Spraying mechanism for ceramic processing

A spraying mechanism and ceramic processing technology, which is applied in the direction of coating, spraying device, and device for coating liquid on the surface, etc., can solve the problems of insufficient spraying speed, limited effect, and increased manual labor, so as to save processing time, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

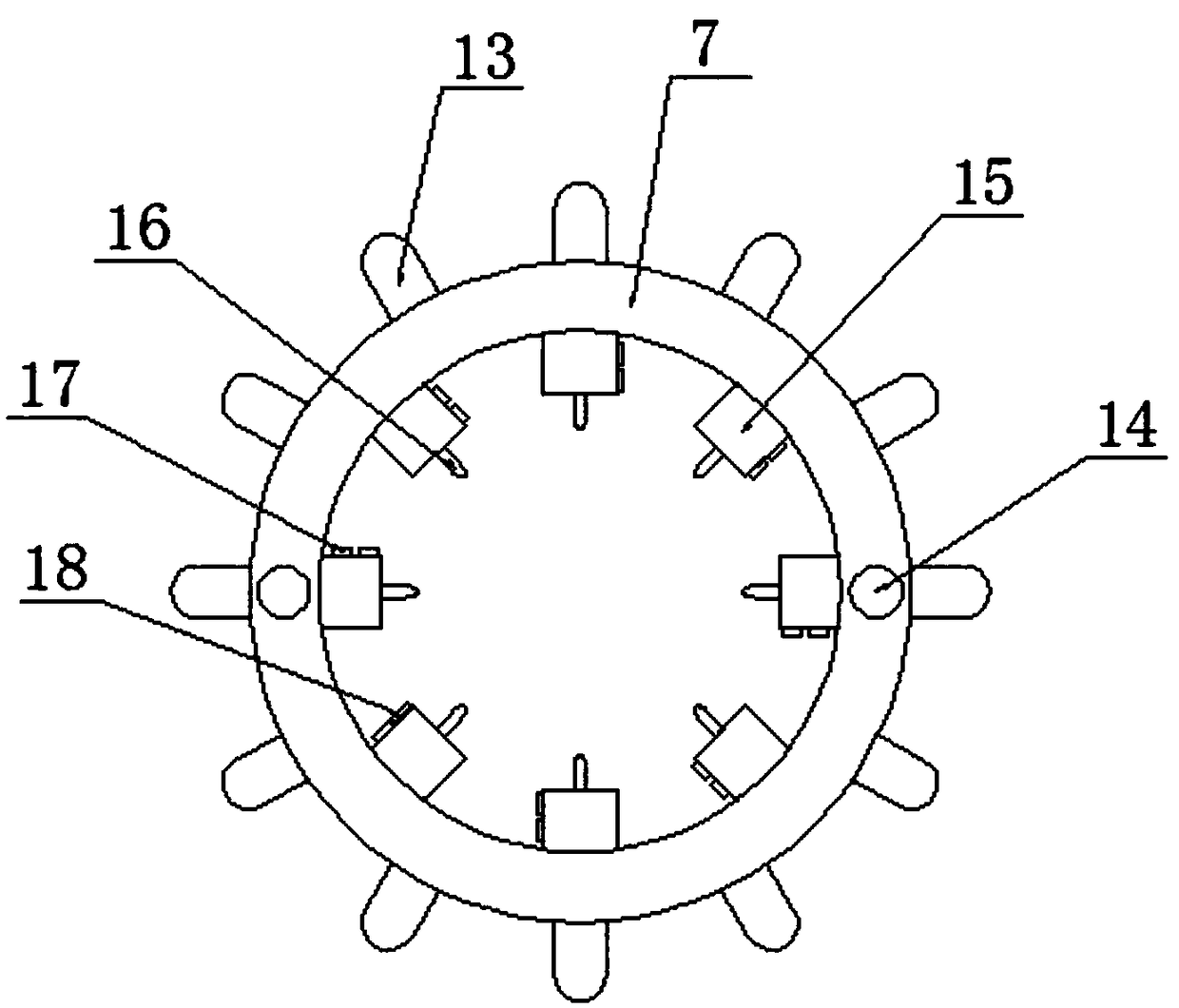

[0019] Example: such as Figure 1-4 As shown, a spraying mechanism for ceramic processing of the present invention includes a workbench 1, the four corners of the bottom surface of the workbench 1 are fixedly connected to the support legs 2, the four corners of the top surface of the workbench 1 are fixedly connected to the support column 3, and the top of the support column 3 is fixedly connected to The top plate 4, the center of the upper surface of the workbench 1 is fixed with a placement table 5, the lower surface of the top plate 4 is fixedly connected to the electric telescopic rod 6, and the bottom of the top plate 4 is provided with a horizontal fixing ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com