Novel slurry spraying unit

A shotcrete and unit technology, applied in loading/unloading, transportation and packaging, packaging, etc., can solve the problems affecting the health and personal safety of on-site workers, polluting the environment with dust, threatening the health of workers, etc., to improve attention and safety, reduce noise pollution, and eliminate the effects of dust spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

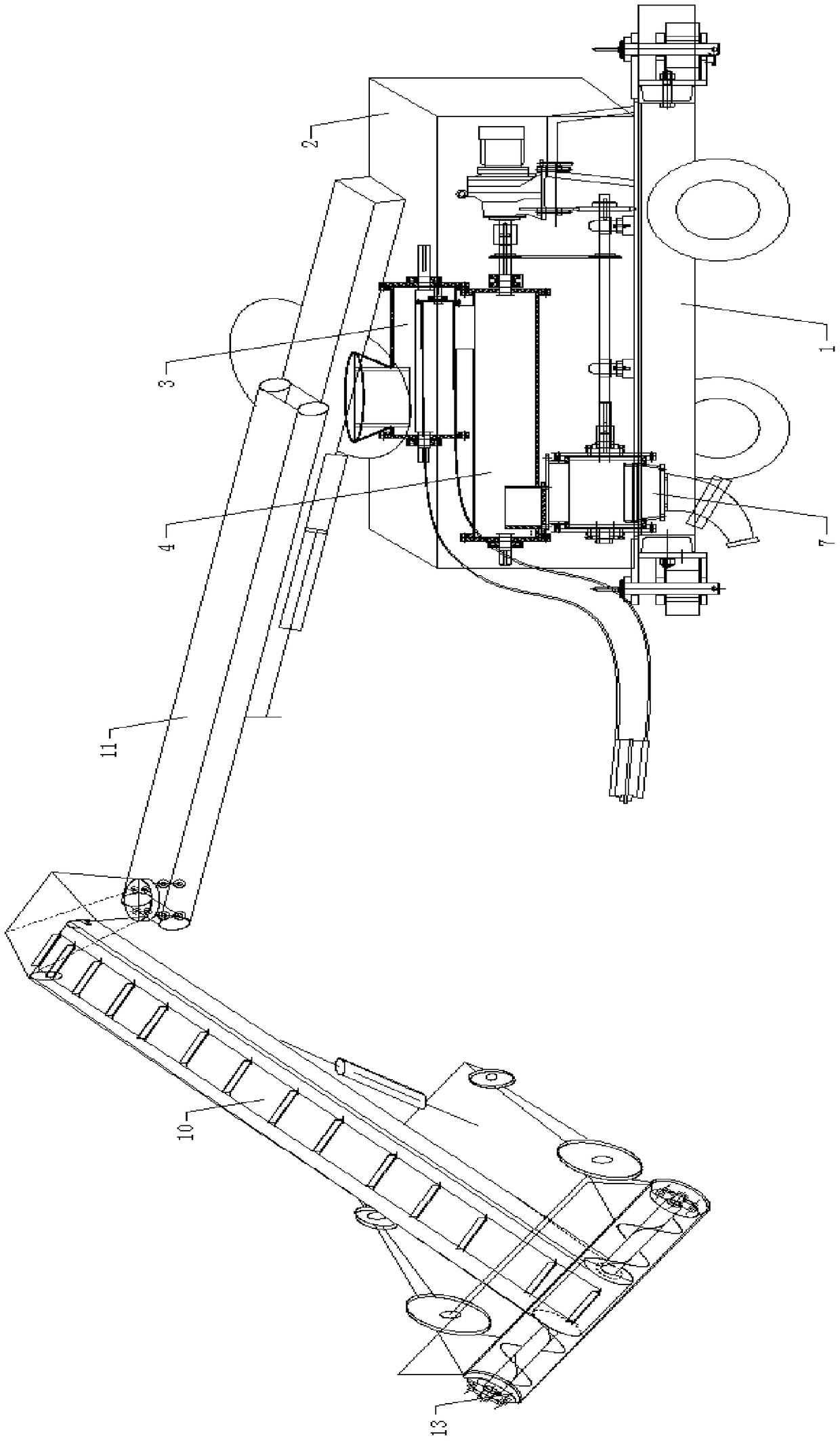

[0032] Below in conjunction with accompanying drawing, by describing embodiment, the present invention will be further described:

