Fully-automatic pipette suction tip filling machine

A pipette tip and filling machine technology, which is applied in the directions of packaging automatic control, packaging, packaging protection, etc., can solve the problems of low filling efficiency, single filling tip specification, and low degree of automation of tip filling equipment, and achieves automation. High-level, high-compatibility effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

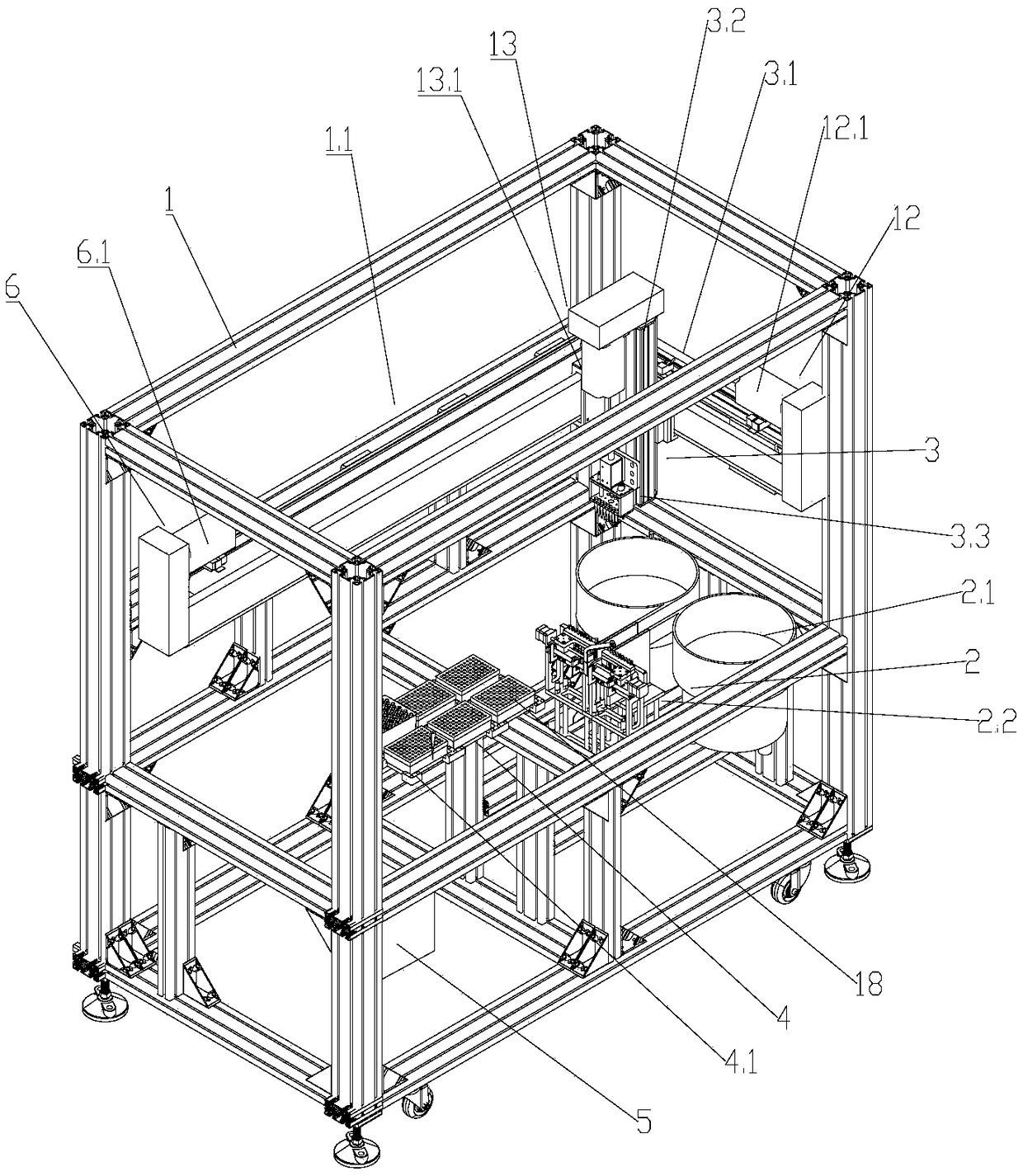

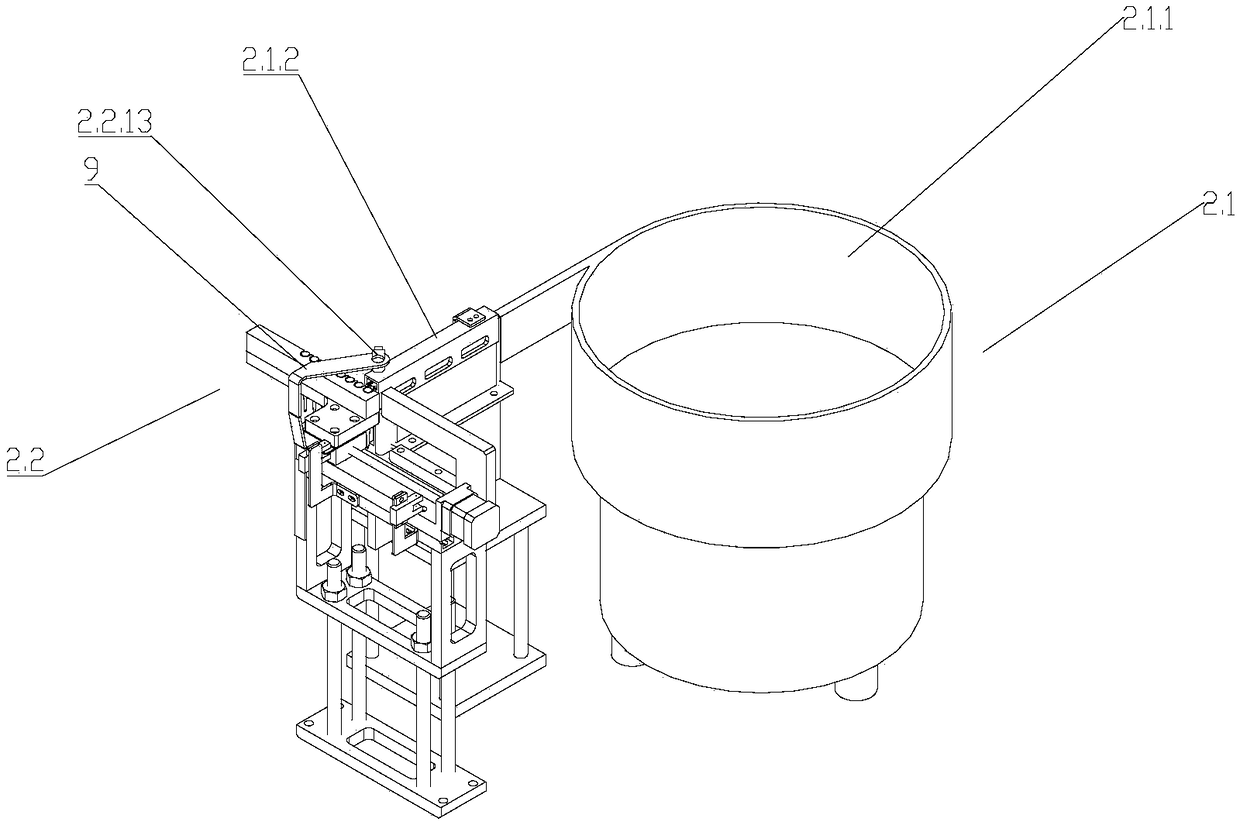

