Atomic-thickness graphene/boron nitride composite heterogeneous film transferring method

A thin film transfer, graphene technology, applied in the direction of graphene, nitrogen compounds, chemical instruments and methods, etc., can solve the problems of wash away, graphene pores, sample performance deterioration, etc., to achieve good environmental adaptability, simple process, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described clearly and completely in conjunction with the accompanying drawings of the embodiments. The description of this specification combined with specific implementation cases does not constitute any limitation on the invention. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative work shall fall within the protection scope of the present invention.

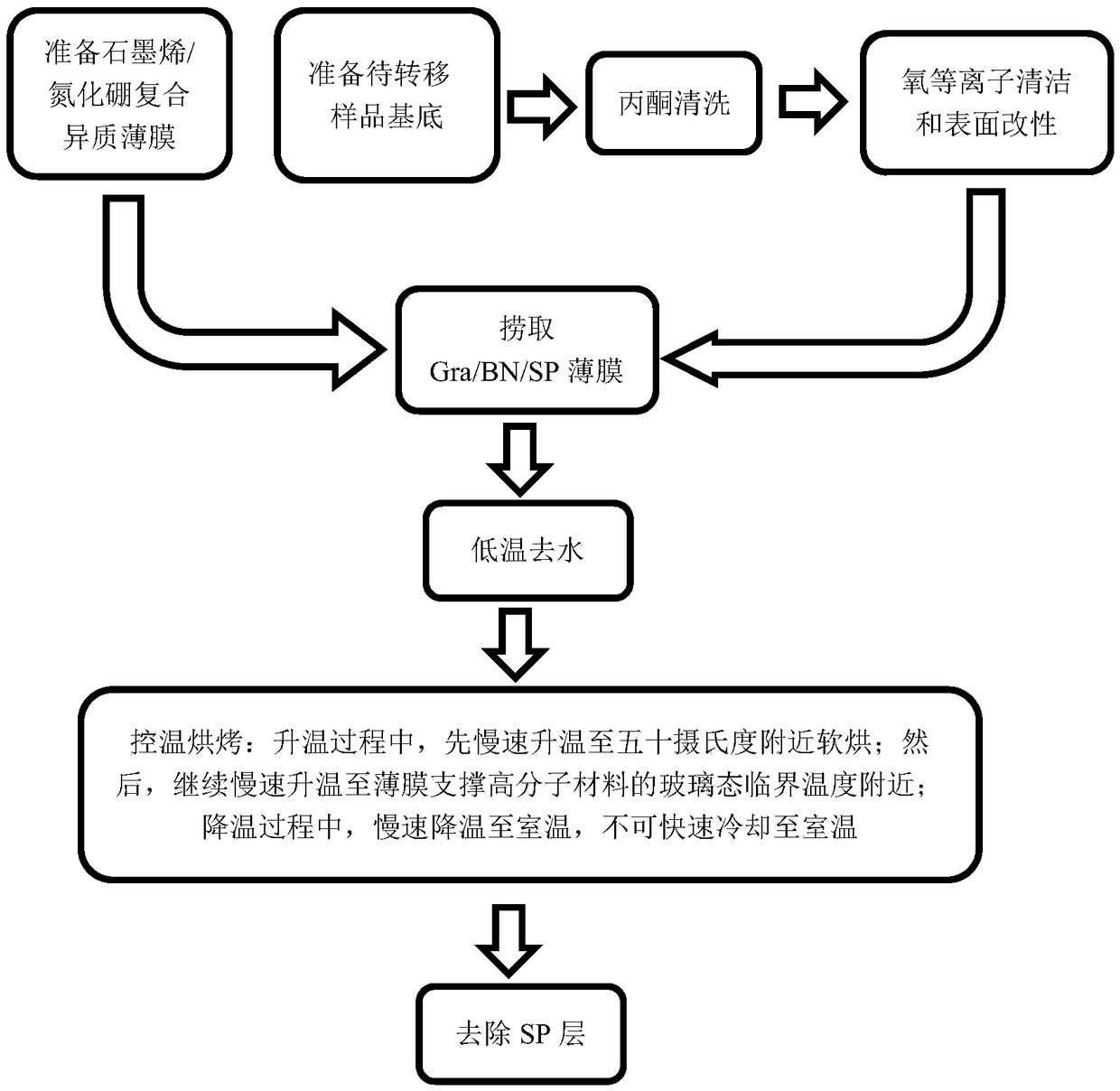

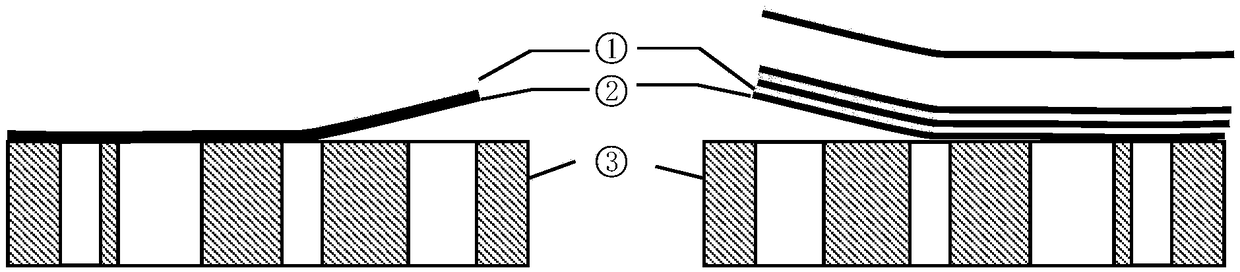

[0028] The invention provides a graphene / boron nitride composite heterogeneous film transfer method, figure 2 The graphene / boron nitride composite heterogeneous film bilayer and multilayer diagram. figure 2 Among them, ① represents boron nitride, ② is graphene, and ③ is the sample substrate. Process flow chart such as figure 1 As shown, it is characterized in that, during the lamination process, the low-temperature natural water removal and the slow heating rate prevent the formation of bubbles between Gra and B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com