Teaching test table for indoor automobile vibration and noise test

A technology for noise testing and teaching testing, applied in wheel testing, vehicle testing, machine/structural component testing, etc. It can solve the problems of inability to provide teaching platforms for students and related practitioners, long cycle times for testers, and many resources used. , to achieve the effect of good demonstration and tutoring, low cost of demonstration and teaching, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable researchers in the field to further understand the present invention and related technical contents, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

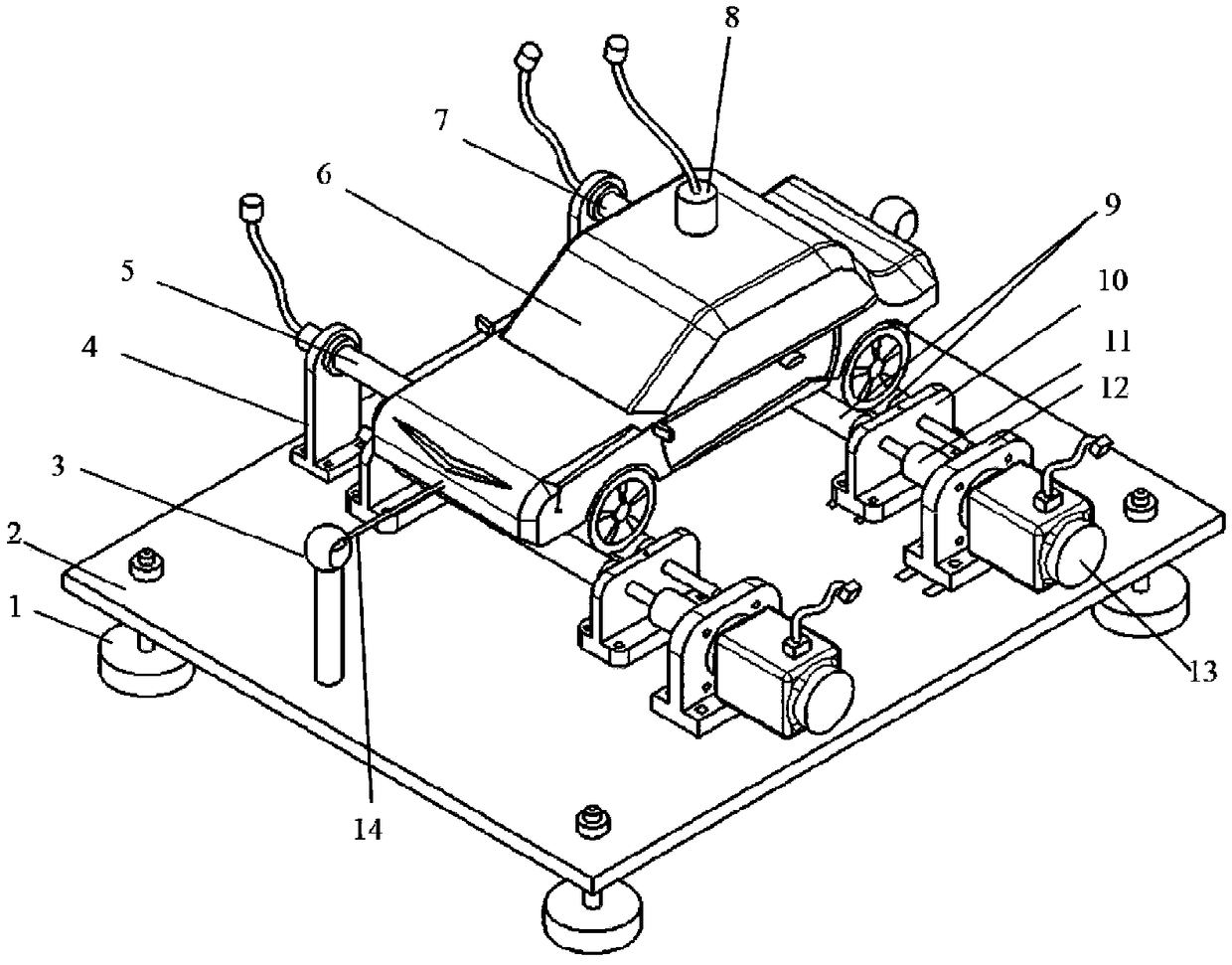

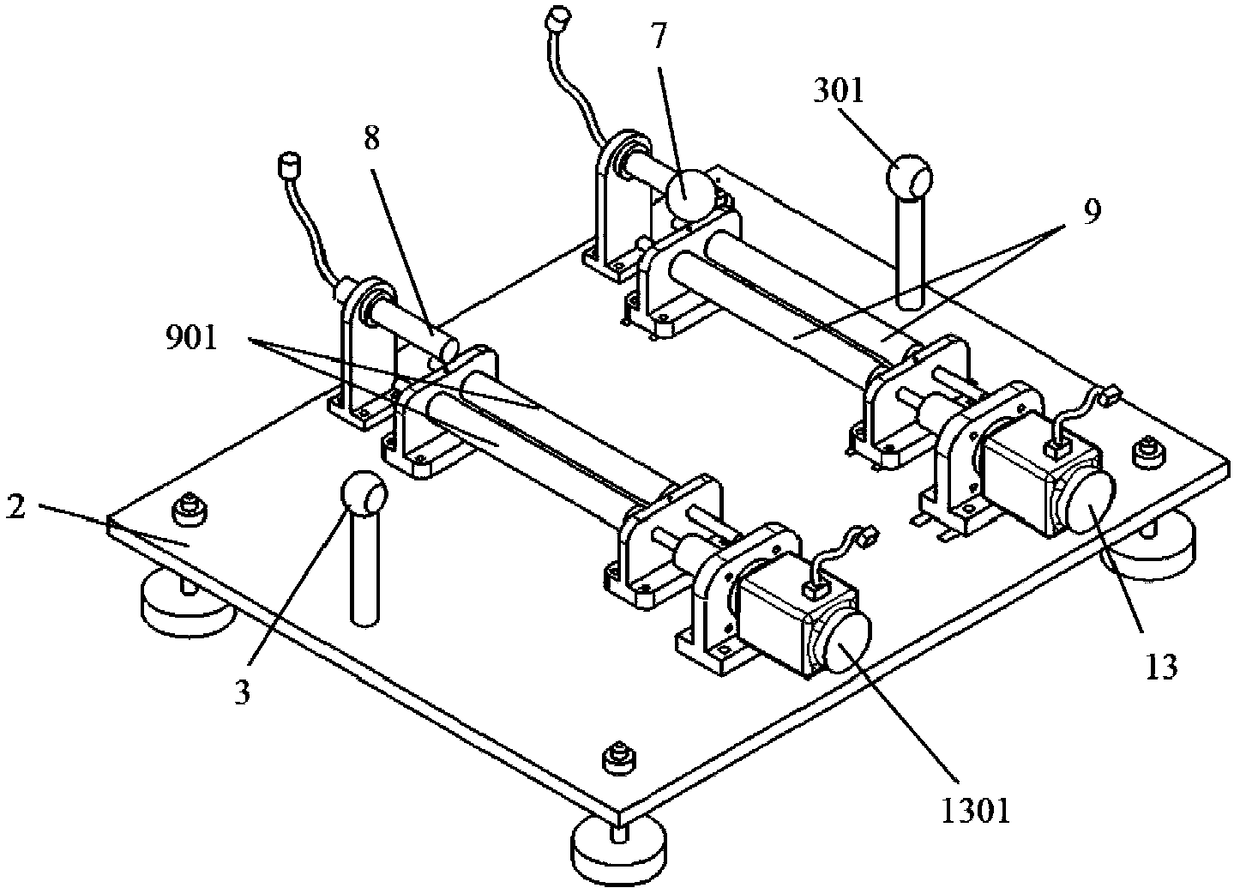

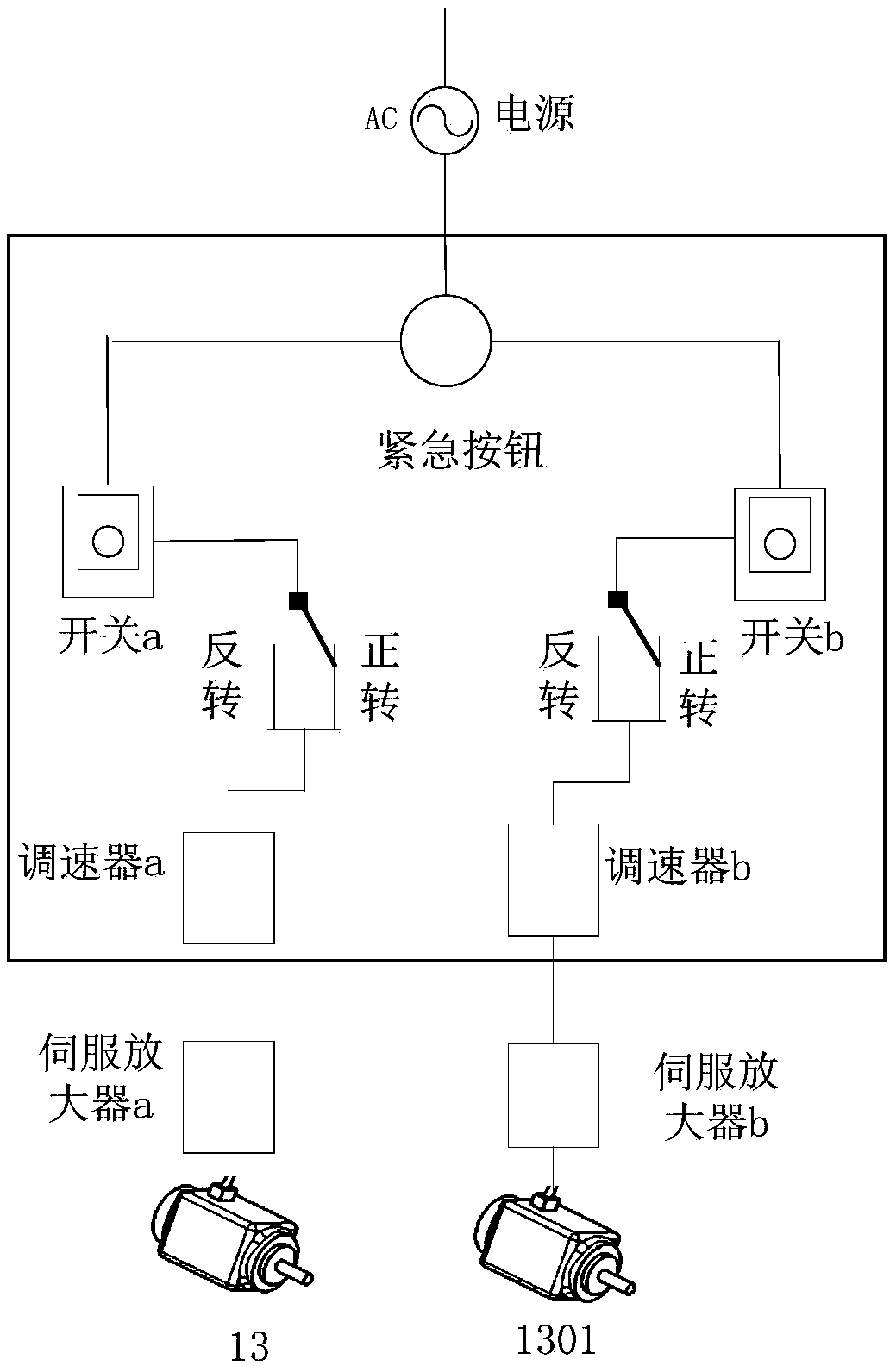

[0031] Such as figure 1 with figure 2 As shown, an indoor vehicle vibration and noise test teaching test bench includes: a base, two hub mechanisms, a control module, an acceleration sensor 8, a sound pressure sensor device and a rotational speed sensor device.

[0032] The base includes a mounting base plate 2, a number of shock-absorbing braces 1 evenly arranged on the bottom of the mounting base plate 2, and several vibration-damping feet 1 are arranged on the mounting base plate 2 for installing the hub mechanism, the sound pressure sensor device and the rotational speed. Long grooves for the sensor unit;

[0033] Two rotating hub mechanisms are arranged in parallel on the base to support the front and rear wheels of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com