Cool masterbatches, cool fibers, and preparation method and application of cool master batch

A cool-feeling and masterbatch technology, applied in the field of cool-feeling fibers and their preparation, and cooling-feeling masterbatches, can solve problems such as peculiar smell and reduce comfort, and achieve the effect of good cooling feeling and improving poor comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

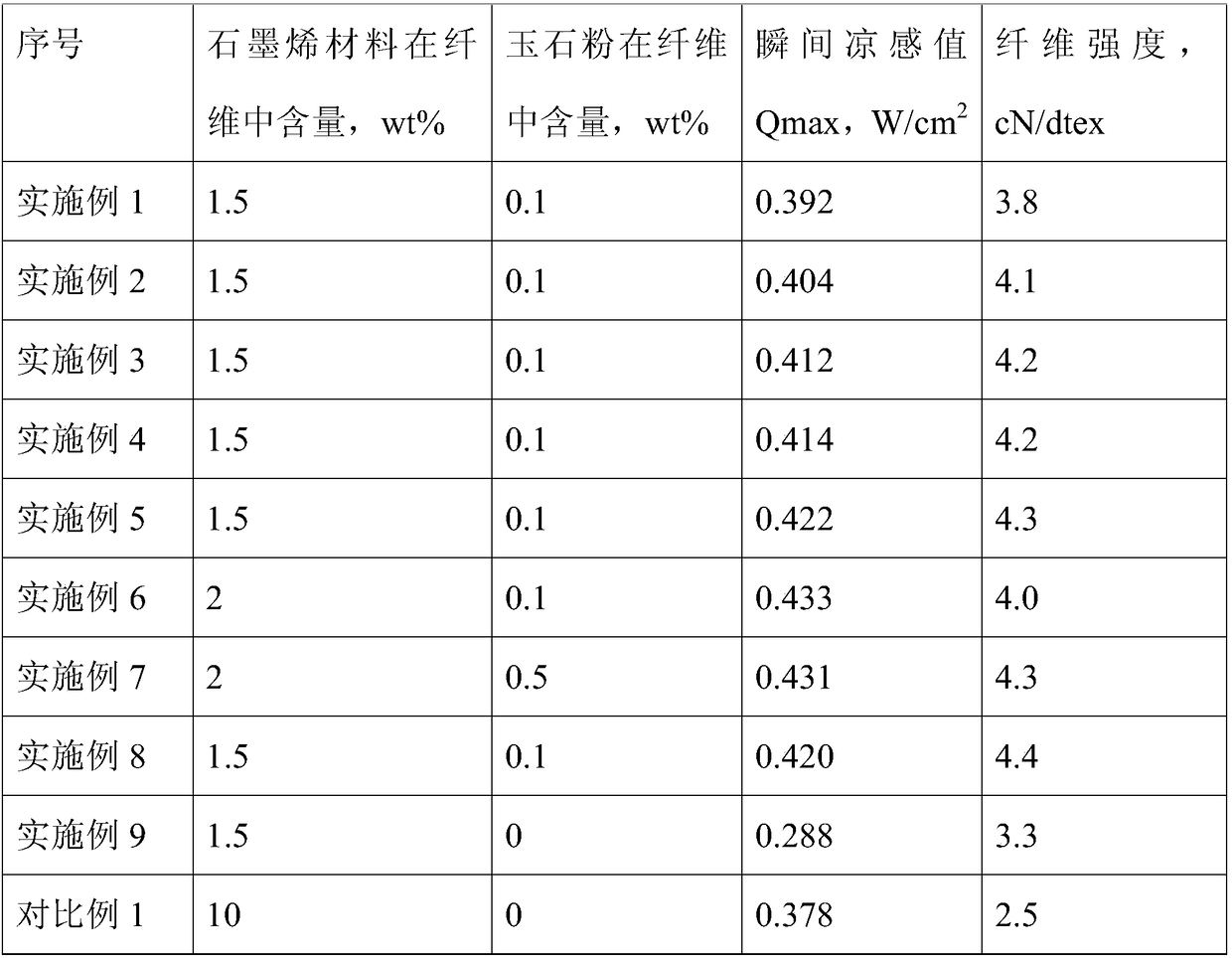

Examples

preparation example 1

[0067] Graphene material with a particle size of D100 (full pass particle size) = 10 μm and jade powder with a particle size of D100 = 10 μm and blank polyester chips are added to the mixer according to the formula and mixed. The mixing temperature is 95 ° C, and then the screw is extruded at 250 ° C. Go out, obtain the 1# cool polyester masterbatch that contains 15wt% jade powder, 1wt% biomass graphene.

preparation example 2

[0069] First mix biomass graphene with a particle size of D100=0.5 μm accounting for 30% of the total amount with blank polyester chips, then add jade powder with a particle size of D100=3 μm for mixing, and then add the remaining 3 μm≤D100≤10 μm Biomass graphene, the mixing temperature is 95°C, and then screw extruded at 250°C to obtain 2# cool polyester masterbatch containing 15wt% jade powder and 1wt% biomass graphene.

preparation example 3

[0071] First mix the biomass graphene with particle size D100=1 μm with 10wt% blank polyester chips, then add 20wt% blank polyester chips to the mixture and continue mixing, then continue to add 50wt% blank polyester chips to the resulting mixture Slice and mix, then add biomass graphene with a particle size of 1μm≤D100≤10μm, then add jade powder with a particle size of D100=3μm for mixing, the mixing temperature is 95°C, and then screw extrude at 250°C to obtain 15wt % jade powder, 1wt% biomass graphene 3# cool polyester masterbatch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com