Method for constructing device for removing nitrogen and phosphorus from sewage, device for removing nitrogen and phosphorus and method for removing nitrogen and phosphorus

A technology for nitrogen and phosphorus removal and construction method, which is applied in the field of nitrogen and phosphorus removal devices for sewage, and can solve problems such as increased treatment costs, secondary pollution, and low carbon-to-nitrogen ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

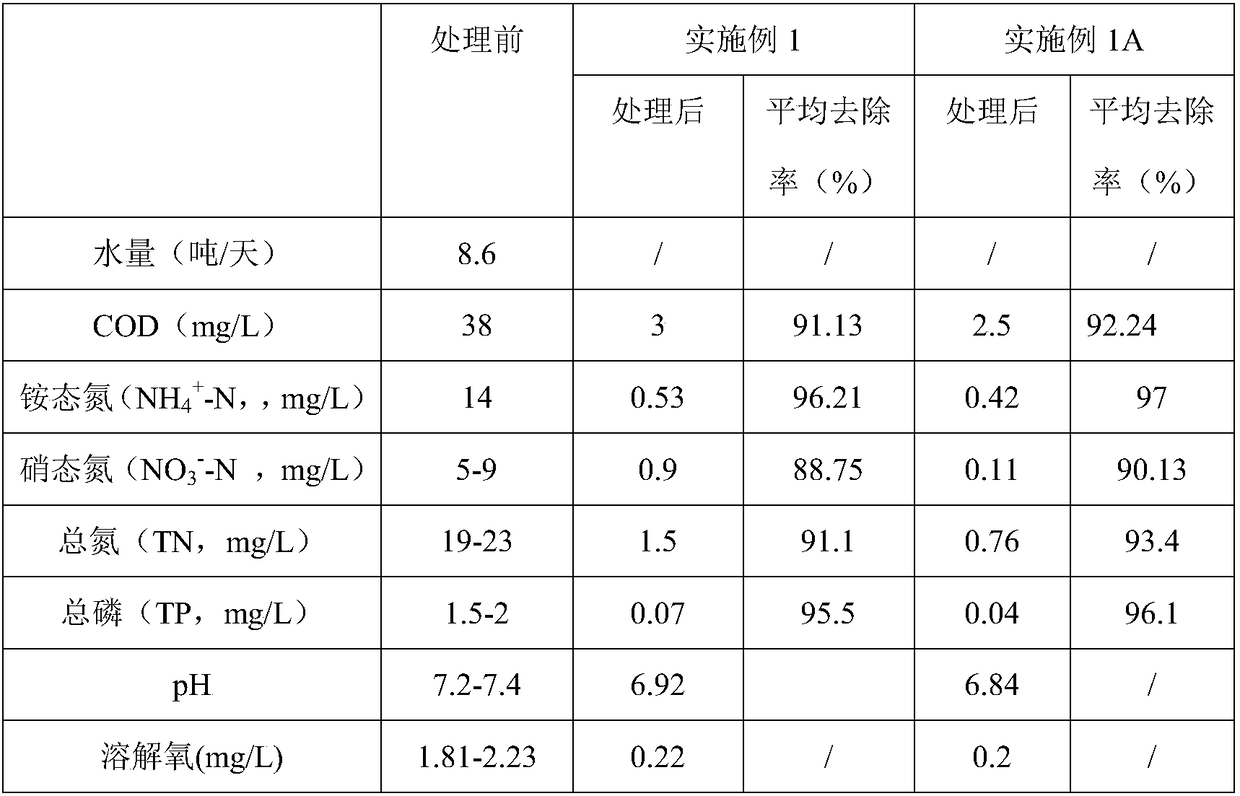

Embodiment 1

[0120] 1. Fill the tank

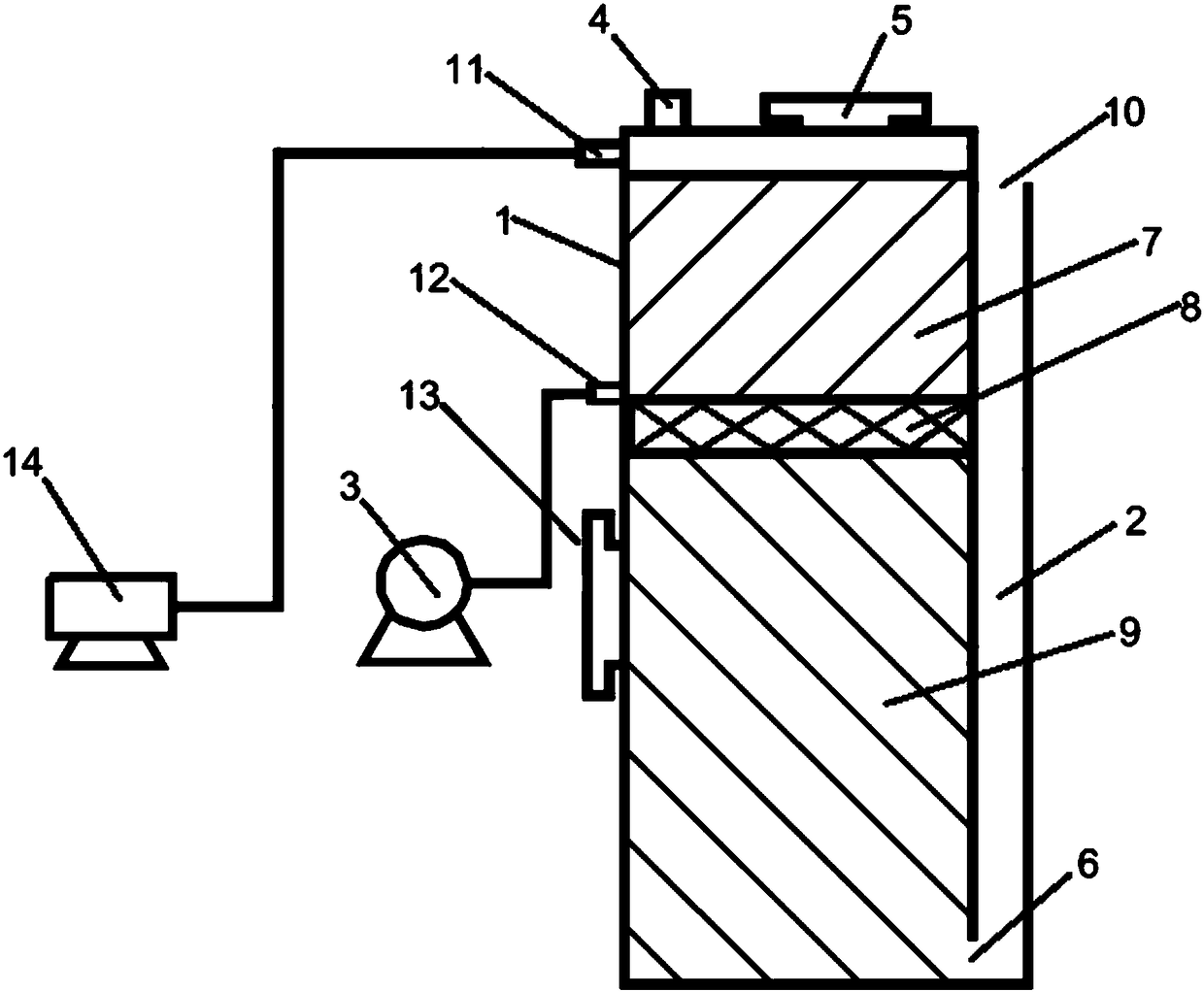

[0121] Such as figure 1 As shown, the tank body of the denitrification and dephosphorization device of the present invention is a cuboid, and the top of the tank body of the denitrification and dephosphorization tank is provided with an exhaust port; in the tank body, it is divided into an upper packing area, a supporting area, and a lower part from top to bottom. packing area. The water outlet tank is arranged on the right side of the tank body, the bottom of the water outlet tank is connected with the lower part of the tank body, and the purified outlet water in the tank body after passing through the upper and lower packing layers flows into the water outlet tank from the overflow port, and then is discharged from the upper part of the water outlet tank.

[0122] Wherein, the height inside the tank body of the denitrification and phosphorus removal tank is 100cm, wherein the height of the upper filling area is 30cm, and the upper filling is a mixt...

Embodiment 1A

[0137] In addition to step 3) in the denitrification and dephosphorization treatment step, the hydraulic retention time of the sewage in the device is controlled to be 4h. During the operation of the system, the temperature is maintained at 25-30°C, the pH of the influent is basically maintained at 7.3-7.6, and the DO is basically maintained at 1.8. Except between -2.2, all the other are identical with embodiment 1.

