Battery material crushing and iron removing device

A battery material and electromagnetic board technology, applied in magnetic separation, solid separation, grain processing, etc., can solve the problems of less raw materials, insufficient working effect of the adsorption device, and easy sticking to the inner wall of the equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

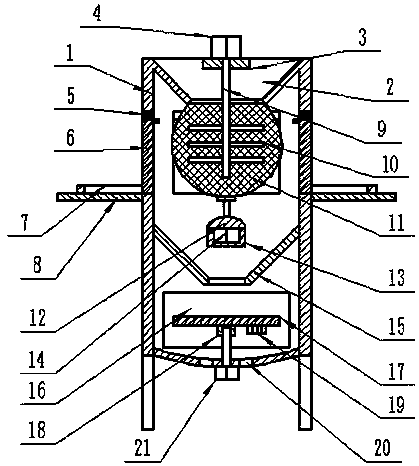

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

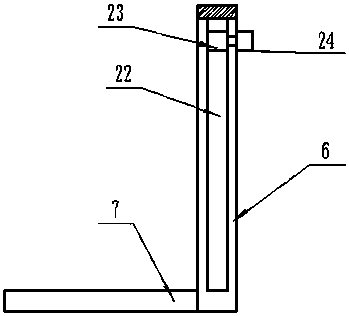

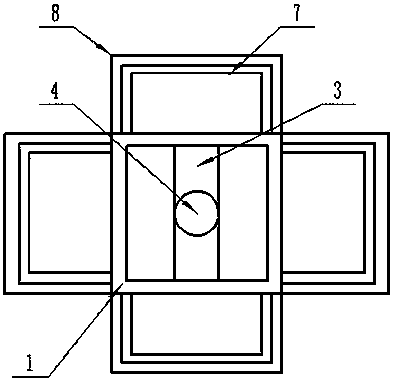

[0018] see Figure 1-3 , a battery material crushing iron removal device, including a box 1; the box 1 is provided with a funnel feed port 2, a first motor plate 12, a first motor 14, a mesh body 11, a motor cover 13, a second Motor plate 3, long shaft 9, second motor 4, crushing rod 10, conductive copper sheet 5, first electromagnetic plate 6, drawing frame 7, support plate 8, slideway 22, slider 23, scraper 24, transition funnel Tube 15, third motor 21, second electromagnetic plate 17, power supply box 19, threaded tube 18, box door 16 and annular mouth 20; Described funnel feeding port 2 is arranged on the upper end of casing 1 interior and funnel feeding port 2 port is at the upper end surface of the box body 1, and the funnel feed port 2 is used to put in battery materials; the first motor plate 12 is set at the middle position inside the box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com