Leveling mechanism for vehicle-mounted automatic leveling device

A leveling mechanism and automatic leveling technology, applied in the parts of the instrument, non-rotating vibration suppression, instruments, etc., can solve the problems of low efficiency, inconvenient operation and use, etc., to improve smooth transition and stability, prevent stuck effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

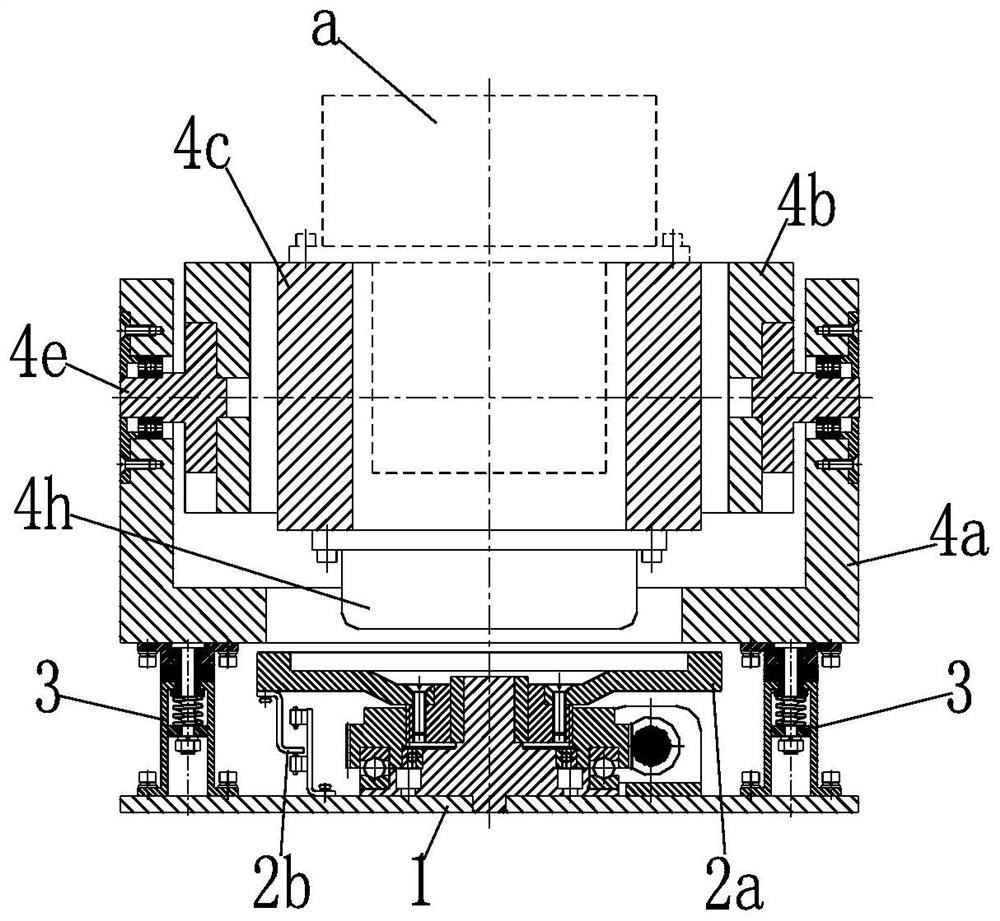

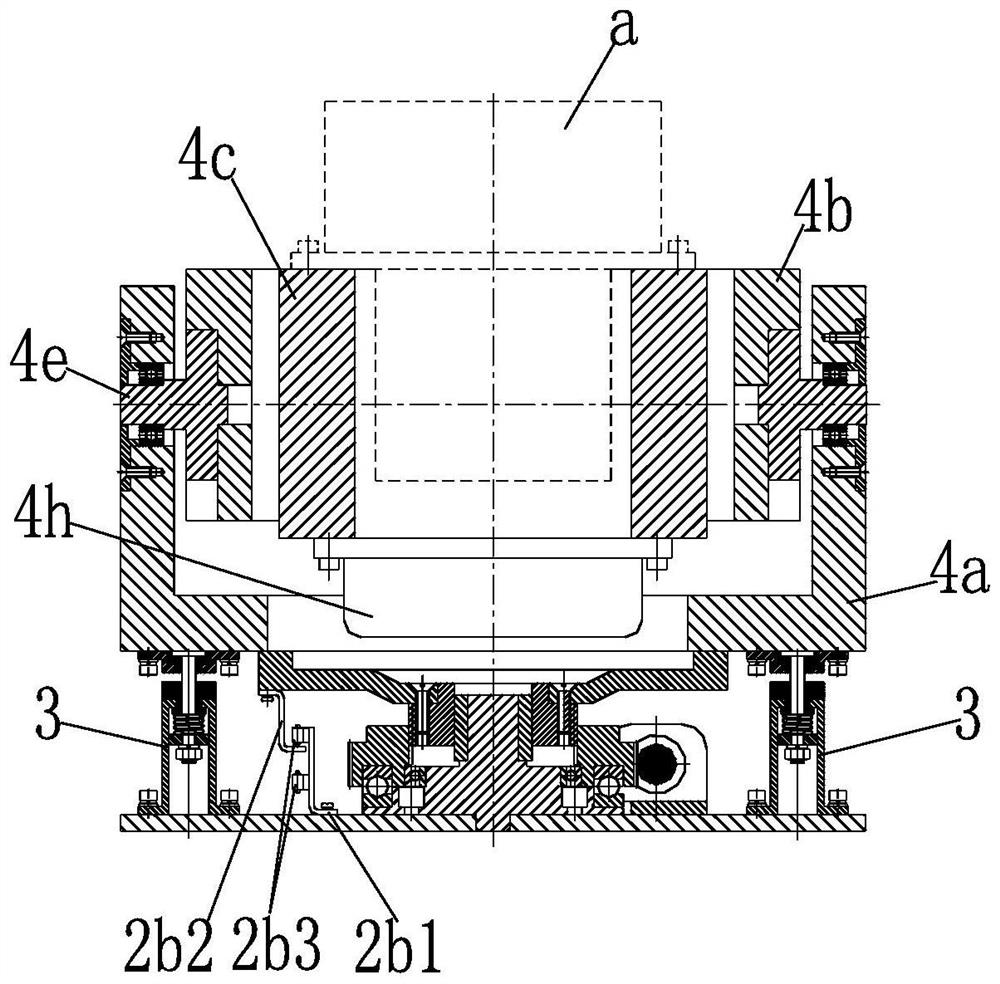

[0089] This embodiment provides a leveling mechanism for a vehicle-mounted automatic leveling device, including an outer frame 4a, a middle frame 4b, and an inner frame 4c, and the top surface of the inner frame 4c is an instrument installation for installing a precision instrument a On the other hand, the two sides of the inner frame 4c are rotatably installed in the middle frame 4b through an inner frame rotating shaft 4d respectively, and the two sides of the middle frame 4b are respectively rotatably installed through a middle frame rotating shaft 4e In the outer frame 4a, the rotation direction of the inner frame 4c is arranged perpendicular to the rotation direction of the middle frame 4b, and there is a set between the outer frame 4a and the middle frame 4b for adjusting the middle frame 4b. A middle frame leveling component 4f for levelness, an inner frame leveling component 4g for adjusting the levelness of the inner frame 4c is provided between the middle frame 4b and...