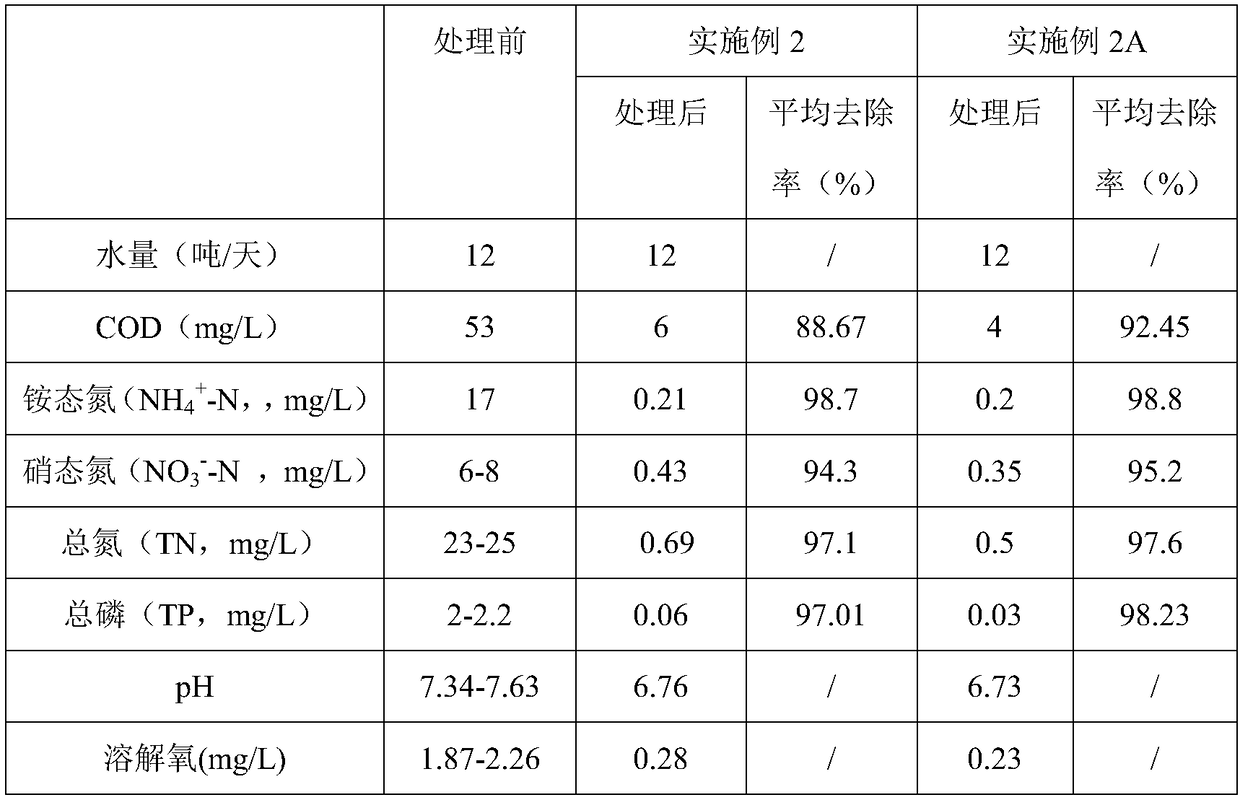

Embodiment 2

[0139] 1. Fill the tank

[0140] Same as Example 1.

[0141] 2. Hanging film treatment

[0142] 2-1), after the anaerobic activated sludge and the aerobic activated sludge of the municipal sewage treatment plant are respectively concentrated, the concentrated activated sludge is made, wherein the MLSS concentration of the concentrated activated sludge is 18000-20000mg / L (preferably 19000mg / L);

[0143] 2-2) Inject anaerobic activated sludge into the lower filling area of the tank, inject aerobic activated sludge into the upper filling area until the filling layer is completely submerged, then turn on the aerator and control the aeration rate to 1L / min (usually 1-2L / min) and then soak for 1.5h (usually 1-2h);

[0144] 2-3) After soaking, the sewage with the C / N ratio≤2 of the sewage treatment plant is injected from the water inlet on the top of the tank body of the device of the present invention, and the water flow is downward flow, flowing through the upper packing area,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com