Combined cooling and heating system for comprehensive utilization of clean energy and production waste heat

A clean energy, combined cooling and heating technology, applied in the field of heating and cooling, can solve the problems of continuous and stable operation, high investment cost and high operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

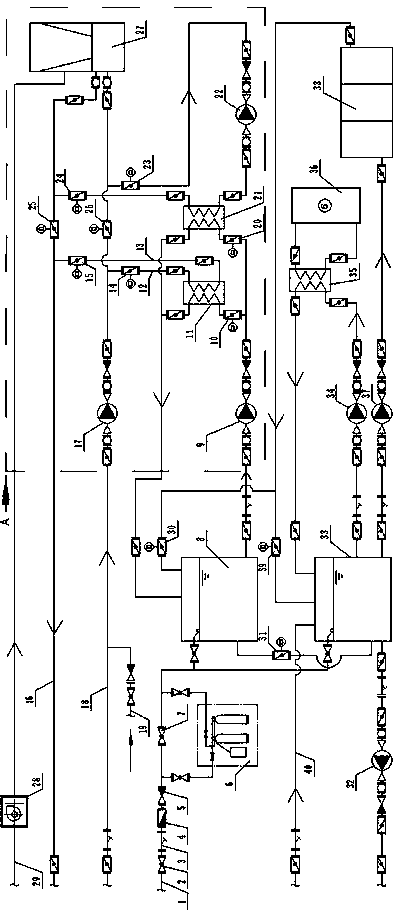

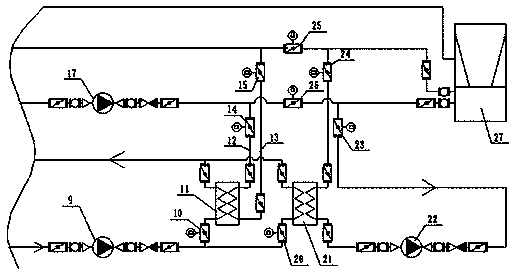

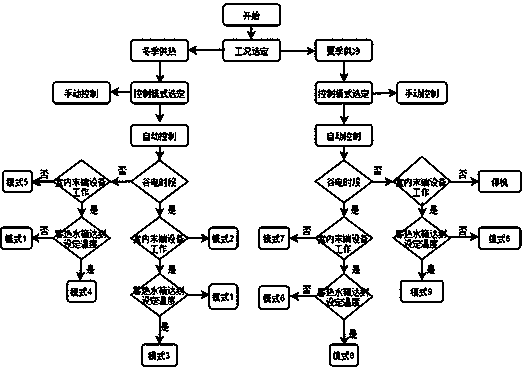

Method used

Image

Examples

Embodiment 2

[0057] Winter mode 2: Heat storage. In this mode, the air source heat pump 27 stores heat for the heating system, the air source heat pump 27 and the fan 28 are turned on, and the electric butterfly valve 25 and the electric butterfly valve 26 are in In the closed state, the air source heat pump 27 does not directly supply heat to the heating system. The circulating water pump 17 of the heating and cooling system is in a low-speed operation state, and the heat storage, heat storage, cooling, and releasing heat pumps 9, electric butterfly valve N 10, electric butterfly valve A 14, and electric butterfly valve B 15 on the heating and cooling circulation pipeline In the open state, the heating system circulates at a low speed; the cold storage and heat storage pumps 22 on the heat storage system, as well as the electric butterfly valve C20, electric butterfly valve D23, and electric butterfly valve E24 are all in an open state, so that the heat of the air source heat pump 27 passe...

Embodiment 3

[0059] Winter mode 3: heat storage, heat release, and heat supply. In this mode, the heating system is in a state of heat storage and heat release for indoor terminal equipment, and the air source heat pump 27 and fan 28 are turned on. The electric butterfly valve 25 and the electric butterfly valve 26 are in a closed state, and the air source heat pump 27 does not directly supply heat to the heating system. The circulating water pump 17 of the heating and cooling system is in a normal speed state, and the heat storage, heat storage, cooling and releasing heat pumps 9, electric butterfly valve N 10, electric butterfly valve A 14, electric butterfly valve B 15 on the heating and cooling circulation pipeline In the open state, the heating system circulates normally to supply heat to the indoor terminal equipment. The cold storage and heat storage pumps 22 on the heat storage system, as well as the electric butterfly valve C20, electric butterfly valve D23, and electric butterfly...

Embodiment 4

[0061] Winter mode 4: heat release and heat supply. In this mode, the heating system stops heat storage and only releases heat to provide heat for indoor terminal equipment. The air source heat pump 27 and fan 28 are in a closed state, and the electric butterfly valve 25 and all The above-mentioned electric butterfly valve 26 is in the closed state, and the cold storage and heat storage pumps 22 on the heat storage system, as well as the electric butterfly valve C20, the electric butterfly valve D23, and the electric butterfly valve E24 are all in the closed state, and the heat storage is interrupted. The circulating water pump 17 of the heating and cooling system is in a normal speed state, and the heat storage, heat storage, cooling and releasing heat pumps 9, electric butterfly valve N 10, electric butterfly valve A 14, electric butterfly valve B 15 on the heating and cooling circulation pipeline In the open state, the heating system normally circulates to supply heat to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com