Organic fertilizer and preparation method thereof

A technology of organic fertilizer and parts by weight, applied in the agricultural field, can solve problems such as unsatisfactory fertilizer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

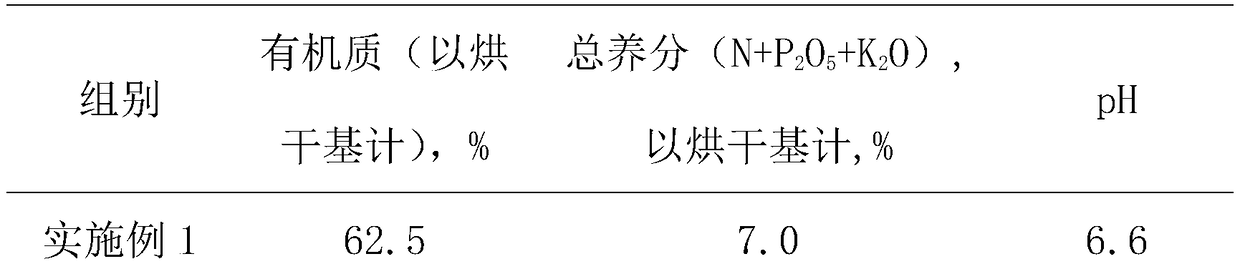

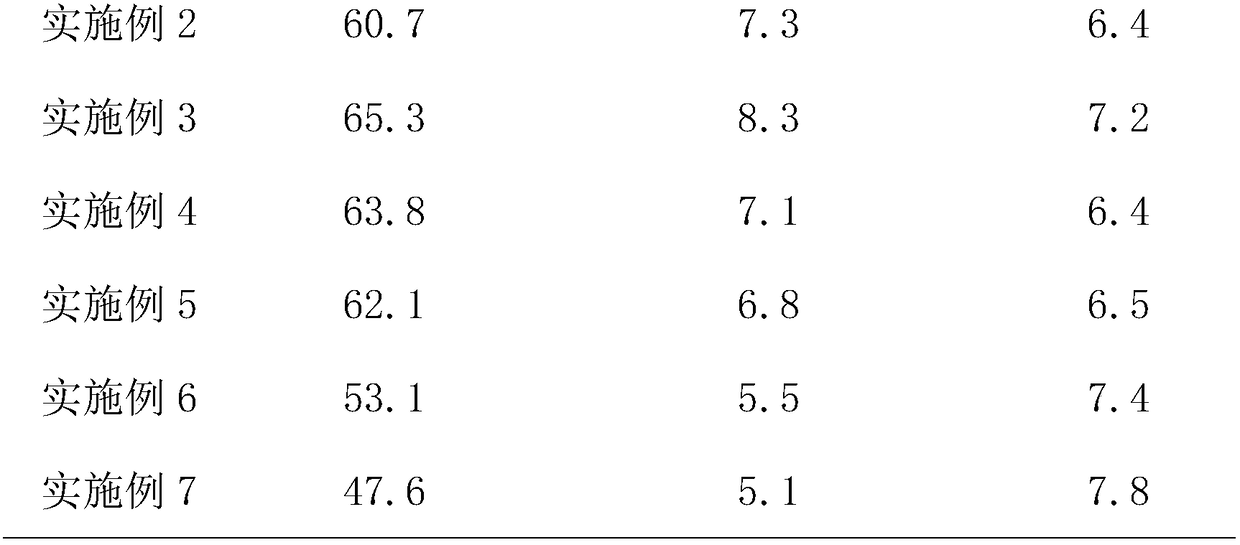

Examples

Embodiment 1

[0025] The present embodiment provides an organic fertilizer, which is mainly made from the following raw materials by weight: 620 parts of oil dregs, 100 parts of sugar residue, 50 parts of sheep dung, 230 parts of cow dung, 60 parts of corn stalk, 100 parts of rice straw and 10 composite bacteria agents.

[0026] The preparation method of this organic fertilizer comprises the following steps:

[0027] S1, take by weight oil dry, sugar residue, sheep dung, cow dung, corn stalk and straw, and be pulverized to 50 meshes;

[0028] S2, take by weighing the compound bacterial agent by weight, it is mixed with pulverized oil dregs, sugar residue, sheep dung, cow dung and straw to obtain fermented material, which is 0.5:1 to the weight ratio of water and fermented material. Add water to the fermented material, mix evenly, pile the fermented material into a fermented pile with a length of 3 meters, a width of 1 meter and a height of 0.5 meters, and ferment for 10 days to obtain a fe...

Embodiment 2

[0034] This embodiment provides an organic fertilizer, which is mainly made from the following raw materials by weight: 200 parts of oil dregs, 380 parts of sugar residue, 140 parts of sheep dung, 80 parts of cow dung, 190 parts of corn stalk, 30 parts of rice straw and 29 pieces of compound bacterial agent.

[0035] The preparation method of this organic fertilizer comprises the following steps:

[0036] S1, take by weight oil dry, sugar residue, sheep dung, cow dung, corn stalk and straw, and be pulverized to 100 meshes;

[0037] S2, take the composite bacterial agent by weight, mix it with pulverized oil dregs, sugar residue, sheep dung, cow dung and straw, obtain fermentation material, be 1:1 to the weight ratio of water and fermentation material Add water to the fermented material, mix it evenly, pile the fermented material into a fermented pile with a length of 5 meters, a width of 0.8 meters and a height of 0.8 meters, and ferment for 5 days to obtain a fermented produ...

Embodiment 3

[0043] This embodiment provides an organic fertilizer, which is mainly made of the following raw materials by weight: 410 parts of oil dregs, 265 parts of sugar residue, 87 parts of sheep dung, 136 parts of cow dung, 108 parts of corn stalk, 66 parts of rice straw and 19 composite bacterial agents.

[0044] The preparation method of this organic fertilizer comprises the following steps:

[0045] S1, take by weight oil dry, sugar residue, sheep dung, cow dung, corn stalk and straw, and be pulverized to 80 meshes;

[0046] S2, take the composite bacterial agent by weight, mix it with pulverized oil dregs, sugar residue, sheep dung, cow dung and straw, obtain fermentation material, be 1:1 to the weight ratio of water and fermentation material Add water to the fermented material, mix it evenly, pile the fermented material into a fermented pile with a length of 4 meters, a width of 0.8 meters and a height of 0.5 meters, and ferment for 8 days to obtain a fermentation product;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com