Finishing equipment for cotton thread

A cotton thread and equipment technology, applied in the field of cotton thread moistening equipment, can solve the problems of waste of thread moistening liquid, etc., and achieve the effects of wide application range, improved recovery rate, and improved smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following is further described in detail through specific implementation methods:

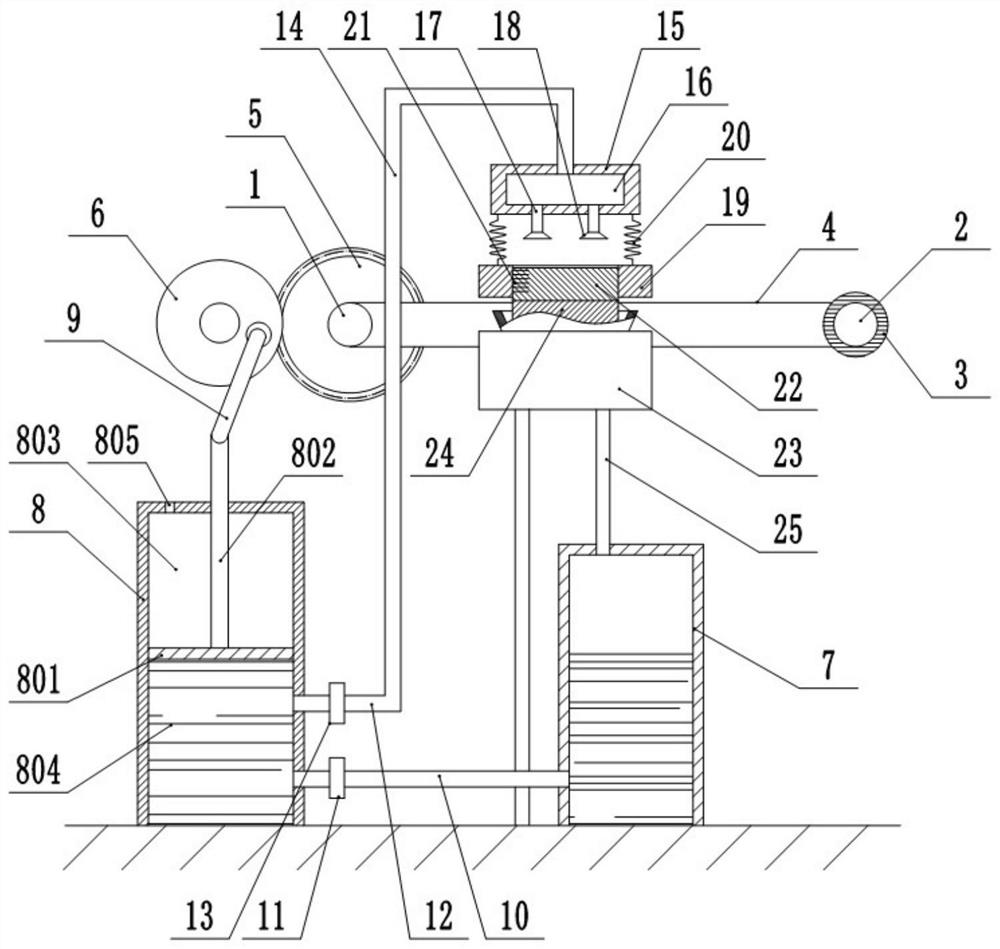

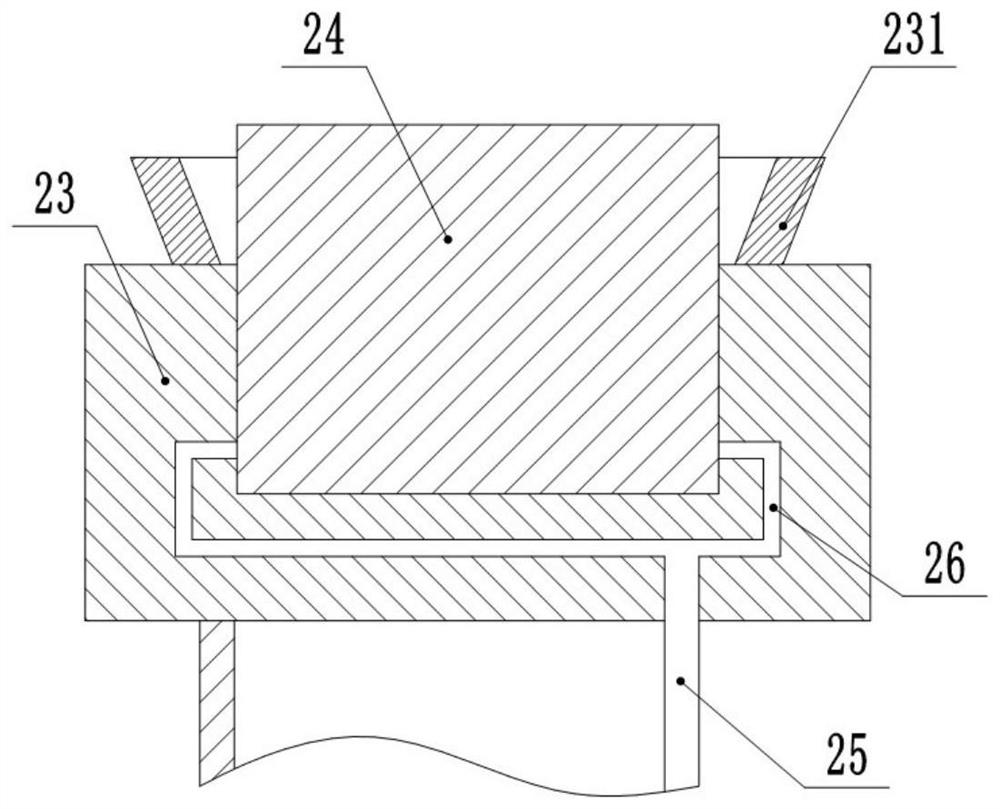

[0020] The reference signs in the drawings of the description include: take-up roller 1, pay-off roller 2, cotton thread reel 3, transmission belt 4, first gear 5, disc 6, box body 7, cylinder body 8, piston 801, piston rod 802 , upper chamber 803, lower chamber 804, air vent 805, connecting rod 9, liquid inlet pipe 10, first one-way valve 11, liquid outlet pipe 12, second one-way valve 13, U-shaped pipe 14, horizontal plate 15. Cavity 16, spray pipe 17, nozzle 18, placement plate 19, spring 20, needle 21, first sponge layer 22, fixed block 23, baffle plate 231, second sponge layer 24, recovery pipe 25, through cavity 26 .

[0021] This embodiment is basically as figure 1 As shown, the cotton thread moistening equipment includes a frame on which a motor is fixedly installed. Line roll 2, the cotton thread volume 3 that is to be moistened is wound on the pay-off roll 2, and the dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com