Industrial production method of intestinal tract probiotic preparation

A technology of intestinal probiotics and probiotics, applied in the direction of microorganism-based methods, biochemical equipment and methods, bacteria, etc., can solve the problems of low number of viable bacteria in probiotic preparations, death of bacteria, and reduction of the overall vitality of bacteria , to improve the body's immunity, protect the activity, and maintain the balance of intestinal flora

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

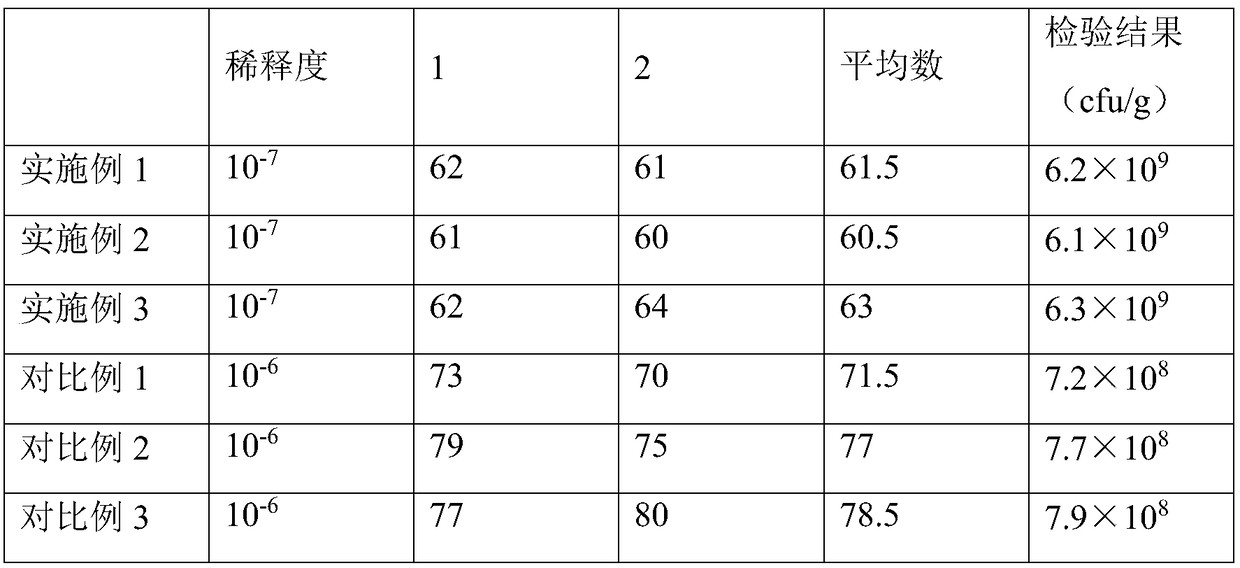

Examples

Embodiment 1

[0031] 1. Fermentation and cultivation of Lactobacillus casei, Lactobacillus rhamnosus, Bifidobacterium bifidum, Lactobacillus acidophilus, Streptococcus thermophilus, Lactobacillus delbrueckii subsp. Add 2% agar in the base, cultivate for 24 hours, then insert in the Erlenmeyer flask liquid culture medium (the culture medium formula is the same as that of the large tank culture medium) and cultivate separately, cultivate for 24 hours at 37°C, and then expand the cultivation step by step, and then Then carry out fermentation and culture in large tanks separately, culture at 37°C, and stir properly during the culture process; after 24 hours of culture, detect the total number of probiotics in the fermentation liquid, when the number of bacteria in the fermentation liquid reaches 1.5×10 9 cfu / mL, end the culture;

[0032] The formula of the large tank medium is: soybean peptide 2.0g, whey powder 5.0g, glucose 10.0g, lactose 2.0g, trypsin hydrolyzed casein 5.0g, beef extract 2.0g...

Embodiment 2

[0038] 1. Fermentation and cultivation of Lactobacillus casei, Lactobacillus rhamnosus, Bifidobacterium bifidum, Lactobacillus acidophilus, Streptococcus thermophilus, Lactobacillus delbrueckii subsp. Add 2% agar in the base, cultivate for 20 hours, then insert in the Erlenmeyer flask liquid culture medium (the culture medium formula is the same as the large tank culture medium) and cultivate respectively, cultivate for 20 hours at 37°C, then expand and cultivate step by step, and then Then carry out fermentation and culture in large tanks separately, culture at 37°C, and stir properly during the culture process; after 24 hours of culture, detect the total number of probiotics in the fermentation liquid, when the number of bacteria in the fermentation liquid reaches 2.0×10 9 cfu / mL, end the culture;

[0039] The formula of the large tank medium is: soybean peptide 3.0g, whey powder 4.0g, glucose 15.0g, lactose 2.5g, trypsin hydrolyzed casein 5.0g, beef extract 5.0g, yeast extr...

Embodiment 3

[0045] 1. Fermentation and cultivation of Lactobacillus casei, Lactobacillus rhamnosus, Bifidobacterium bifidum, Lactobacillus acidophilus, Streptococcus thermophilus, Lactobacillus delbrueckii subsp. Add 2% agar in the base, cultivate for 24 hours, then insert in the Erlenmeyer flask liquid culture medium (the culture medium formula is the same as that of the large tank culture medium) and cultivate separately, cultivate for 24 hours at 37°C, and then expand the cultivation step by step, and then Then carry out fermentation and culture in large tanks respectively, static culture at 37°C, and stir properly during the culture process; after 24 hours of culture, detect the total number of probiotics in the fermentation liquid, when the number of bacteria in the fermentation liquid reaches 2.5×10 9 cfu / mL, end the culture;

[0046] The formula of the large tank medium is: soybean peptide 5.0g, whey powder 1.0g, glucose 5.0g, lactose 6.0g, trypsin hydrolyzed casein 10g, beef extra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com