Pulverizer and mechanical tooth for waste treatment

A technology of mechanical teeth and pulverizers, applied in the field of mechanical teeth, can solve the problems of unreasonable combination, affecting work efficiency, damage to the structure of mechanical teeth and tooth heads, etc., and achieves good overall structure firmness, convenient use and installation, and improved work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

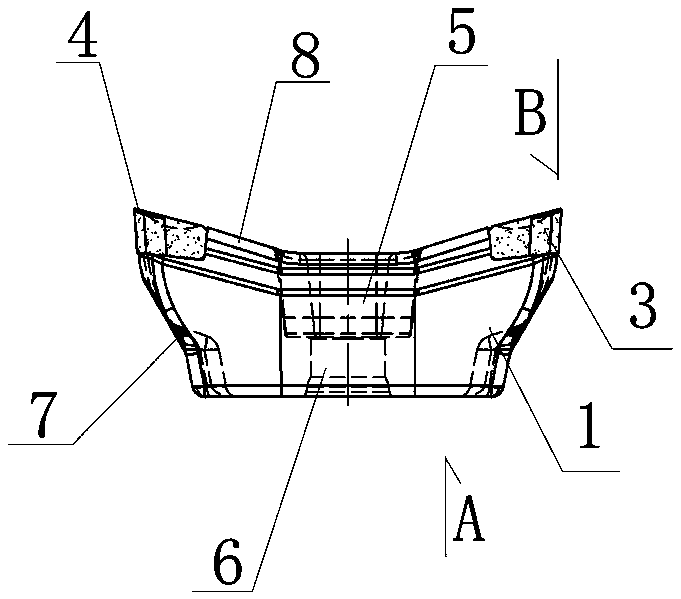

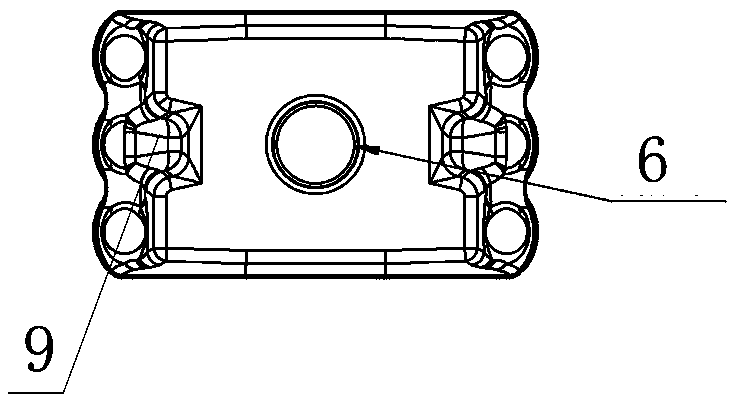

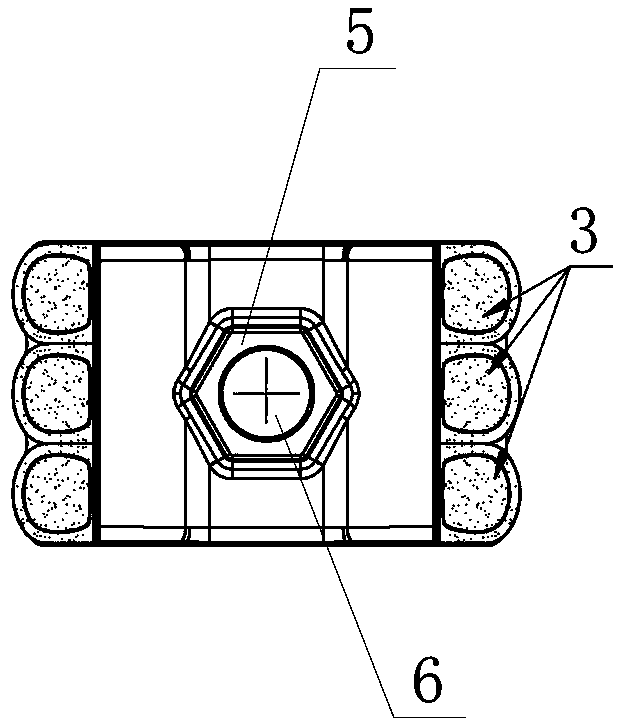

[0010] The present invention will be described in detail below in conjunction with accompanying drawing: Figure 1-3 As shown in the present invention, a pulverizer and a mechanical tooth for waste treatment include a one-piece briquetting body 1, and the upper two symmetrical sides of the briquetting body 1 are provided with downward strip-shaped concaves. The notch 2 is embedded and welded with at least three cemented carbide hooves 3 connected side by side, and the head end of the cemented carbide hoof 3 is formed with an outward and slightly upturned pointed tip 4. The upper middle position of the briquetting body 1 is provided with a hexagonal positioning single hole 5, and an assembly through hole 6 is provided in the middle of the hexagonal positioning single hole 5; the two symmetrical sides of the briquetting body 1, namely The outer surface of the tungsten carbide shoe 3 is provided with an obliquely downward and indented surface 7, which makes the briquetting body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com