A fully automatic cable coiling machine

A cable tie machine, fully automatic technology, applied in the parts of strapping machinery, thin material processing, packaging, etc., can solve the problems of slow wire take-up speed, high labor intensity, inconvenient use in the later stage, etc., to achieve fast wire take-up speed, The effect of low labor intensity and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

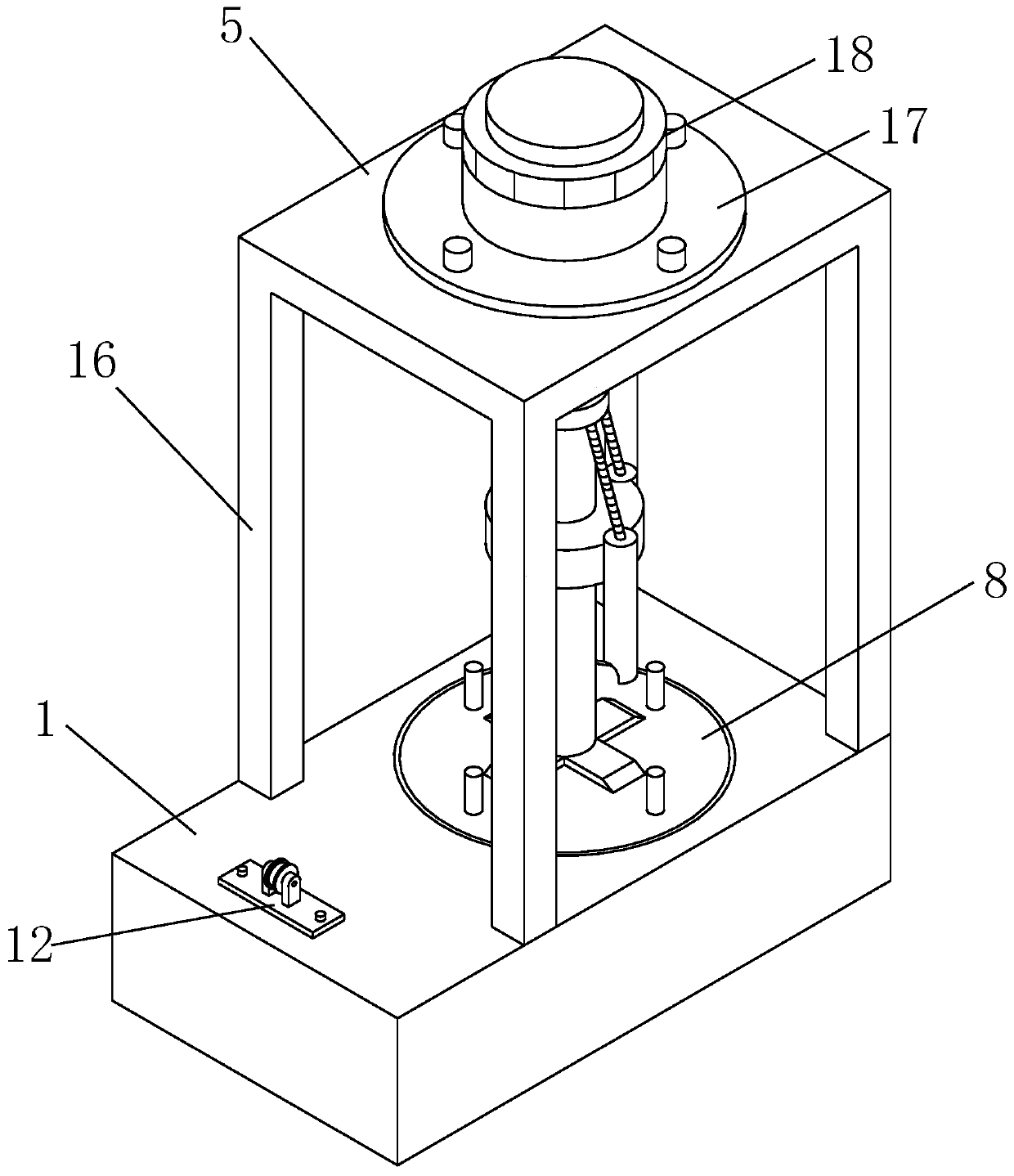

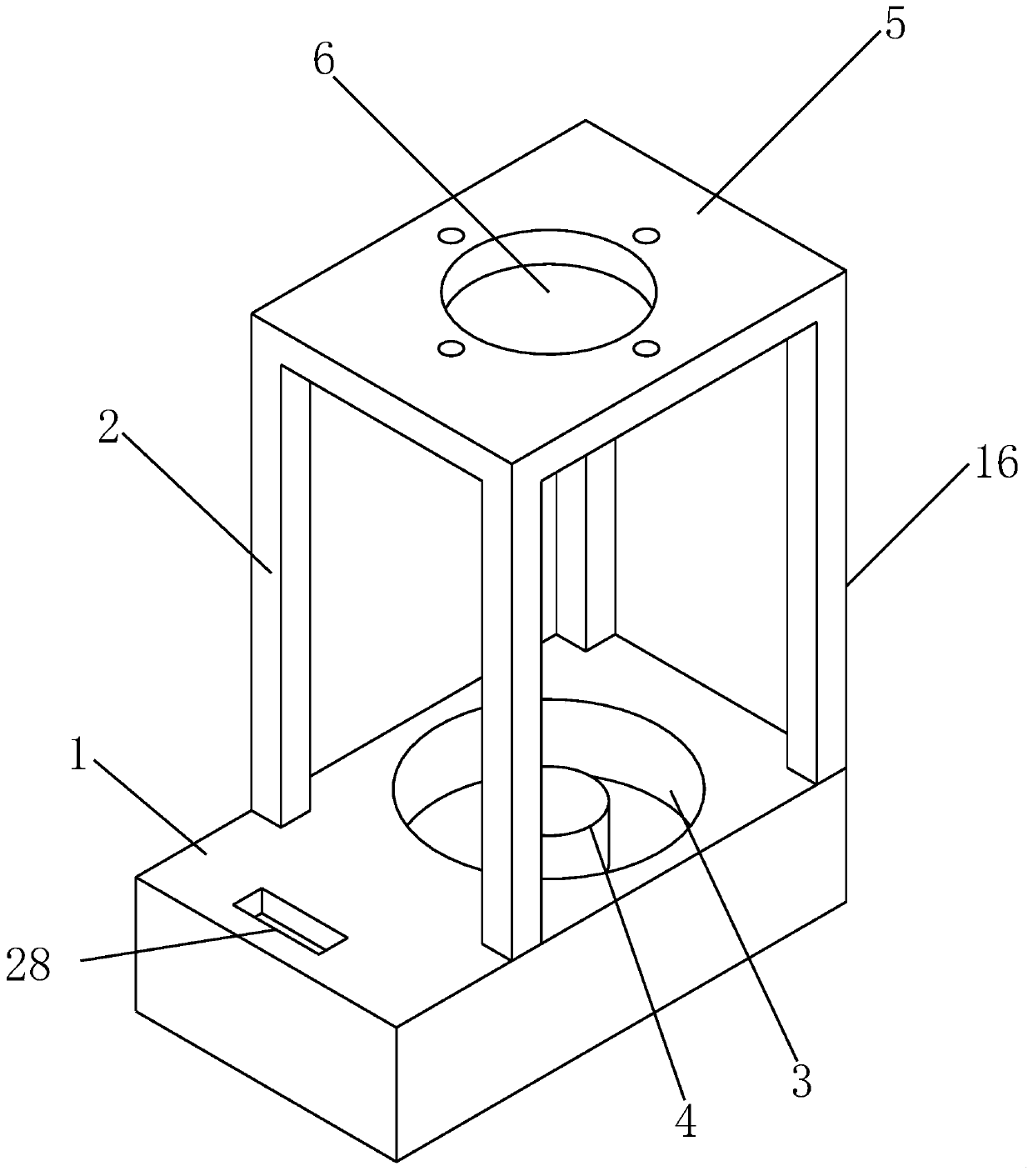

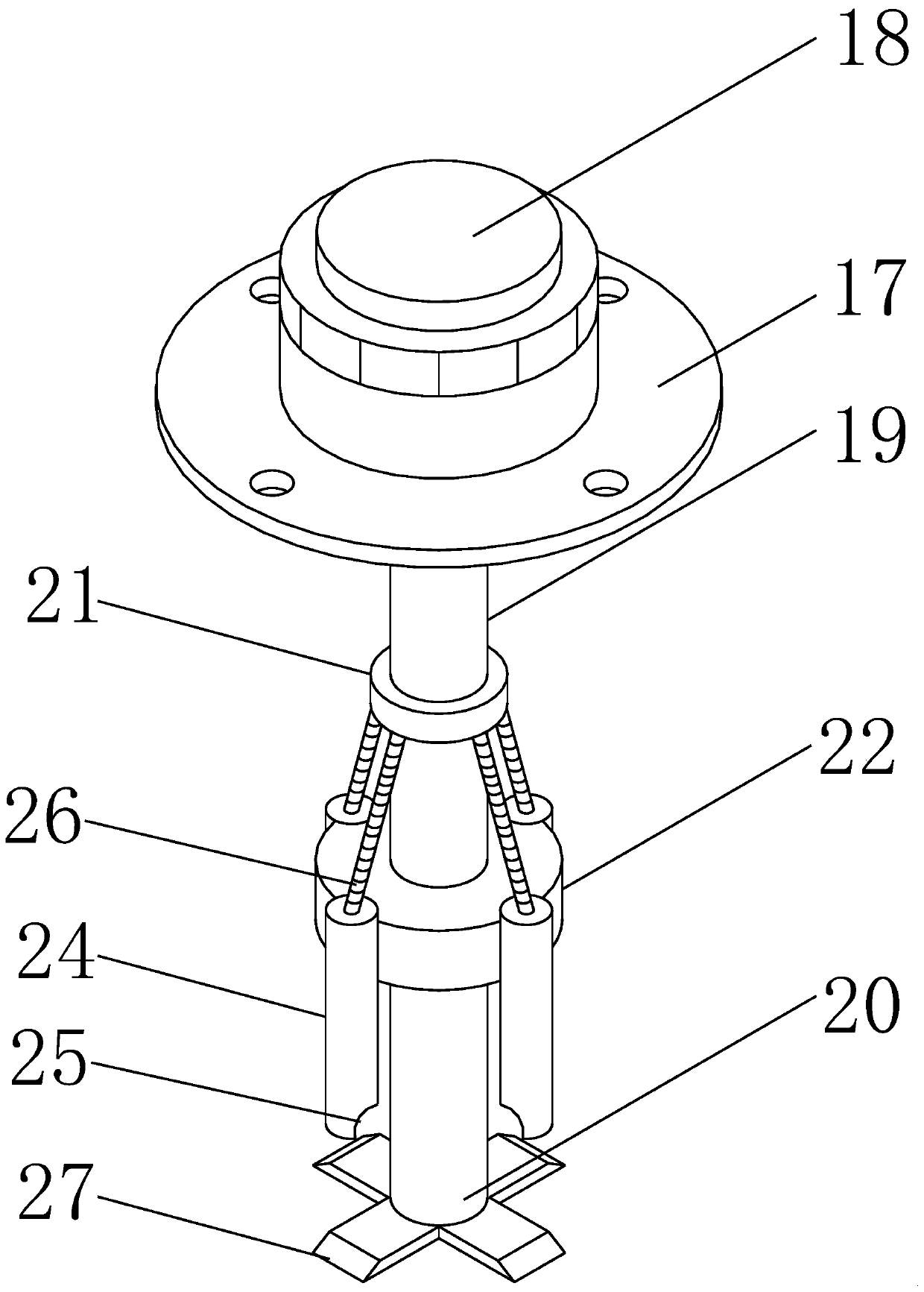

[0021] A fully automatic cable coiling machine, comprising a device base 1, the top of the device base 1 is provided with a combing device and a manipulator fixing frame 2 arranged on one side of the combing device, and the inside of the manipulator fixing frame 2 corresponds to The upper surface of the device base 1 is provided with a first installation hole 3, the center of the first installation hole 3 is provided with a rotating shaft 4, and a second installation hole 3 is provided on the fixing plate 5 of the manipulator holder 2 corresponding to the top of the first installation hole 3. Mounting hole 6, the second mounting hole 6 is equipped