Ultrasonic mechanical linear scan probe with vibration-reduction function

A linear scanning and mechanical technology, applied in the field of scanning probes, can solve problems such as waste of resources, large vibration of ultrasonic probes, and image quality effects, and achieve the effect of reducing mechanical vibration and improving image quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] A vibration-reducing ultrasonic mechanical linear scanning probe of the present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings.

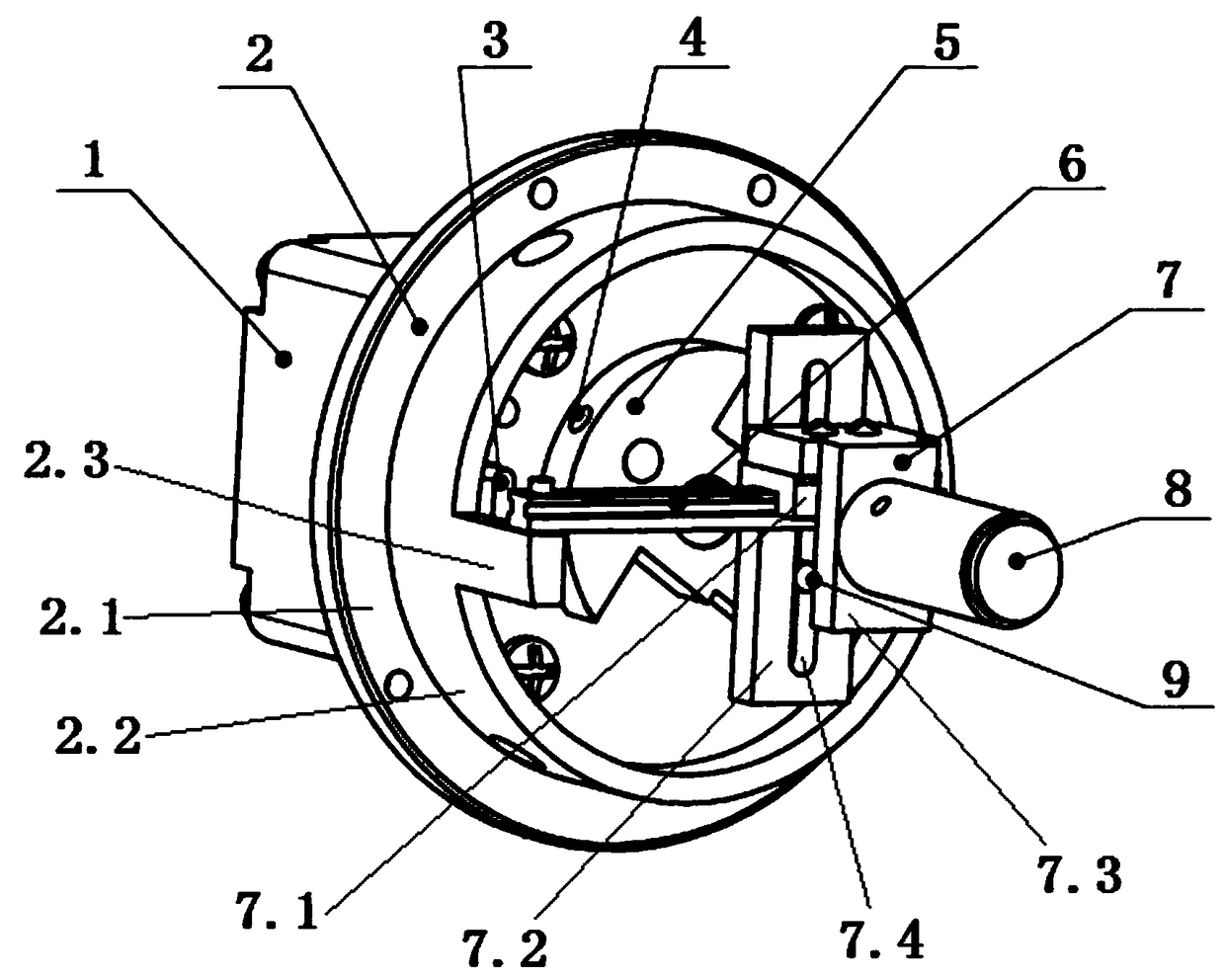

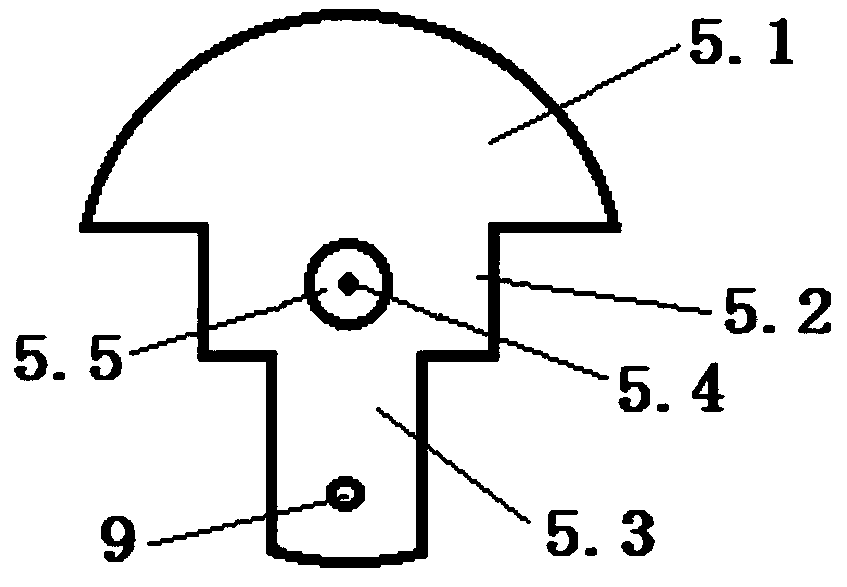

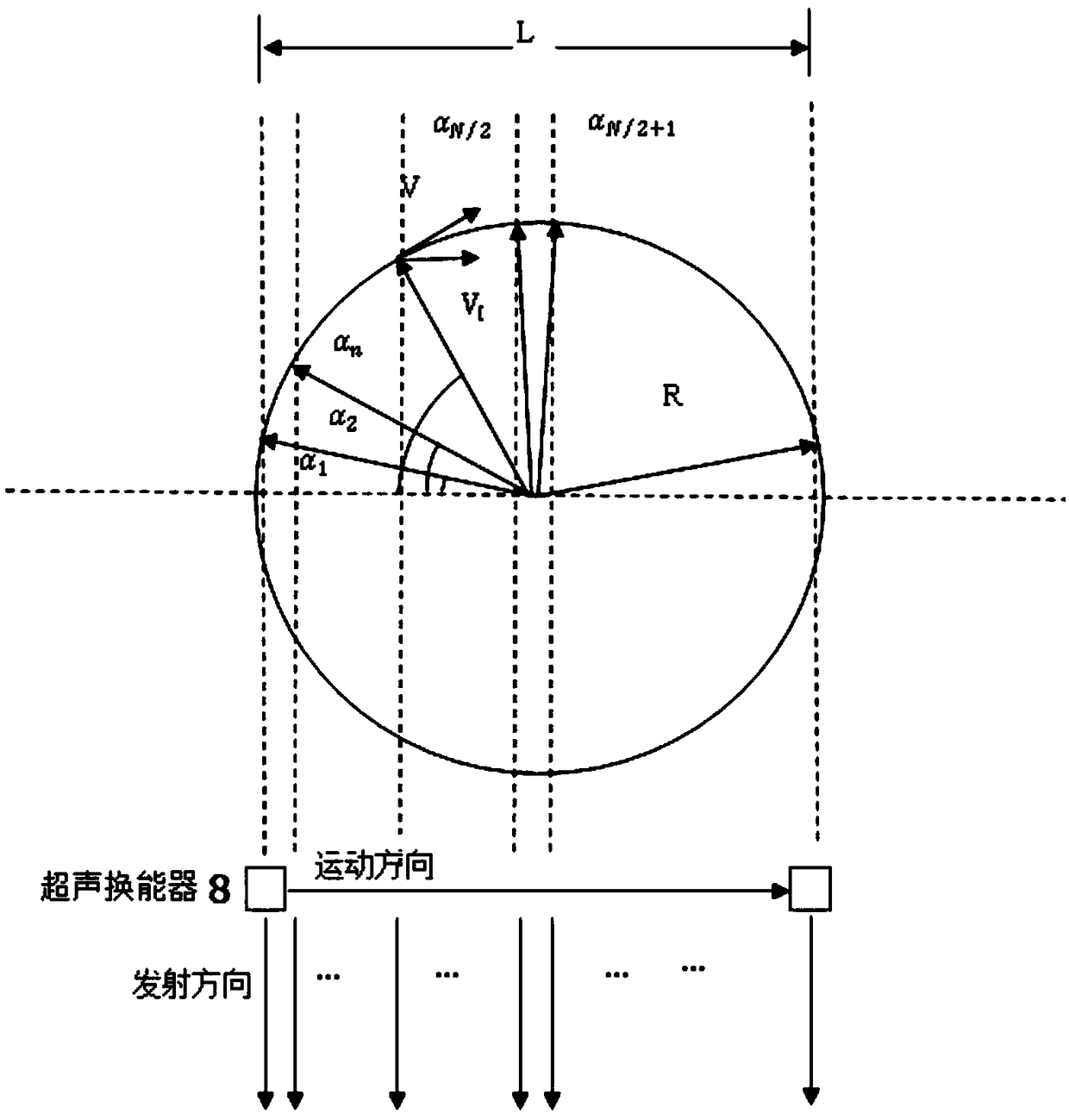

[0042] Such as figure 1 As shown, an ultrasonic mechanical linear scanning probe capable of reducing vibration of the present invention includes a stepper motor 1 and a probe main frame body 2, and the probe main frame body 2 is integrally connected to the chassis 2.1 by a chassis 2.1 The main body ring 2.2 constitutes that the diameter of the chassis 2.1 is larger than the diameter of the main body ring 2.2. The chassis 2.1 is fixedly connected to the front end surface of the stepper motor 1 by screws, the motor shaft of the stepper motor 1 runs through the chassis 2.1 and is fixedly connected to the eccentric wheel 5 located inside the main body ring 2.2, and the main body ring The front port of 2.2 is provided with a linear guide rail 6 horizontally along the diameter. A tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com