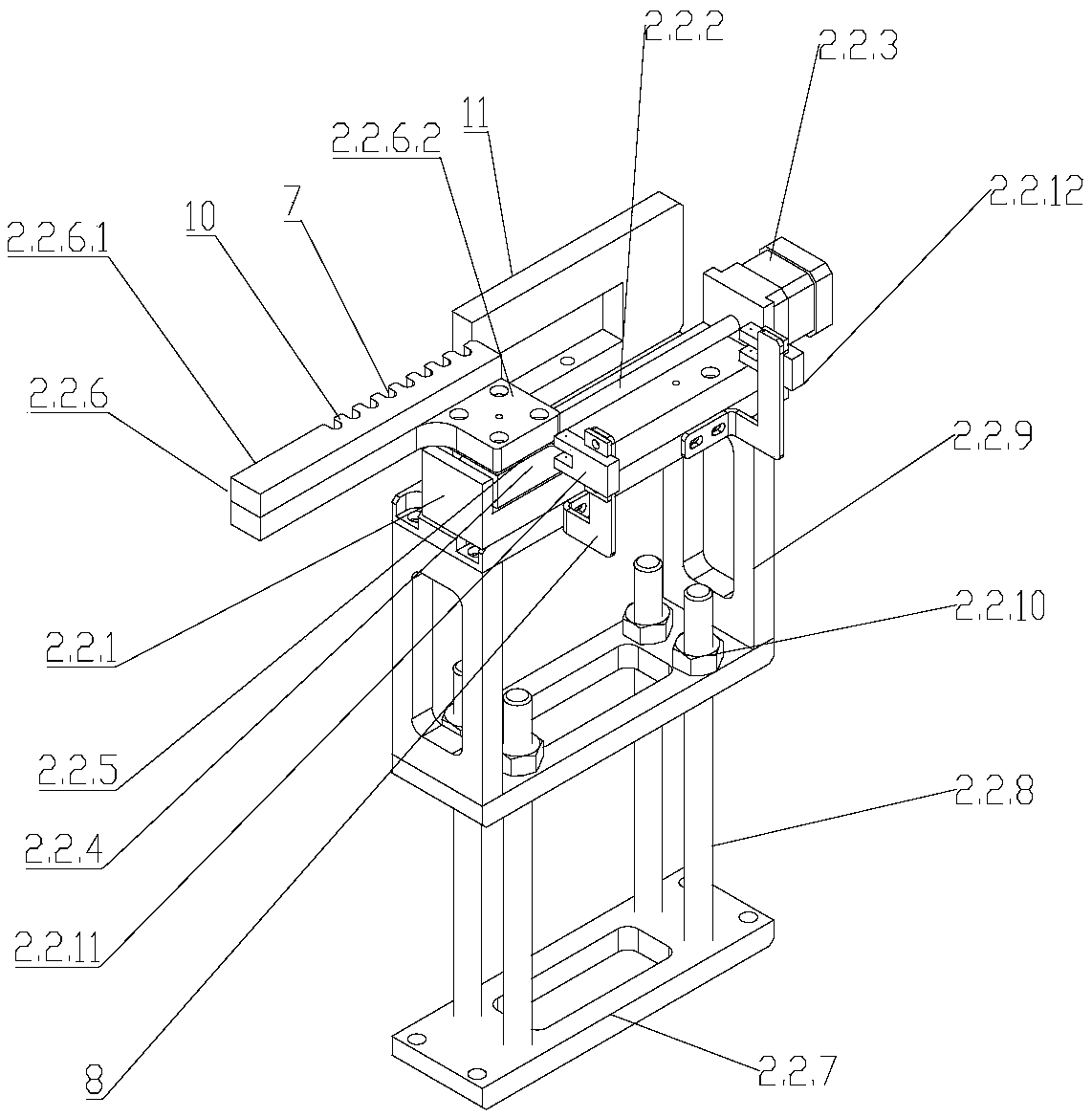

[0031] A fully automatic pipette tip filling machine, such as figure 1 As shown, it includes a frame 1, a sorting and distributing unit 2, a retrieving unit 3, a tip box placement plate 4, and an electric control box 5. For ease of description, in this embodiment, the inventor defines the length direction of the rack as the X axis, the width direction of the rack as the Y axis, and the height direction of the rack as the Z axis.

[0032] In this embodiment, an X-axis moving guide rail 1.1 is fixed on the rear side of the frame 1 along the length direction of the frame, that is, the X-axis. A first driving device 6 is installed in the X-axis moving guide rail 1.1. Specifically, the first driving device 6 includes a first driving motor 6.1, a first screw mandrel driven by the first driving motor, a first screw nut threadedly connected with the first screw mandrel, and a screw nut fixed to the first screw mandrel. Material unit 3. Wherein, the first driving motor 6.1 is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com