A temperature compensating device used for a real-time low-temperature split Hopkinson pressure bar test

A technology of Hopkinson pressure bar and temperature compensation device, which is applied in the direction of using a single impact force to test the strength of materials, measuring devices, analyzing materials, etc., can solve problems such as difficulties in material testing and research, achieve obvious economic benefits, prevent safety accidents, The effect of security assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail through the embodiments below in conjunction with the accompanying drawings.

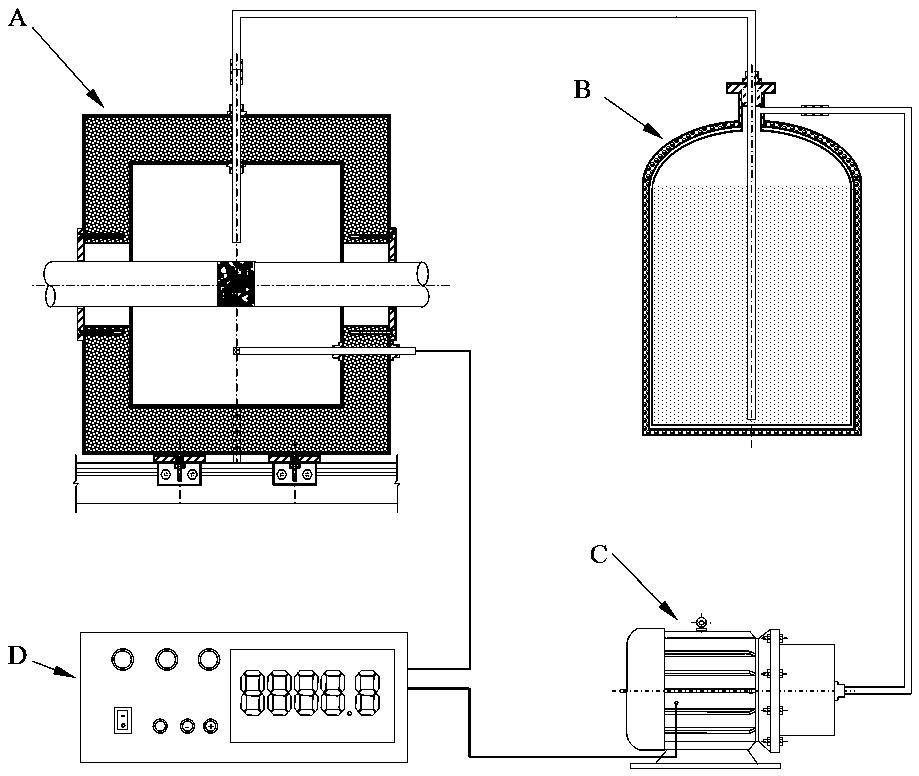

[0033] see figure 1 , the temperature compensation device for real-time low-temperature separated Hopkinson pressure bar test includes a low-temperature environment box A, a low-temperature liquid nitrogen bottle B, an air pump C and a temperature controller D. Air pump C is a miniature vacuum pump, adjust the pressure regulating valve to the required pressure value and output gas stably.