Embodiment 2

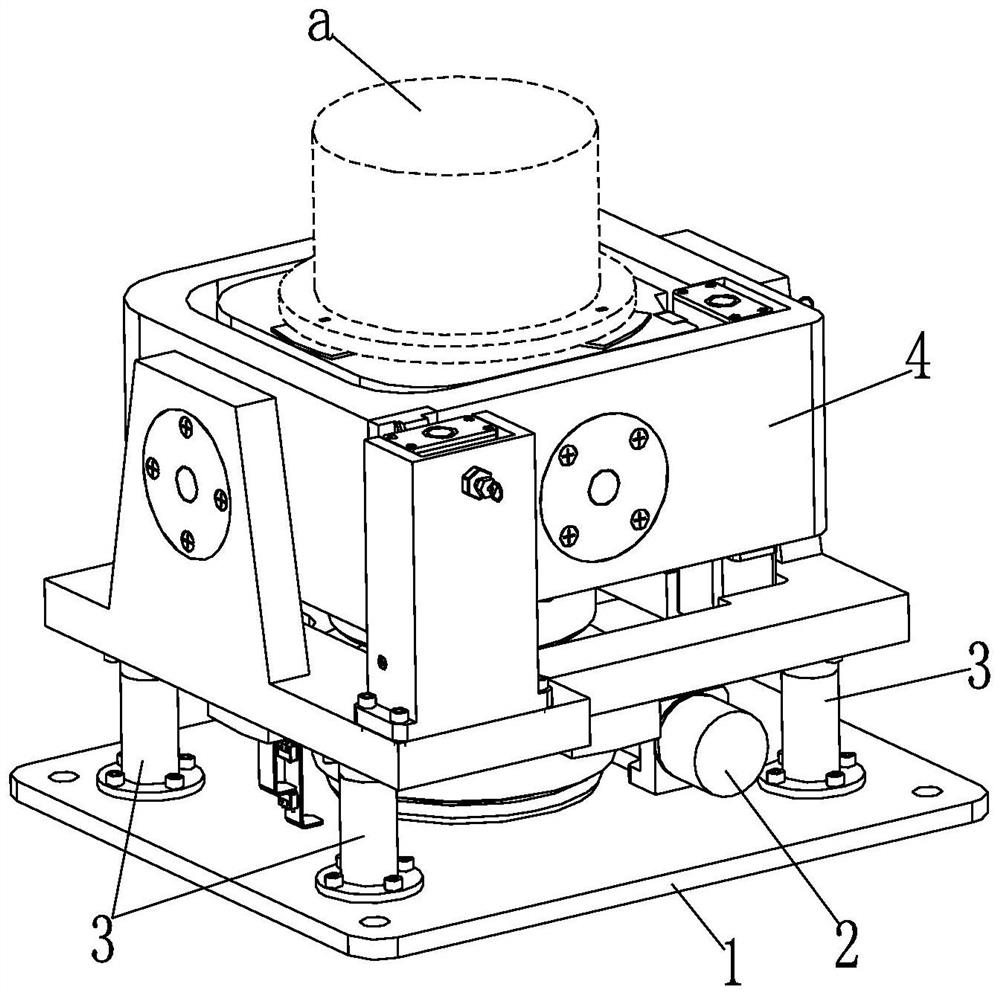

[0109] This embodiment provides a vehicle-mounted automatic leveling device, including a base 1 and a jacking mechanism 2 installed on the base 1, a leveling mechanism 4 is installed on the base 1 through a shock absorbing mechanism 3, and the leveling mechanism 4 is installed on the base 1. The leveling mechanism 4 is located above the jacking mechanism 2. When the jacking plate 2a of the jacking mechanism 2 is at the lowest position, the jacking plate 2a is spaced apart from the bottom surface of the leveling mechanism 4. When the lifting plate 2a of the mechanism 2 is at the highest position, the lifting plate 2a is against the bottom surface of the leveling mechanism 4 . When the leveling device is in use, the precision instrument a is installed on the leveling mechanism 4. When the leveling device is in the shock-absorbing state, the jacking plate 2a of the jacking mechanism 2 is arranged at intervals from the bottom surface of the leveling mechanism 4. , the damping mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com