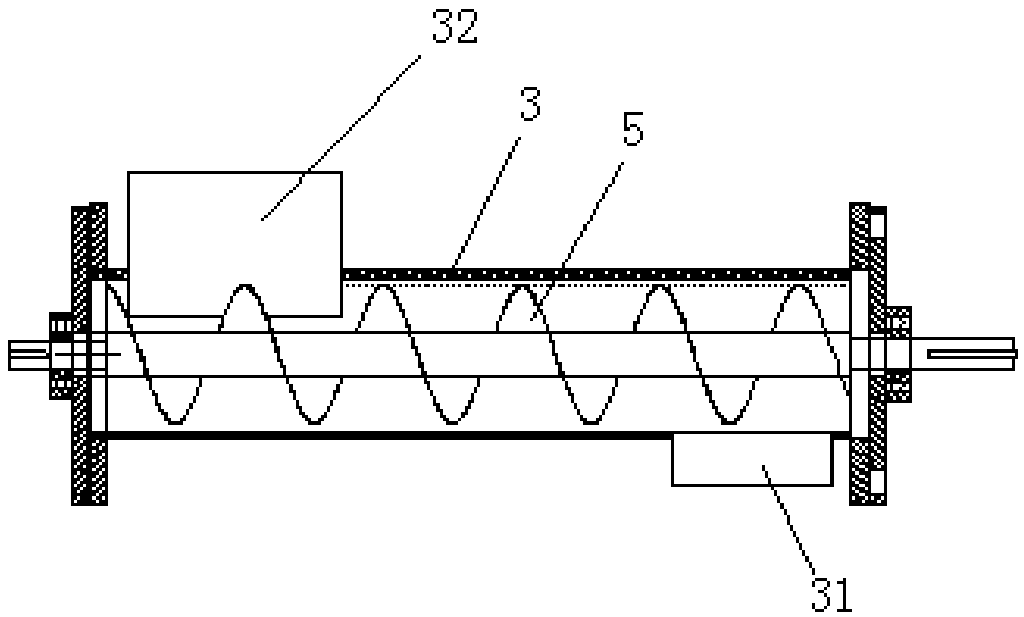

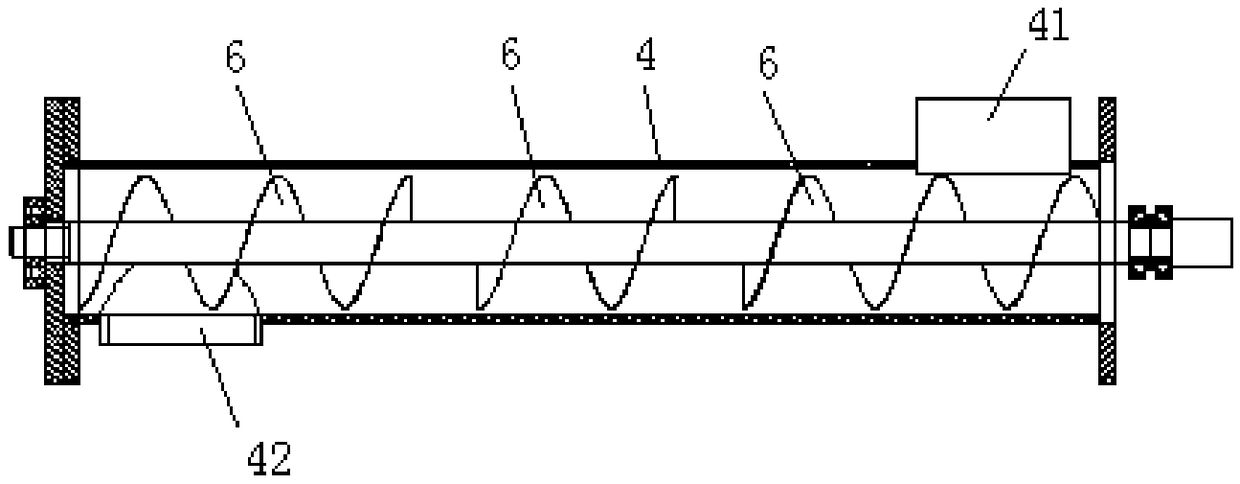

[0033] Such as Figure 1-7 As shown, a new type of spraying unit of the present invention includes a mobile base 1 and a spraying unit 2 . Wherein, the spraying unit 2 includes a feeding mechanism, a batching auger 3 and a stirring auger 4 . The feeding mechanism, the batching auger 3 and the stirring auger 4 are all airtight housings. The feeding mechanism and the batching auger 3 are set in pairs, and there are at least two pairs; the batching auger 3 is arranged parallel to the horizontal plane.

[0034] There are three batching augers 3 of the present invention, one stirring auger 4, and the included angle between the batching auger 3 and the stirring auger cage 4 is 0-90°. In the present embodiment, the batching auger 3 and The mixing augers 4 are all installed horizontally, that is, the angle between the batching auger 3 and the horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com