A barite anti-radiation concrete

A barite and anti-radiation technology, applied in the field of building materials, can solve the problems of affecting the anti-radiation ability of concrete, easy to produce cracks, affecting the concrete strength, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

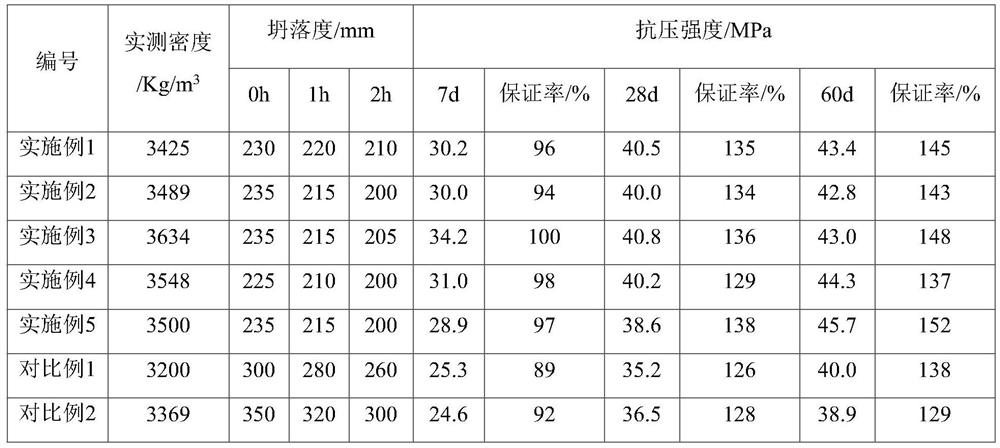

Examples

preparation example 1

[0035] (1) by comprising the compound of 4-butylaminobenzoic acid nine polyethylene glycol monomethyl ether ester-maleic anhydride-lignosulfonate calcium polymer graft copolymer 15Kg, polyethylene glycol 15Kg and acrylic acid 2.5Kg React in the presence of water at 80°C for 5 hours and dry to obtain mixture A;

[0036](2) React the mixture comprising the mixture A of step (1), 2.5Kg of acrylic acid and 15Kg of water glass in the presence of water at 80°C for 4 hours, and cool to 40°C to obtain mixture B;

preparation example 2

[0038] (1) by comprising the compound of 4-butylaminobenzoic acid nine polyethylene glycol monomethyl ether ester-maleic anhydride-calcium lignosulfonate polymer graft copolymer 18Kg, Polyethylene Glycol 8Kg and acrylic acid 3.5Kg React in the presence of water at 90°C for 6 hours and dry to obtain mixture A;

[0039] (2) React the mixture comprising the mixture A of step (1), 3.5Kg of acrylic acid and 18Kg of water glass in the presence of water at 85°C for 5 hours, and cool down to 45°C to obtain mixture B;

preparation example 3

[0041] (1) by the mixture comprising 4-butylaminobenzoic acid nine polyethylene glycol monomethyl ether ester-maleic anhydride-lignosulfonate calcium polymer graft copolymer 20Kg, Polyethylene Glycol 10Kg and acrylic acid 5Kg React in the presence of water for 7 hours at 99°C and dry to obtain mixture A;

[0042] (2) React the mixture comprising the mixture A of step (1), 3.5Kg of acrylic acid and 18Kg of water glass in the presence of water at 90°C for 6 hours, and cool down to 50°C to obtain mixture B;

[0043] (3) Add 3Kg of defoamer to the mixture B of step (2), and use sodium bicarbonate to adjust the pH value to 9.0 to obtain a water reducer; Preparation example 1 of retarder: mix sodium gluconate 5Kg, ( L+)-10Kg of tartaric acid, 2Kg of sodium citrate, 2Kg of maleic anhydride-acrylic acid copolymer, 10Kg of pumice powder, and 0.3Kg of calcium sugar are uniformly mixed.

[0044] Preparation example 2 of retarder: 6Kg of sodium gluconate, 12Kg of (L+)-tartaric acid, 3Kg ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com