High-precision hard and brittle material coil skeleton turning and milling composite processing technology and tooling

A technology of coil skeleton and hard and brittle materials, applied in the direction of stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problems of low processing efficiency, increase processing difficulty, increase processing difficulty, etc., to improve processing quality, improve The effect of machining quality, improving machining efficiency and machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

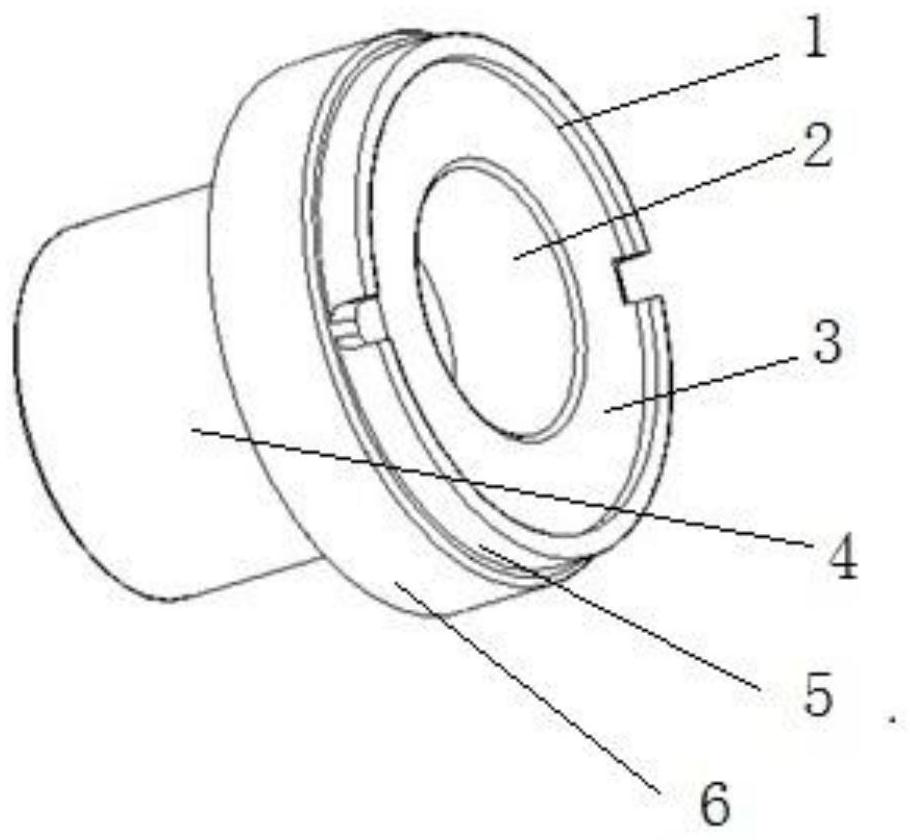

[0034] In order to facilitate the understanding of the processing technology of the present invention, the tooling used in the present invention is first introduced:

[0035] A high-precision hard and brittle material coil skeleton turning and milling compound processing tooling, including positioning seat 20, gland 1 7, gland 2 11, gland 3 16, fastening screw 14 and fastening screw 2 19, the front end of the positioning seat Gland 1 is installed coaxially on the outer side of the positioning seat, and Gland 2 is coaxially installed on the inner side of the front end of the positioning seat through fastening screws. Two front ends. The structure of each component is described in detail below:

[0036] (1) The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com