with a manipulator unit; the inside of the first mounting hole 3 is connected to the turntable device 8 through the bearing 7, and the bottom of the turntable device 8 is provided with a rotating shaft that is compatible with the rotating shaft 4 Hole 9, the middle position of the upper surface of the turntable device 8 is provided wi...

Embodiment 2

[0023]A fully automatic cable coiling machine, comprising a device base 1, the top of the device base 1 is provided with a combing device and a manipulator fixing frame 2 arranged on one side of the combing device, and the inside of the manipulator fixing frame 2 corresponds to The upper surface of the device base 1 is provided with a first installation hole 3, the center of the first installation hole 3 is provided with a rotating shaft 4, and a second installation hole 3 is provided on the fixing plate 5 of the manipulator holder 2 corresponding to the top of the first installation hole 3. Mounting hole 6, the second mounting hole 6 is equipped with a manipulator unit; the inside of the first mounting hole 3 is connected to the turntable device 8 through the bearing 7, and the bottom of the turntable device 8 is provided with a rotating shaft that is compatible with the rotating shaft 4 Hole 9, the middle position of the upper surface of the turntable device 8 is provided wit...

Embodiment 3

[0025] A fully automatic cable coiling machine, comprising a device base 1, the top of the device base 1 is provided with a combing device and a manipulator fixing frame 2 arranged on one side of the combing device, and the inside of the manipulator fixing frame 2 corresponds to The upper surface of the device base 1 is provided with a first installation hole 3, the center of the first installation hole 3 is provided with a rotating shaft 4, and a second installation hole 3 is provided on the fixing plate 5 of the manipulator holder 2 corresponding to the top of the first installation hole 3. Mounting hole 6, the second mounting hole 6 is equipped with a manipulator unit; the inside of the first mounting hole 3 is connected to the turntable device 8 through the bearing 7, and the bottom of the turntable device 8 is provided with a rotating shaft that is compatible with the rotating shaft 4 Hole 9, the middle position of the upper surface of the turntable device 8 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com