High-precision differential type diaphragm optical fiber pressure sensing system

A technology of sensing system and pressure sensor, which is applied in the direction of measurement, measuring force, and measuring device by measuring the change of optical properties of the material when it is stressed, can solve the problem of not being able to directly obtain the direct force between surgical instruments and soft tissues, micro It solves the problems of lack of force sense information for surgeons, increases the probability of surgical uncertainty and risk factor, and achieves the effects of easy and precise operation, good insulation, and improved force sense resolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, the present invention will be further described.

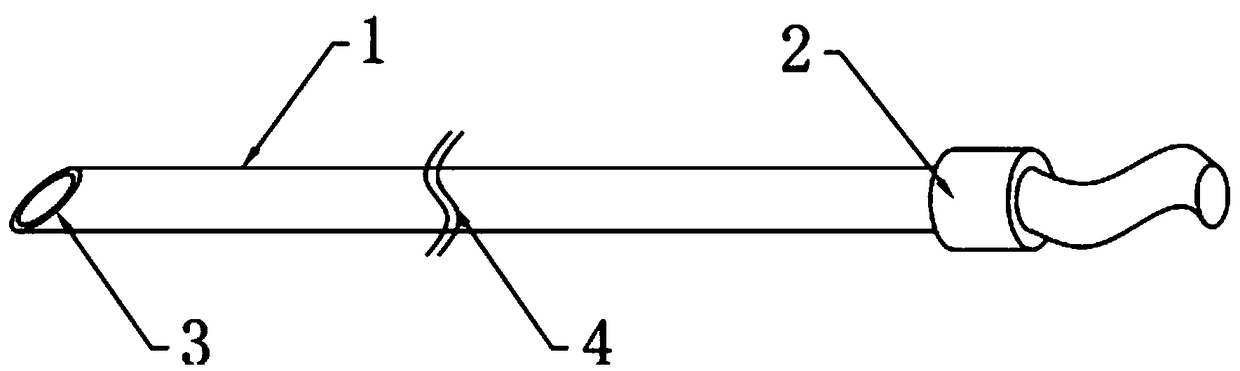

[0027] A high-precision differential diaphragm optical fiber pressure sensing system involved in the present invention is installed in a hollow minimally invasive surgical instrument, and puncture needles are commonly used instruments in minimally invasive surgery. The present invention uses puncture needles as Install objects such as figure 1 As shown, the front end of the puncture needle 1 is a needle tip 3 for piercing human soft tissue 4, and the end is an outer holding part 2 for connecting with external instruments. The puncture needle 1 is hollow, including a peripheral needle shell 101 and a hollow needle. cavity 102 .

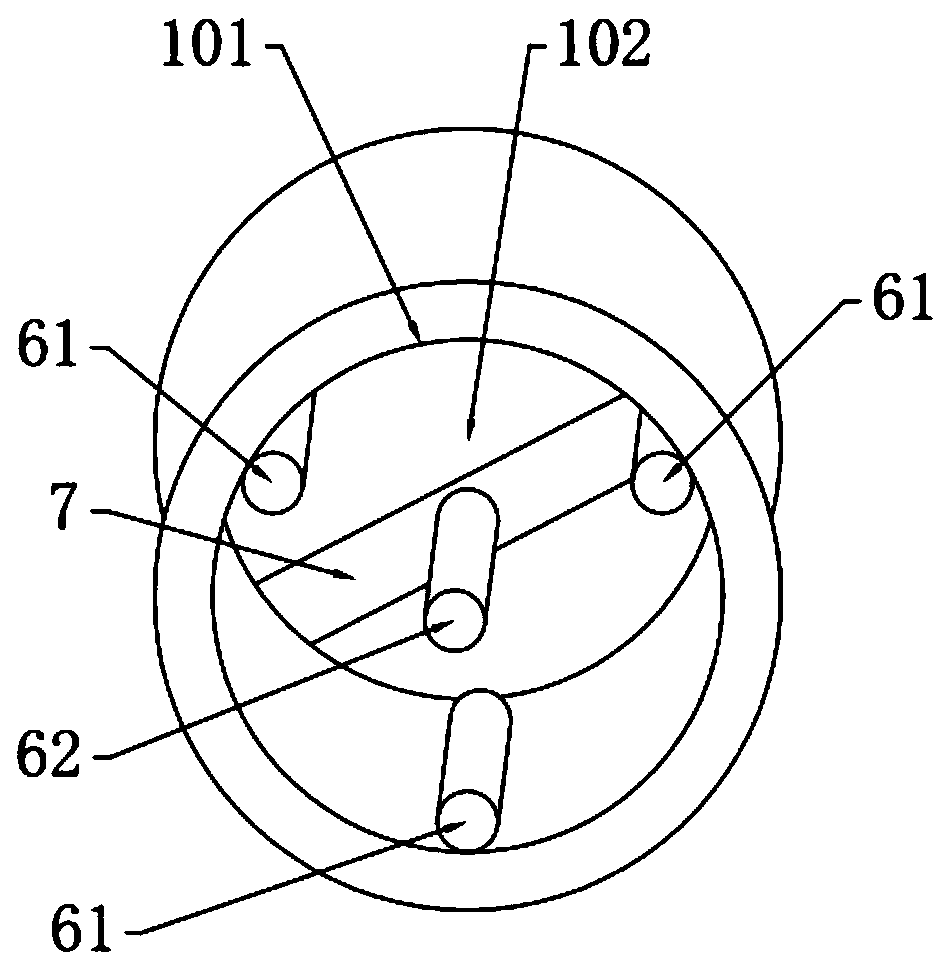

[0028] Such as figure 2 with image 3 As shown, the present invention relates to a high-precision differential diaphragm optical fiber pressure sensing system, including the sensing probe 6 placed in the needle cavity 102 of the puncture needle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com