Inner frame leveling assembly for vehicle-mounted automatic leveling device

An automatic leveling and leveling technology, applied in the field of machinery, can solve the problems of inconvenient operation and low efficiency, and achieve the effects of convenient maintenance, reduction of manufacturing costs, and prevention of jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

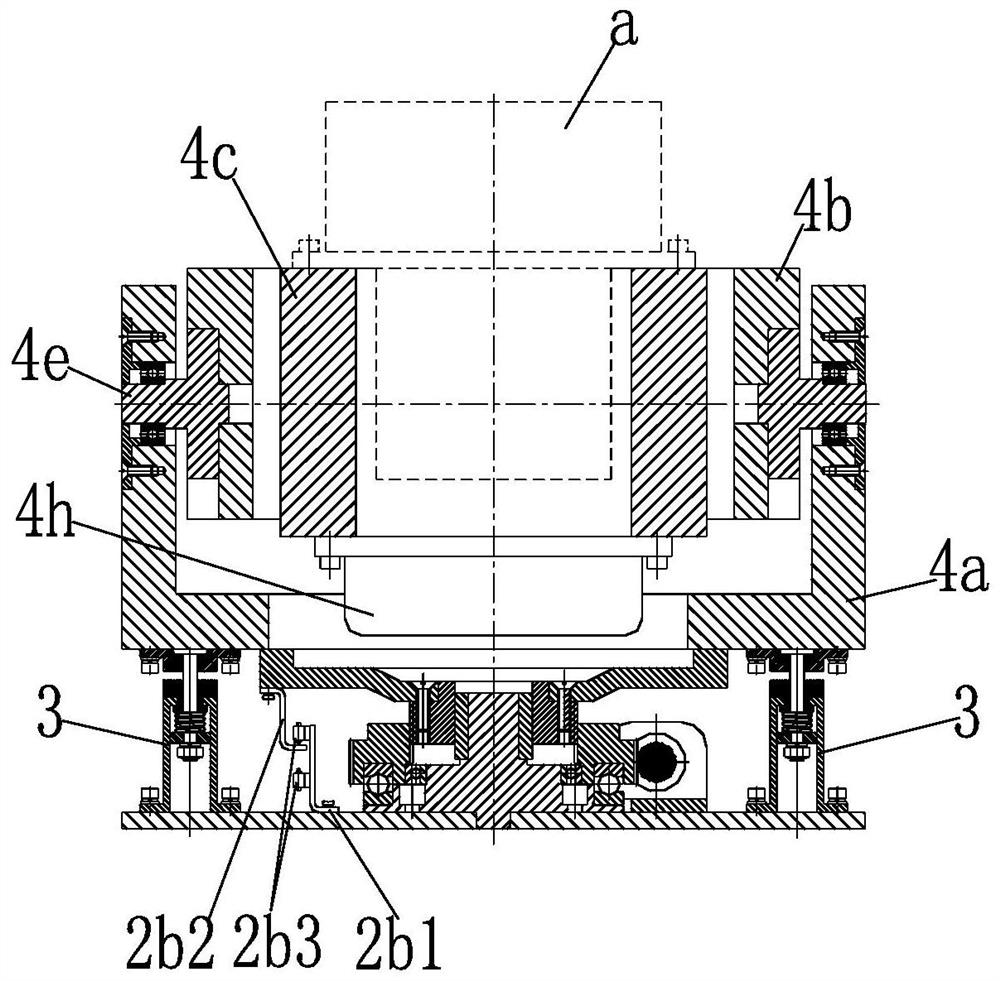

[0057] This embodiment provides an inner frame leveling assembly for a vehicle-mounted automatic leveling device, including an inner frame leveling seat 4g2, an inner frame worm shaft 4g3, an inner frame leveling motor 4g4, and an inner frame leveling gear 4g5, assembled , the inner frame leveling seat 4g2 is installed in the U-shaped groove on the inner surface of the middle frame 4b, the opening of the U-shaped groove faces the inner frame 4c, and the inner frame leveling seat 4g2 is a cylindrical structure, so The lower end of the inner frame leveling seat 4g2 is rotatably installed in the corresponding position in the U-shaped groove, the rotation direction of the inner frame leveling seat 4g2 faces the opening of the U-shaped groove and the inner frame leveling seat The rotation direction of 4g2 is consistent with the rotation direction of the inner frame 4c, and the inner frame worm shaft 4g3 is installed in the inner frame leveling seat 4g2 in a rotatable manner along th...

