Automobile accessory cutting and chamfering device

A technology for auto parts and chamfering devices, which is applied in other manufacturing equipment/tools, metal processing, manufacturing tools, etc., and can solve the problems of low processing efficiency and a large number of manual participation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

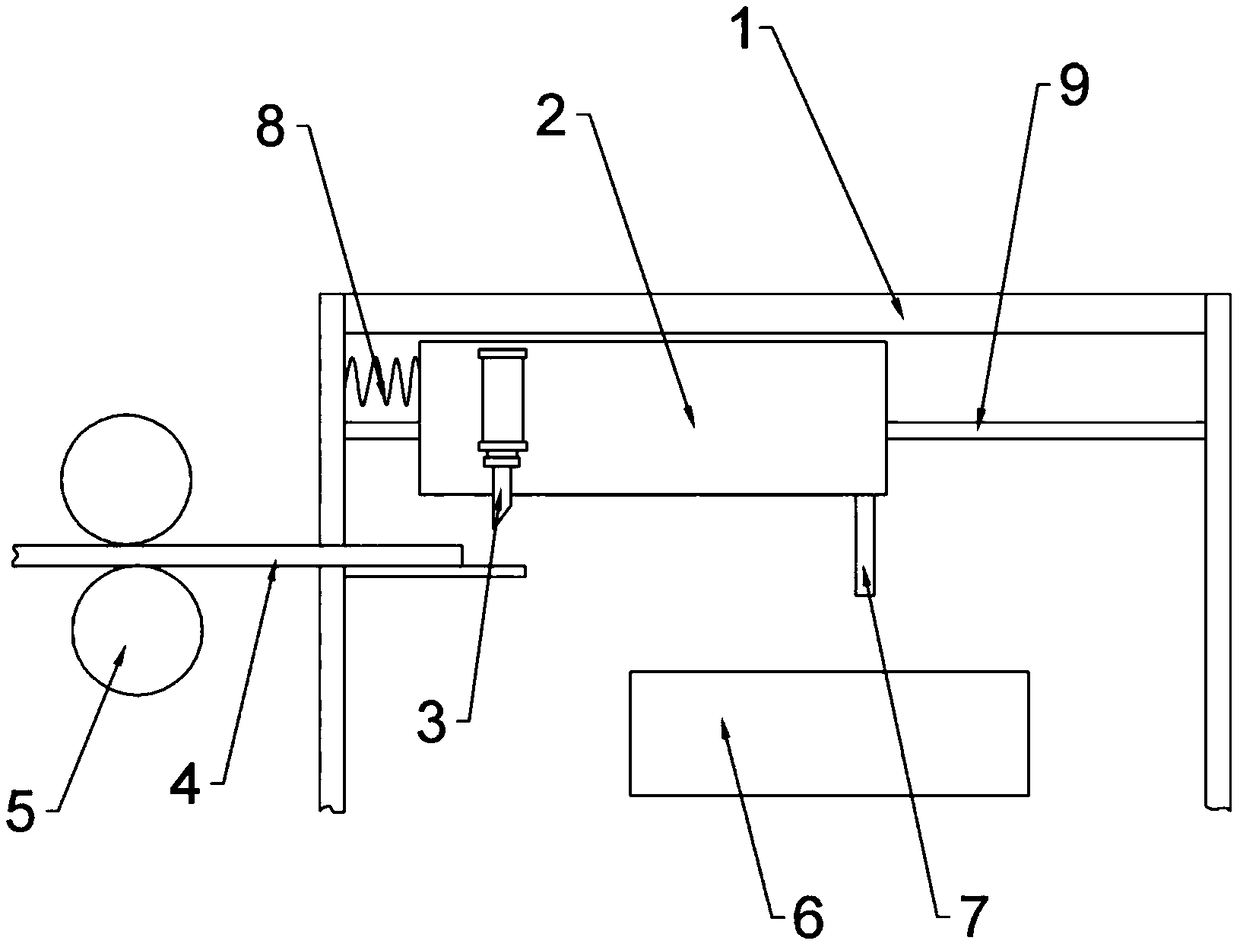

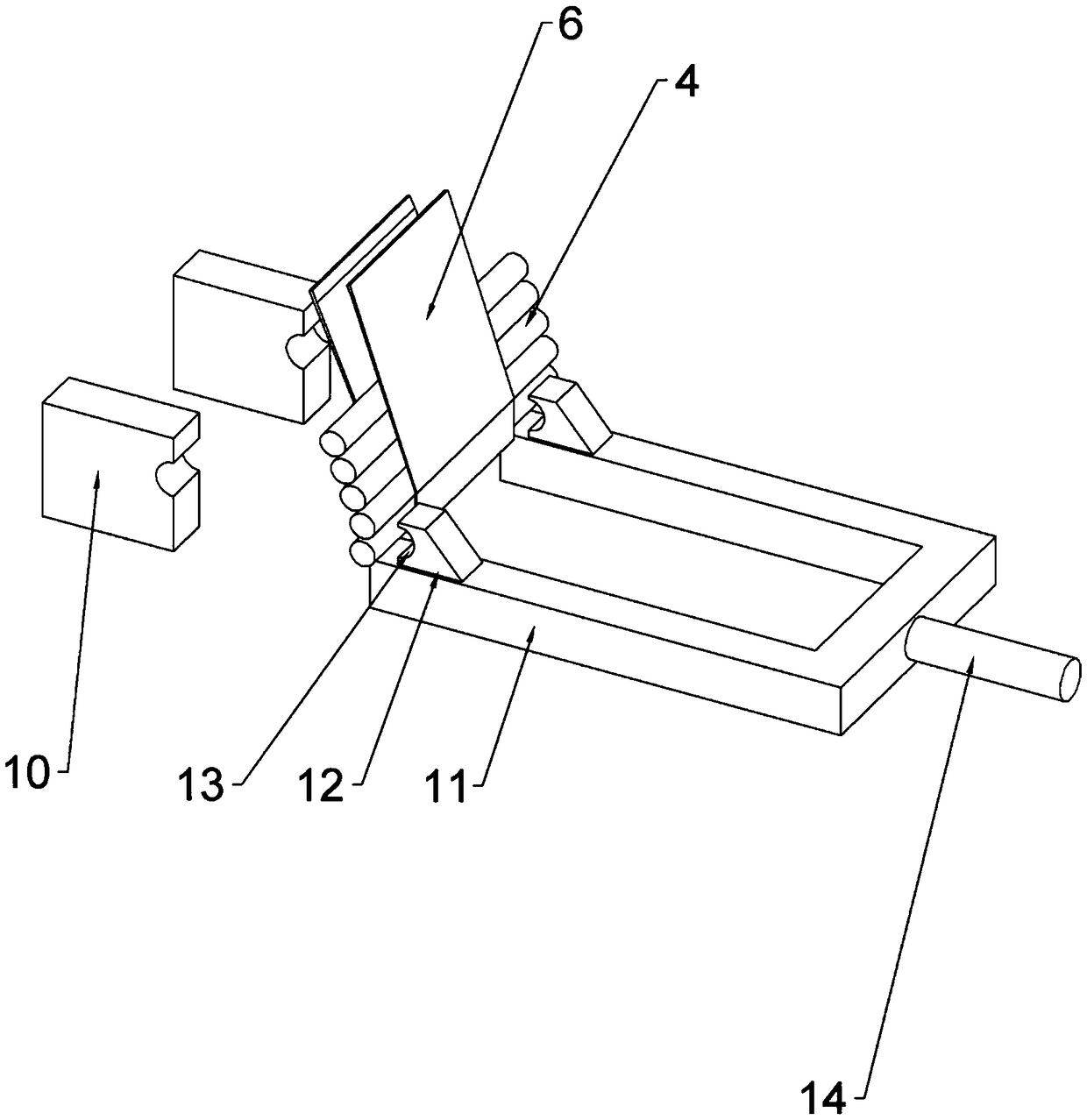

[0019] This embodiment is basically as attached figure 1 and figure 2 Shown: a cutting and chamfering device for auto parts 4, including a frame 1 and a torsion spring. One end of the frame 1 is provided with a feeding mechanism, and the feeding mechanism in this embodiment is two feeding rollers 5. A cutting mechanism is provided on the frame 1, and a blanking channel 6 is provided below the cutting mechanism, and a discharge port that only allows a single auto part 4 to pass is provided below the cutting device. A baffle is hinged at the discharge port, and the baffle passes through The torsion spring is connected with the blanking channel, and there is a clamping mechanism under the blanking channel. The clamping mechanism includes a fixed clamping plate 10 and a sliding clamping plate 11. The sliding clamping plate 11 is slidably connected with the frame 1, and the fixed clamping plate Cooperating with the sliding clamping plate 11, the auto parts 4 can be clamped. The s...

