Blended yarn impurity removal and conveying mechanism

A conveying mechanism and technology of blended yarns, which are applied in textile and papermaking, fiber processing, fiber cleaning, etc., can solve the problem of combing and removing impurities in blended yarns, yarn breakage of blended yarns, short fibers and impurities in blended yarns Difficulty and other problems, to achieve the effect of reasonable structural design, ensuring efficiency and quality, and ensuring wide width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further describe the present invention, a specific implementation of a blended yarn impurity removal transmission mechanism will be further described below in conjunction with the accompanying drawings. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

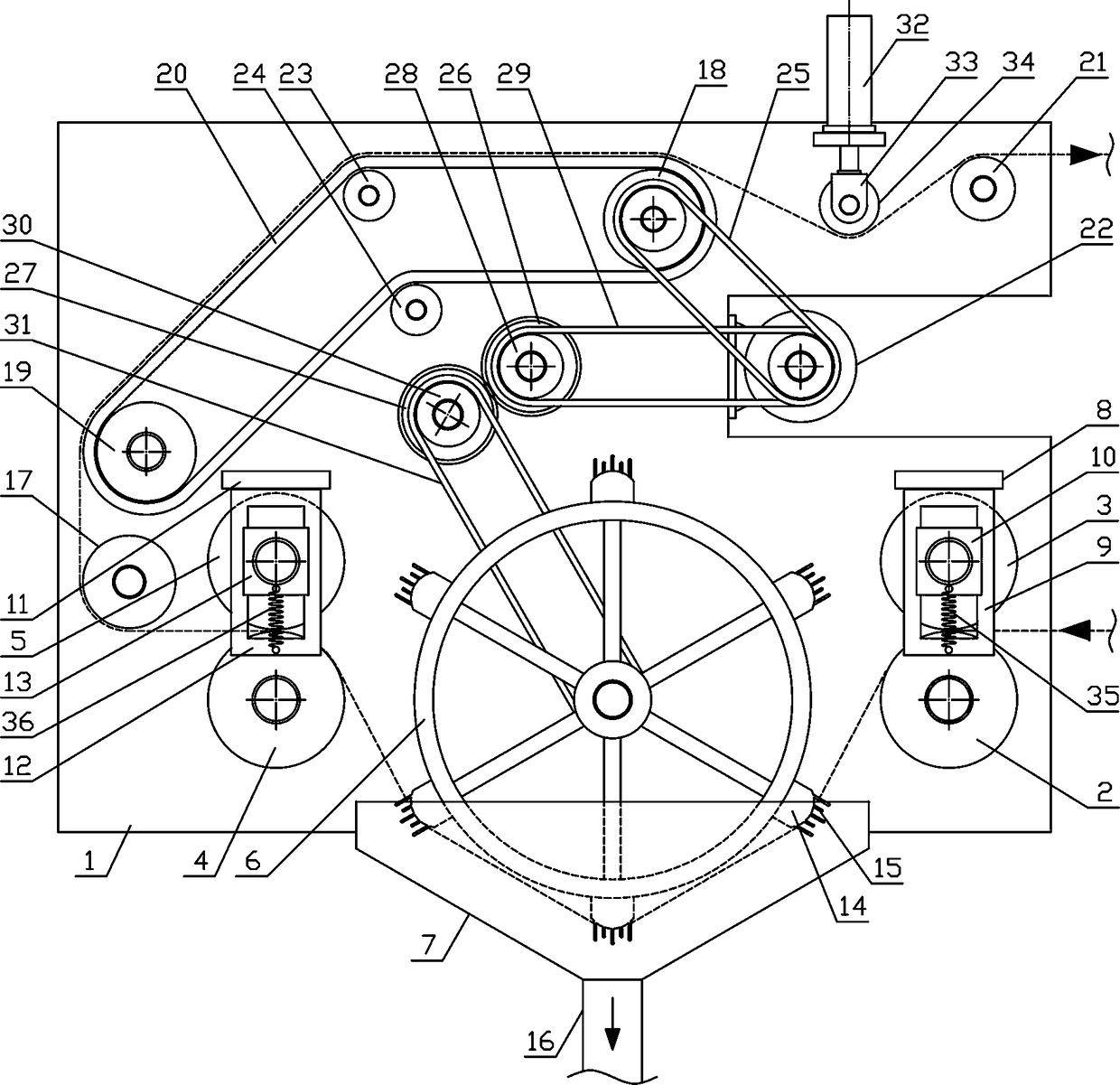

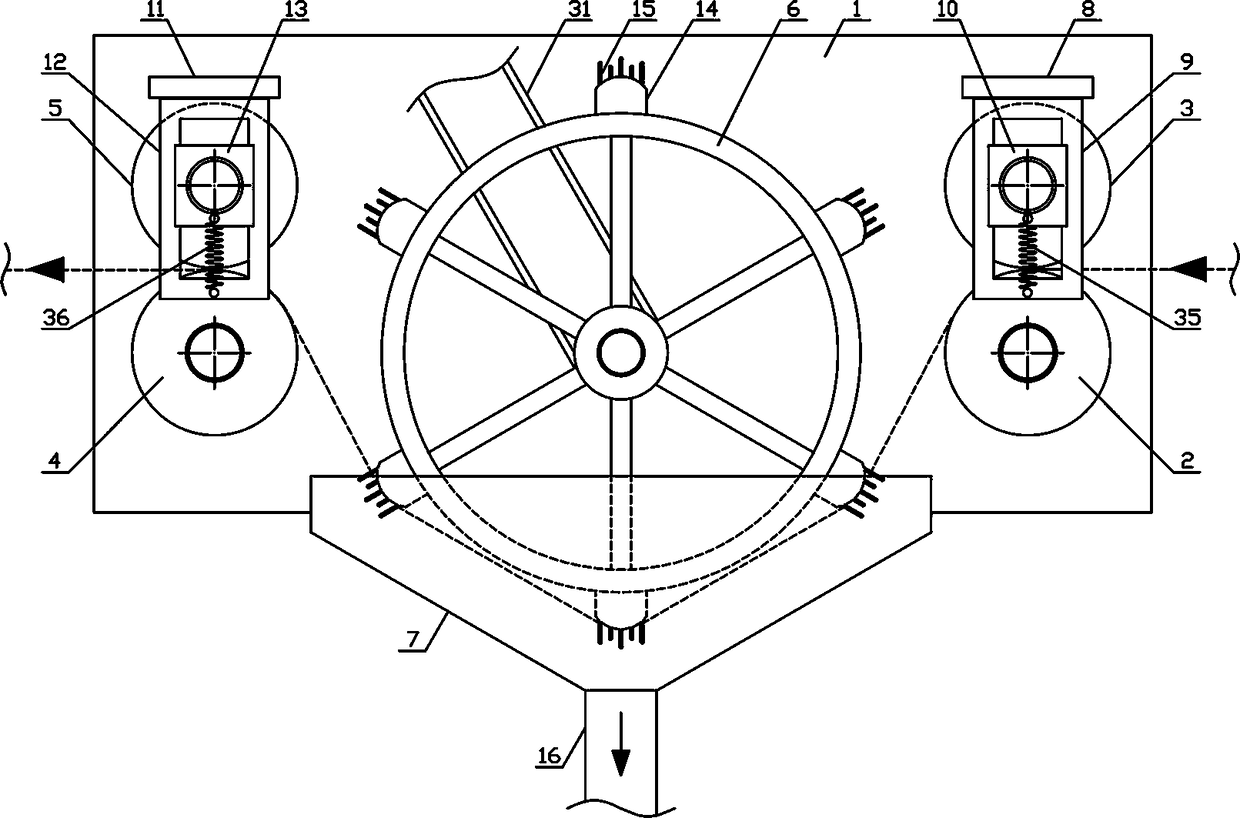

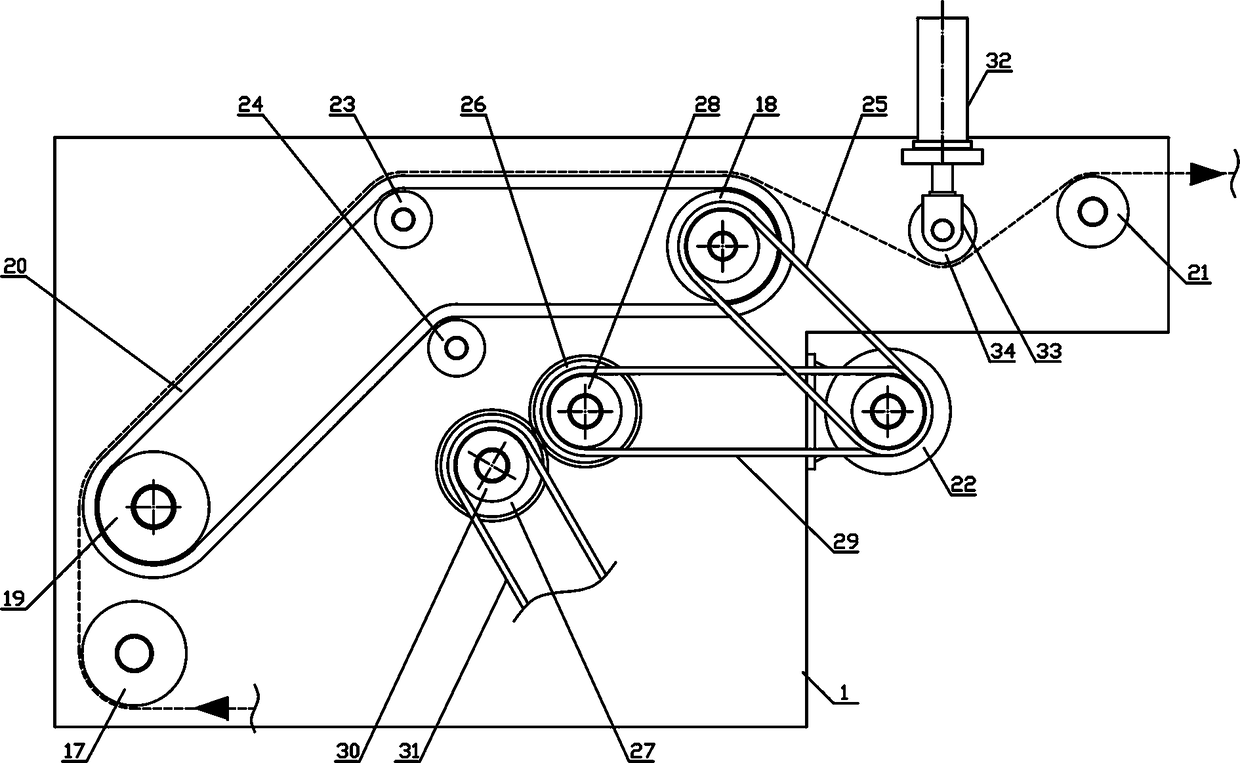

[0015] Such as figure 1 As shown, a blended yarn removal transmission mechanism of the present invention includes a fixed bracket 1, a removal mechanism and a yarn pulling mechanism, and the yarn pulling mechanism and the removal mechanism are fixed horizontally on one side of the fixing bracket 1 from top to bottom. Such as figure 2 As shown, the impurity removal mechanism of the present invention comprises yarn feed roller 2, yarn feed roller 3, yarn outlet roller 4, yarn outlet roller 5, impurity removal drum 6 and dust suction wind cover 7, yarn feed roller 2 and the yarn output rotating roller 4 are horizontally connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com