Preservative for dried Euphausia superb, and preparation method and application thereof

An Antarctic krill and preservative technology, applied in application, food drying, preservation of meat/fish with chemicals, etc., can solve the problems of brittleness and poor taste, achieve less loss of active ingredients, and solve the problem of dry and hard shrimp. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) prepare bamboo leaf extract: fresh bamboo leaf is placed in extraction tank, adding 8 times of the mass content of bamboo leaf quality is the ethanolic solution of 85%, regulating extraction tank pressure is 2.5MPa, after being warming up to 32 ℃, Extraction with the aid of ultrasonic waves with a frequency of 60KHz for at least 3h; filter the obtained extract to obtain a filtrate; place the filtrate in a vacuum concentration tank, and concentrate at 4°C until it becomes a paste to obtain a concentrated paste; Carry out low temperature drying, pulverize and pass through a 150 mesh sieve to obtain the bamboo leaf extract;

[0022] (2) Compounding: weighed according to the weight ratio of 4g calcium propionate, 4g natamycin, 12g bamboo leaf extract, 0.4g vitamin C, 4g sodium lactate, 0.7g sodium EDTA, 2g malic acid After each component, mix each component uniformly to obtain Antarctic krill dry preservative.

Embodiment 2

[0024] (1) prepare bamboo leaf extract: fresh bamboo leaf is placed in extraction tank, adding 7 times of the mass content of bamboo leaf quality is 80% ethanol solution, regulating extraction tank pressure is 2MPa, after being warming up to 30 ℃, with Ultrasonic-assisted extraction with a frequency of 50KHz for at least 3h; filter the obtained extract to obtain a filtrate; place the filtrate in a vacuum concentration tank, and concentrate at 3°C until it becomes a paste to obtain a concentrated paste; Dry at low temperature, pulverize and pass through a 150-mesh sieve to obtain the bamboo leaf extract;

[0025] (2) Compounding: weighed according to the weight ratio of 3g calcium propionate, 3g natamycin, 10g bamboo leaf extract, 0.3g vitamin C, 3g sodium lactate, 0.5g sodium EDTA, 1g malic acid After each component, mix each component uniformly to obtain Antarctic krill dry preservative.

Embodiment 3

[0027] (1) prepare bamboo leaf extract: fresh bamboo leaf is placed in extraction tank, adding 10 times of the mass content of bamboo leaf quality is 90% ethanol solution, regulating extraction tank pressure is 3MPa, after being warming up to 35 ℃, with Ultrasonic-assisted extraction with a frequency of 70KHz for at least 3h; filter the obtained extract to obtain a filtrate; place the filtrate in a vacuum concentration tank, and concentrate at 5°C until it becomes a paste to obtain a concentrated paste; Dry at low temperature, pulverize and pass through a 150-mesh sieve to obtain the bamboo leaf extract;

[0028] (2) Compounding: take by weighing the weight ratio of 5g calcium propionate, 5g natamycin, 15g bamboo leaf extract, 0.5g vitamin C, 5g sodium lactate, 1g sodium EDTA, 3g malic acid. After the components are combined, the components are mixed uniformly to obtain Antarctic krill dry preservative.

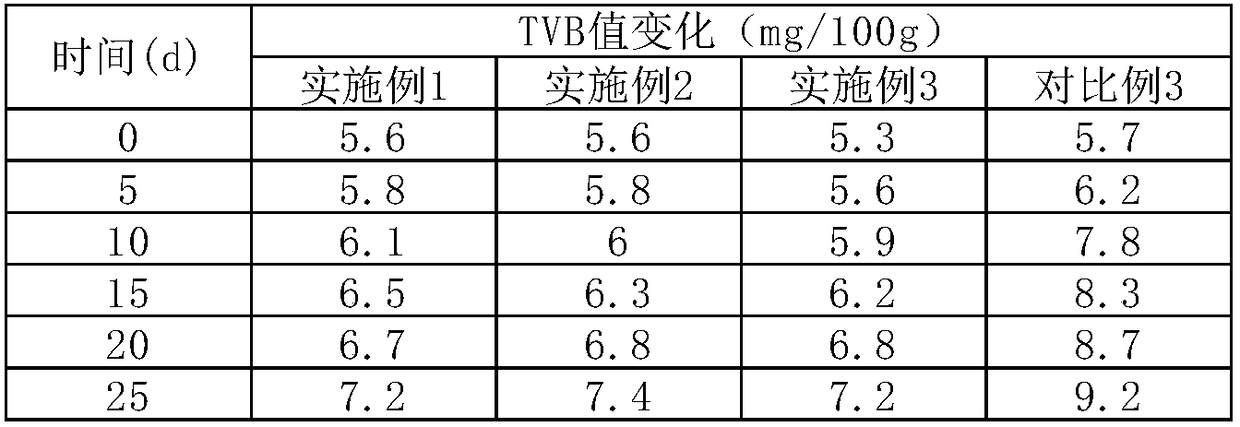

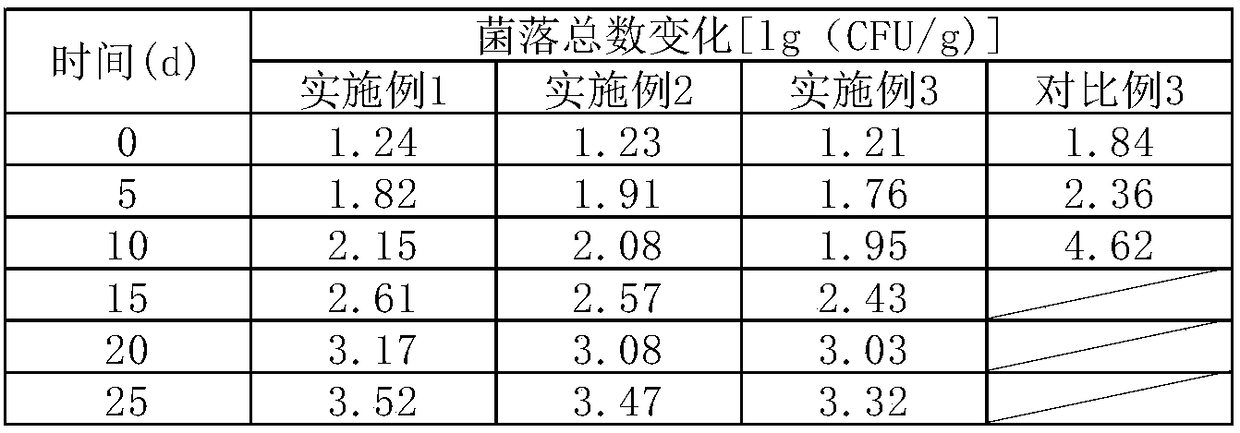

[0029]Take four parts of water with the same quality and divide them in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com