Embodiment 2

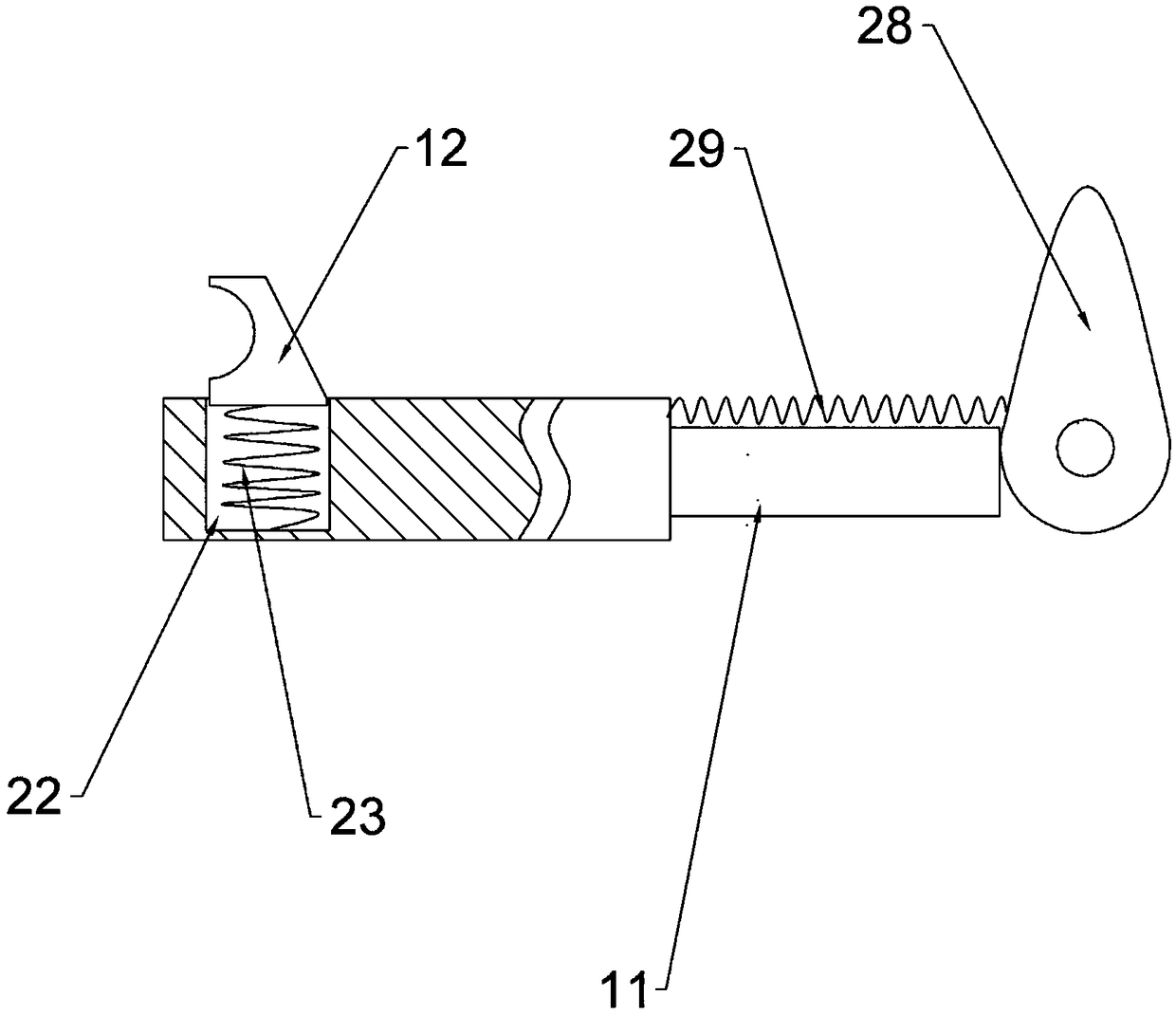

[0023] like image 3 , Figure 4 and Figure 5As shown, the present embodiment also includes a motor and a rotating shaft 15, the motor is fixed on the frame 1, the motor output shaft is connected with the rotating shaft 15, the rotating shaft 15 is provided with a first cam 28 and a second cam 16, the first cam 28 and The second cam 16 does not coincide. An elastic telescopic rod 14 is arranged at the right end of the sliding clamping plate 11 , and the elastic telescopic rod 14 abuts against the first cam 28 . A first spring 29 is provided between the right end of the sliding clamping plate 11 and the frame 1 . The elastic coefficient of the first spring 29 is smaller than that of the elastic telescopic rod 14 . A rack 17 is slidably connected to the frame 1, and a gear 20 is rotatably connected to the frame 1. The gear 20 meshes with the rack 17, the cam offsets the rack 17, and a spring is arranged between the rack 17 and the frame 1. The gear 20 Coaxially is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com