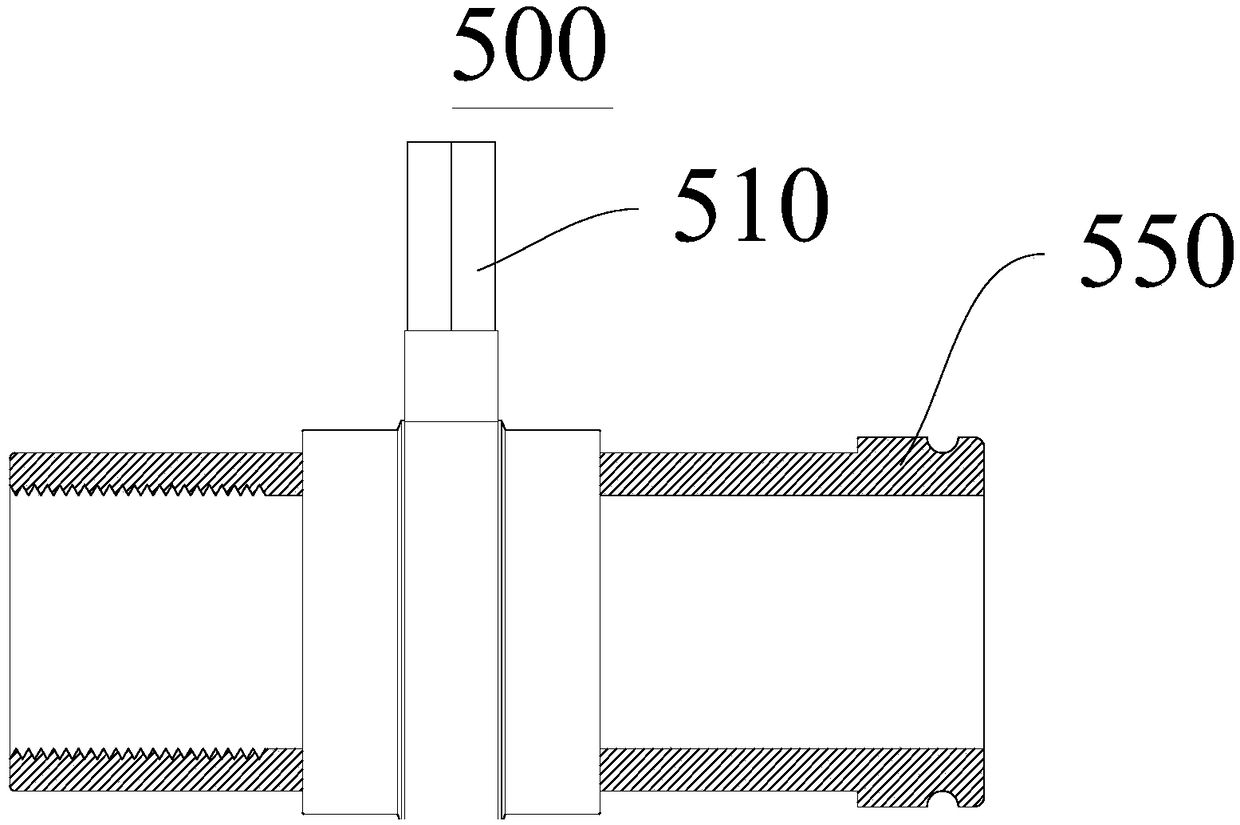

[0052] The end of the expander tube 200 away from the flaring 210 is connected to the slurry stop valve 500;

[0053] A quick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com