A detection method of weld starting point based on structured light vision sensor

A technology of optical visual sensor and visual sensor, which is applied in the direction of instruments, welding equipment, measuring devices, etc., can solve the problems of low positioning accuracy of fixtures, position deviation of welding seam starting point, inconsistent shape and size of workpieces to be welded, etc. The effect of inaccurate positioning, satisfying precision, and improving rapidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

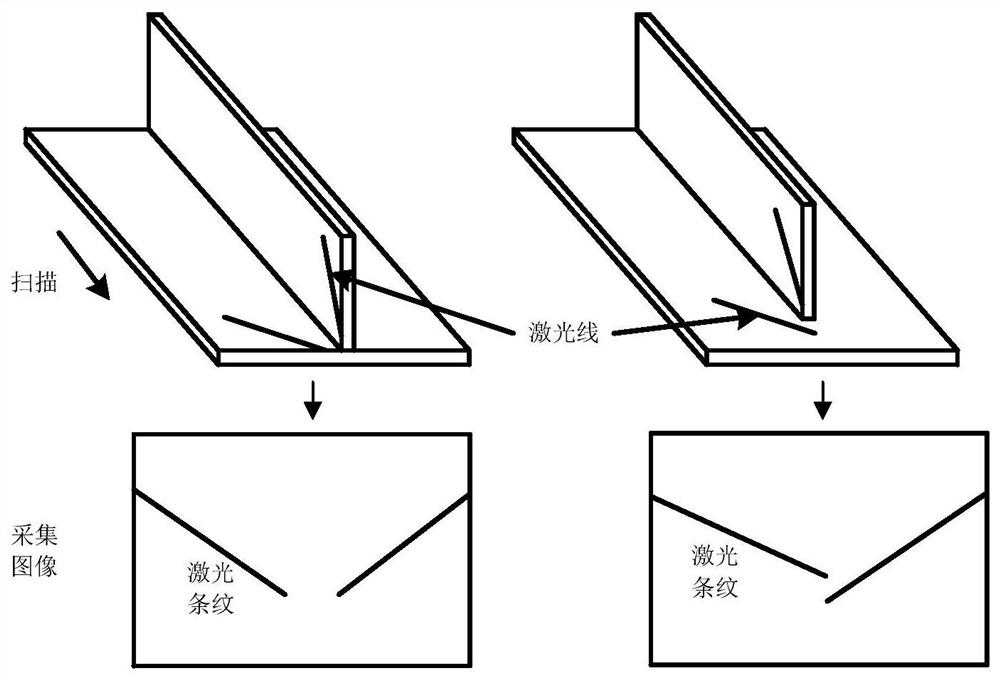

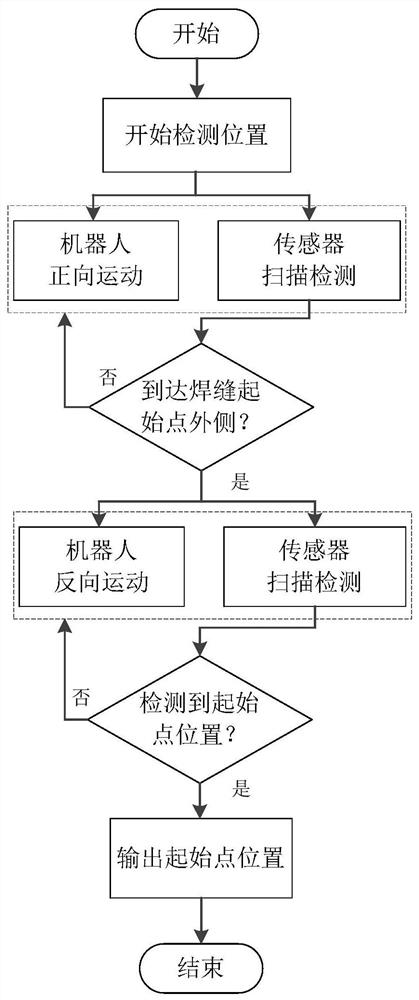

[0048] The starting point of the weld deviates from the ideal position when the workpiece is welded due to manufacturing errors and positioning errors of the fixture. The present invention uses a structured light visual sensor to detect the starting point of the T-shaped fillet weld workpiece. Since the structured light visual sensor can only output one weld point position per frame of image, the detection of the starting point needs to use scanning detection. Way.

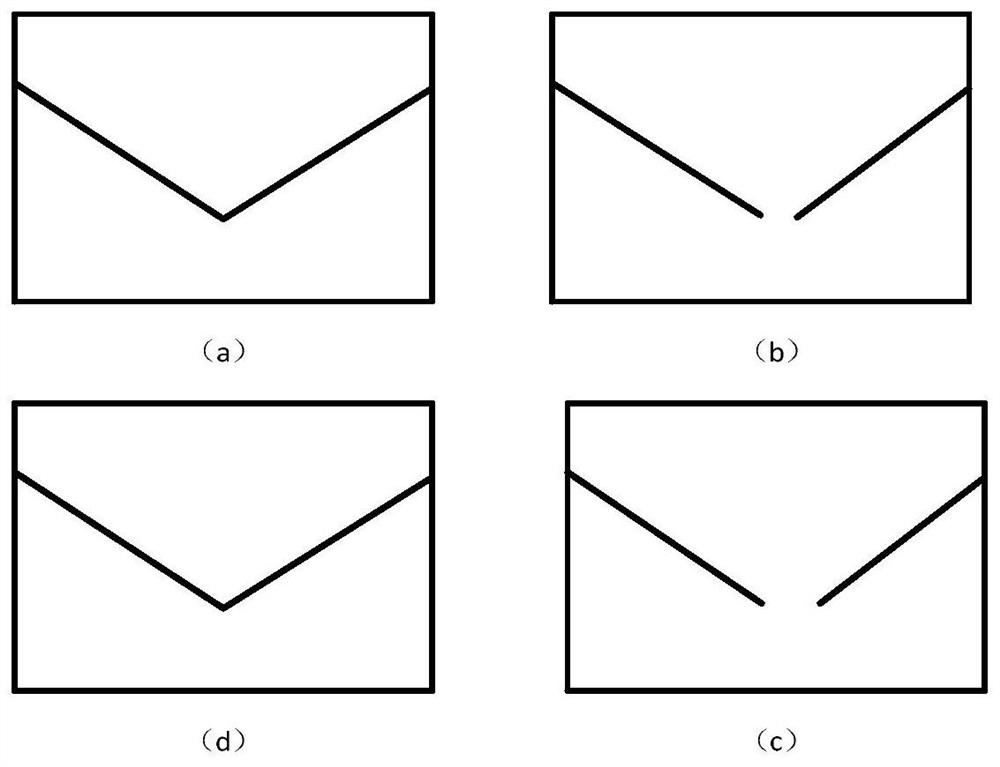

[0049] figure 1The figure shows the shape of the starting point of a typical T-shaped fillet weld. Due to its different structure, when the laser irradiates the area near the starting point of the weld, the shape of the laser stripes in the image is also different. figure 2 It is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com