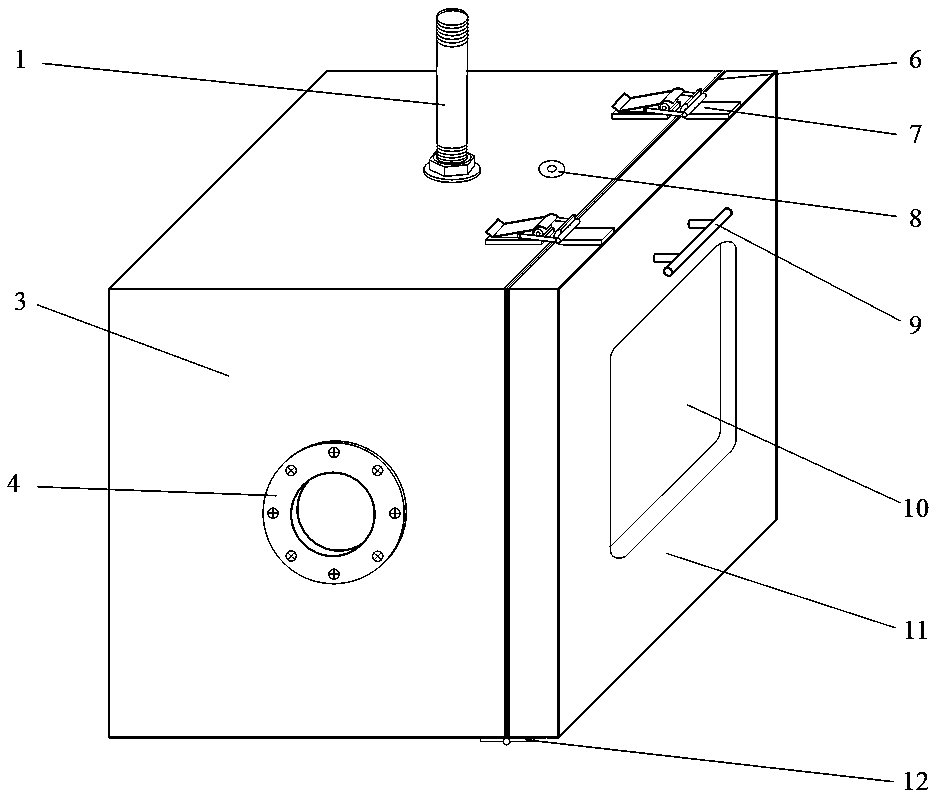

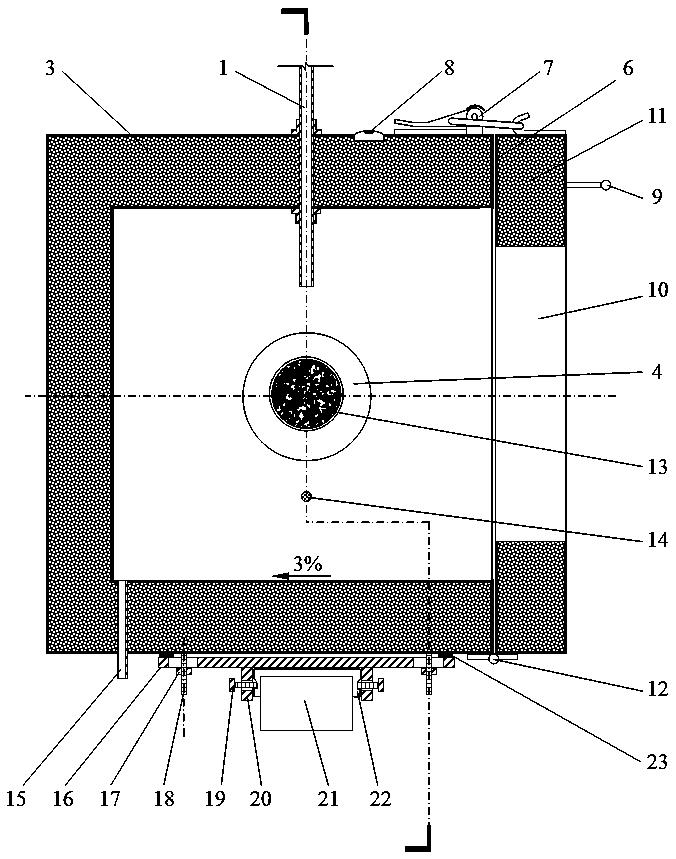

[0034] see figure 2 , the low-temperature environment box A includes a box body 3, one side of the box body 3 is hinged and installed with a door 11 that opens downwards, a sealing ring 6 is installed between the box body 3 and the box door 11, and the box body 3 and the box door 11. A hasp lock mechanism is installed at the corresponding opening. see image 3 , the top, bottom and three sides of the casing 3 are cladding walls, and thermal ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com