Throwing glass breaking ball

A glass-breaking and body-based technology, applied in life-saving equipment, building rescue, etc., can solve the problems of glass-breaking rescue personnel injury, equipment use, and inability to use large areas, and achieve the effects of reduced contact area, high efficiency, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

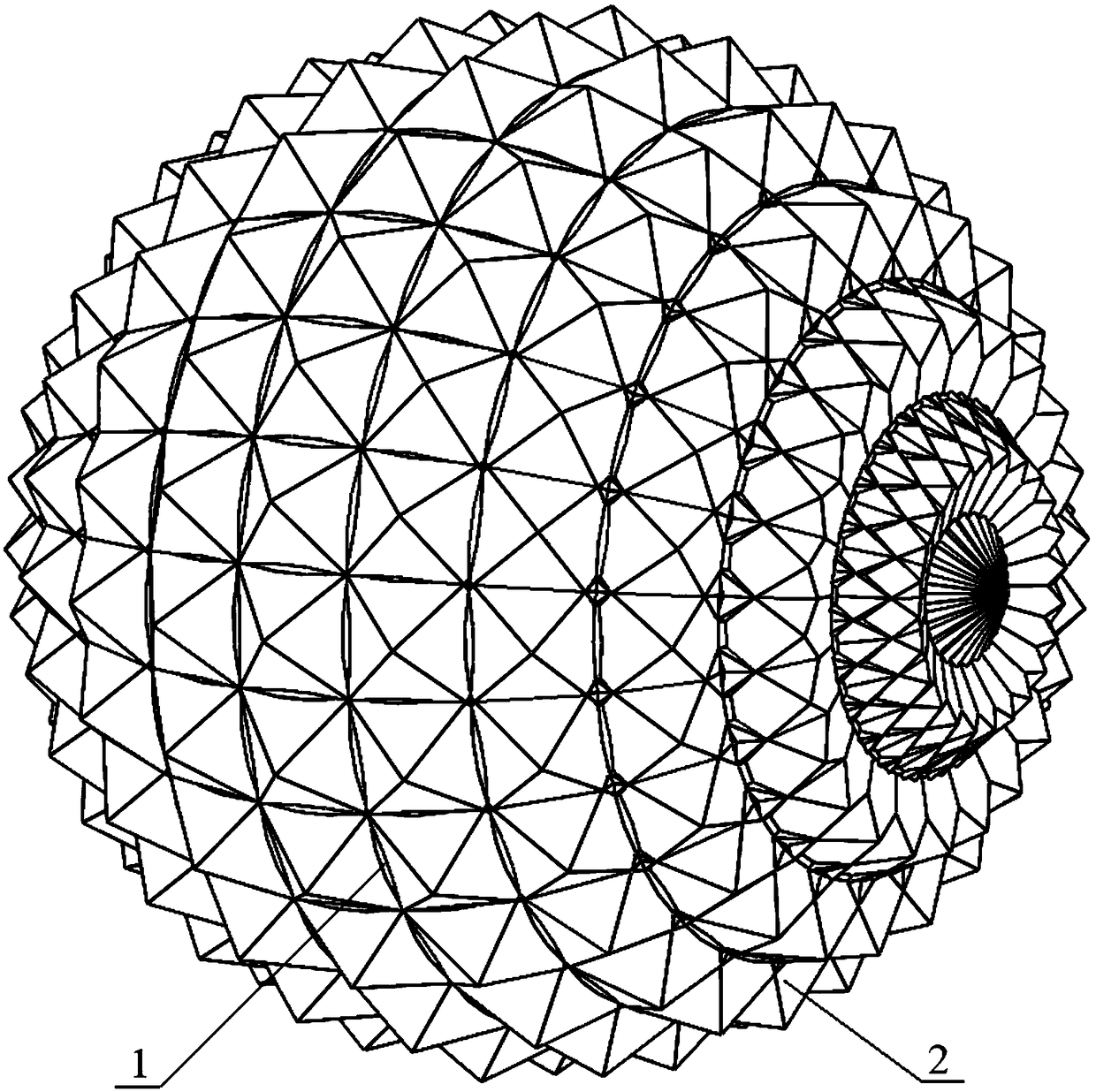

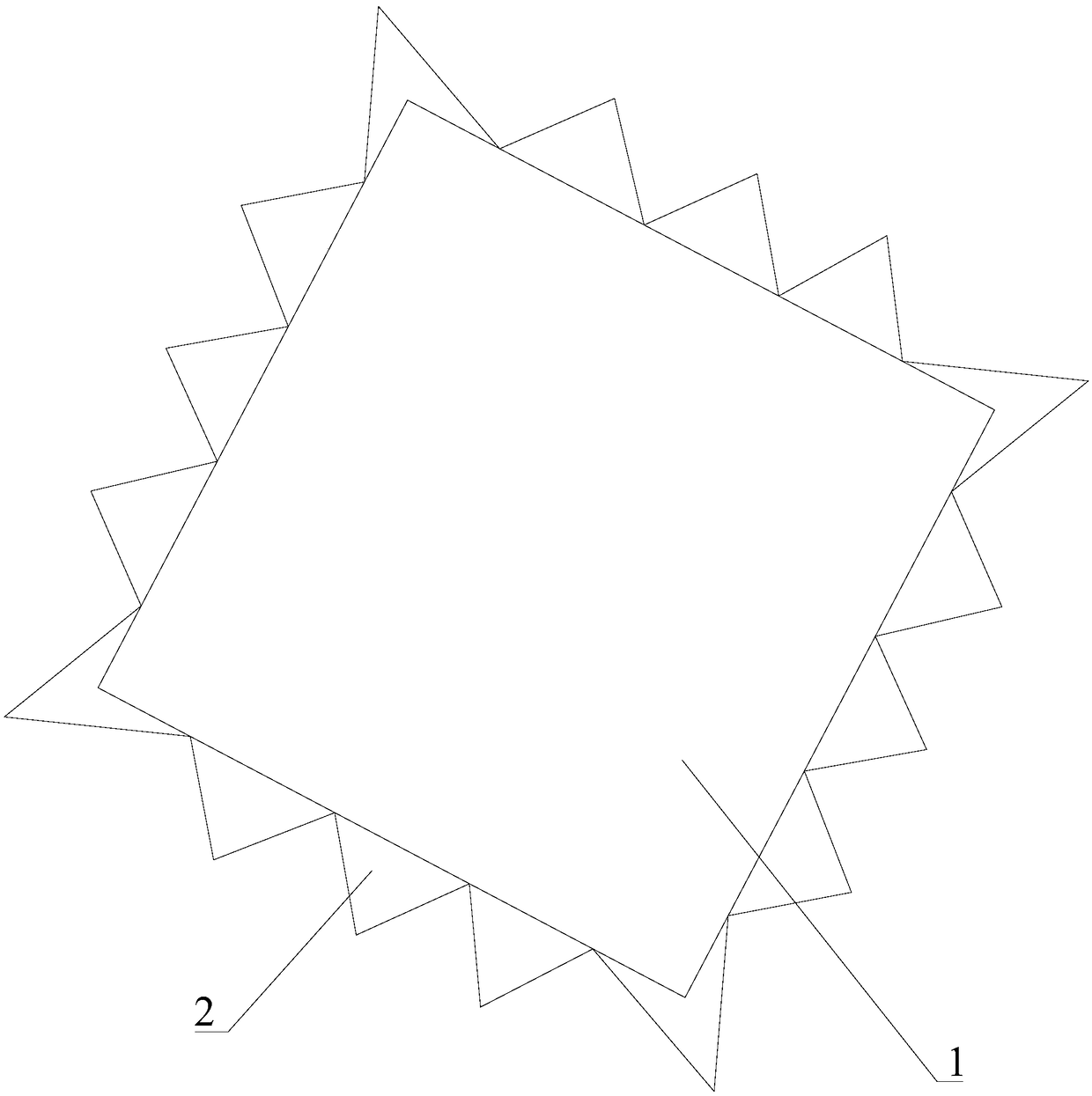

[0029] like Figure 1-Figure 2 As shown, a throwing glass-breaking ball includes a spherical body 1, and protrusions 2 uniformly distributed on the outer surface of the body 1, the hardness of the body 1 and the protrusions 2 are higher than that of tempered glass hardness.

[0030] figure 2 The protrusions 2 shown in are pyramid structures, all the protrusions 2 have the same size, and the cone angles θ of all the protrusions 2 are greater than or equal to 20 degrees and less than or equal to 160 degrees.

[0031] Preferably, the body 1 and the protrusion 2 have the same hardness, and the body 1 and the protrusion 2 are integrally formed structural parts.

[0032] Preferably, the protrusion 2 is a zirconia-toughened alumina ceramic (ZTA) structure, and the body 1 can also adopt this ceramic structure, wherein the addition ratio can be selected as 10%-30% zirconia and 70% -90% alumina. In actual production, the addition ratio is determined according to the performance of v...

Embodiment 2

[0034] like image 3 As shown, the difference between this embodiment and embodiment 1 is that the body 1 is a cuboid structure.

Embodiment 3

[0036] like Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the body 1 has a regular octagonal prism structure. On the surface of the body 1, there are a variety of protrusions 2 of different materials, different hardness and different sizes. By optimizing the design of the protrusions 2, a variety of glass breaking balls with different performances are formed to meet the actual glass breaking needs. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com