Embodiment 2

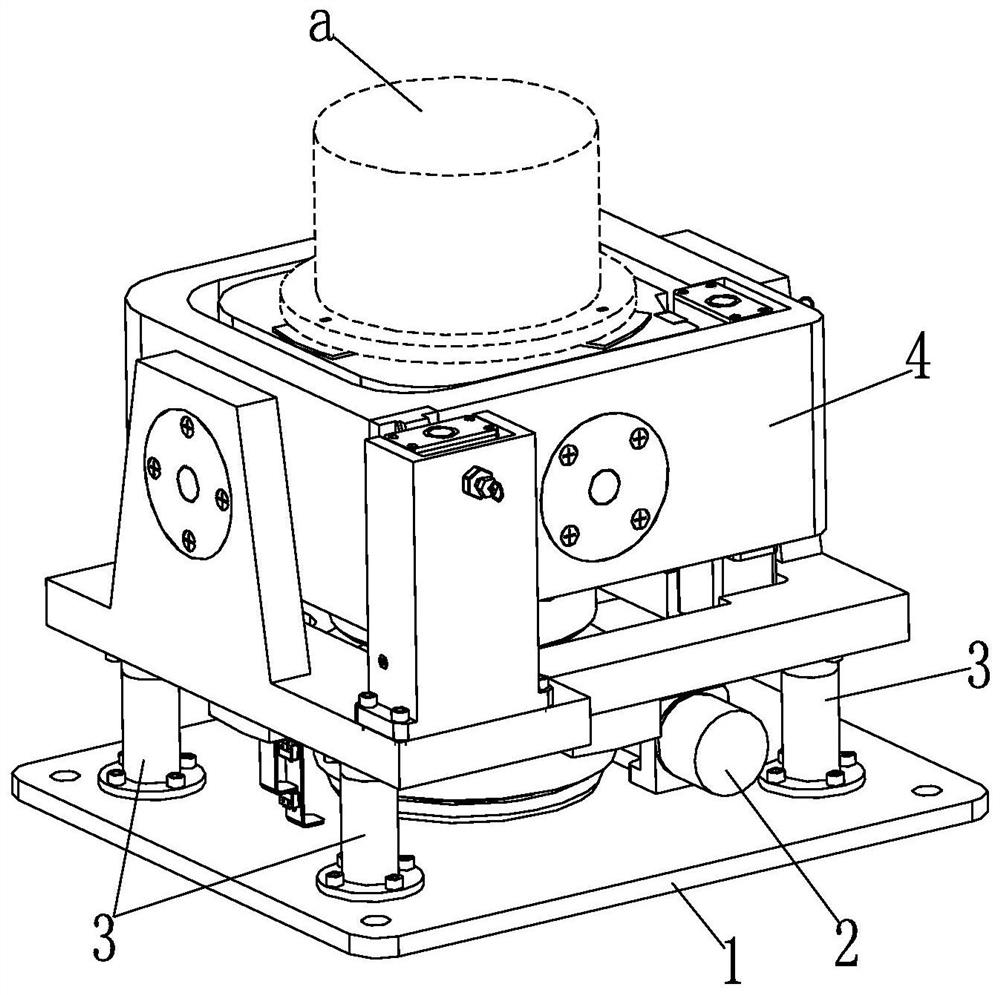

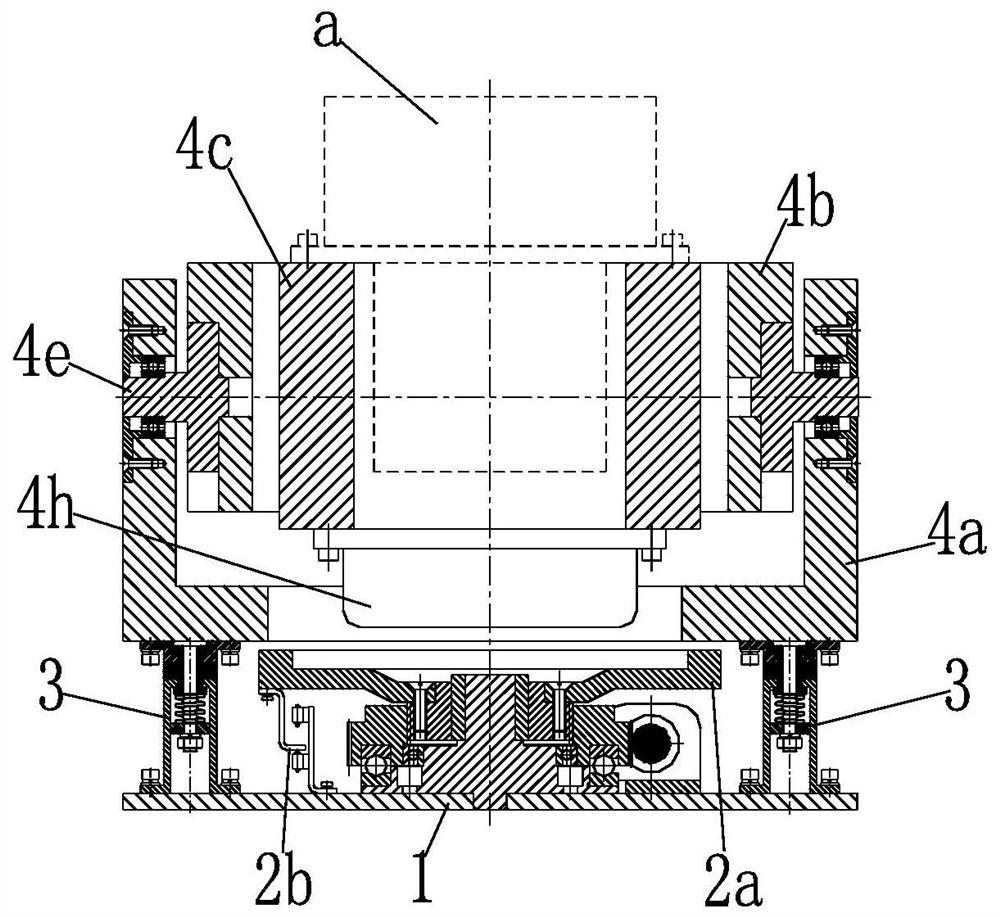

[0067] This embodiment provides a vehicle-mounted automatic leveling device, including a base 1 and a jacking mechanism 2 installed on the base 1, a leveling mechanism 4 is installed on the base 1 through a shock absorbing mechanism 3, and the leveling mechanism 4 is installed on the base 1. The leveling mechanism 4 is located above the jacking mechanism 2. When the jacking plate 2a of the jacking mechanism 2 is at the lowest position, the jacking plate 2a is spaced apart from the bottom surface of the leveling mechanism 4. When the lifting plate 2a of the mechanism 2 is at the highest position, the lifting plate 2a is against the bottom surface of the leveling mechanism 4 . When the leveling device is in use, the precision instrument a is installed on the leveling mechanism 4. When the leveling device is in the shock-absorbing state, the jacking plate 2a of the jacking mechanism 2 is arranged at intervals from the bottom surface of the leveling mechanism 4. , the damping mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com