Pile mounting bracket and fuel cell using same

A technology for mounting brackets and fuel cells, which is applied to fuel cells, circuits, electrical components, etc., can solve the problems of complex structure, unreasonable structure settings, and single function of stack mounting brackets, and achieves easy handling and installation, simple structure, and reduced power consumption. the effect of interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

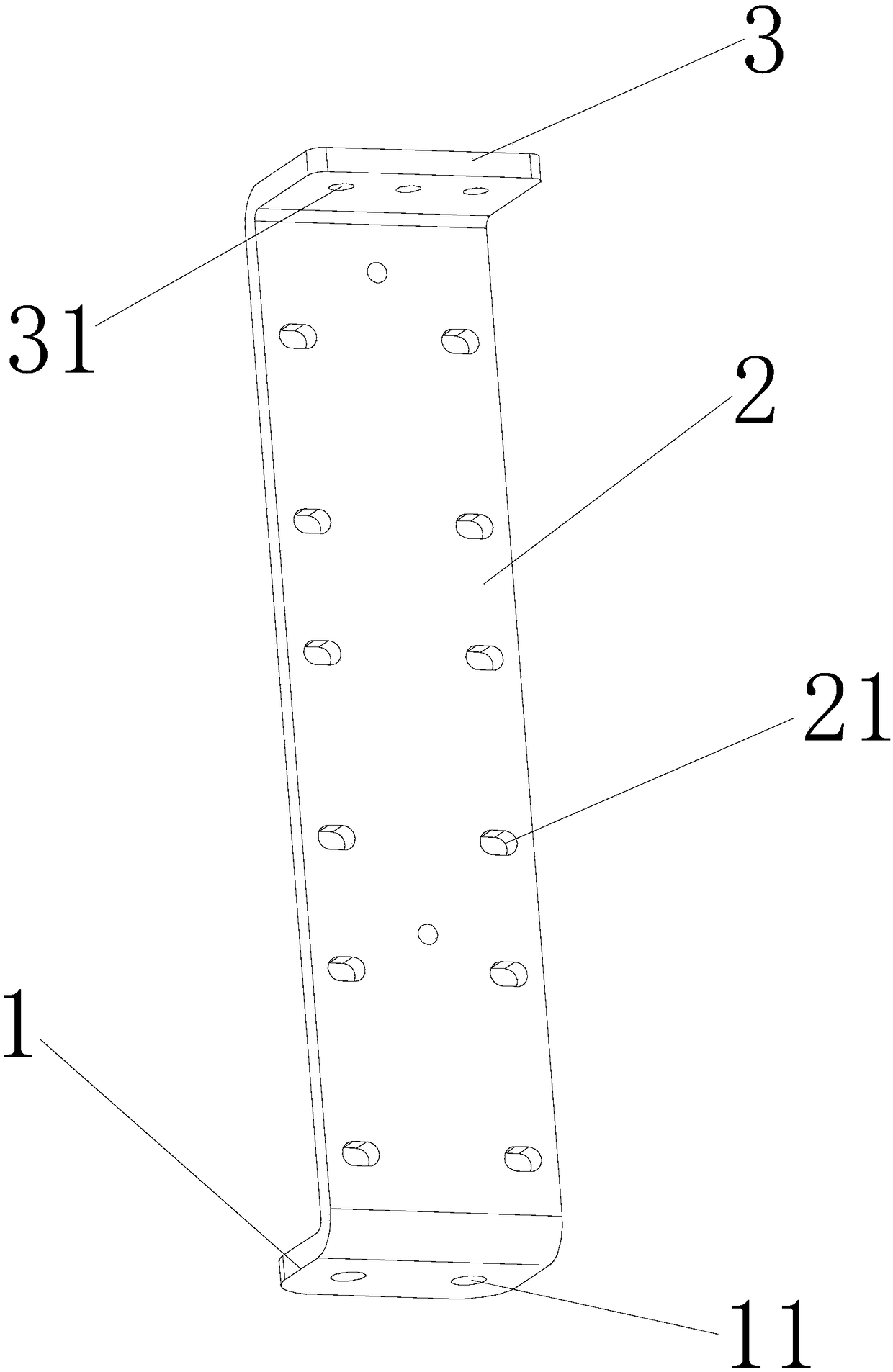

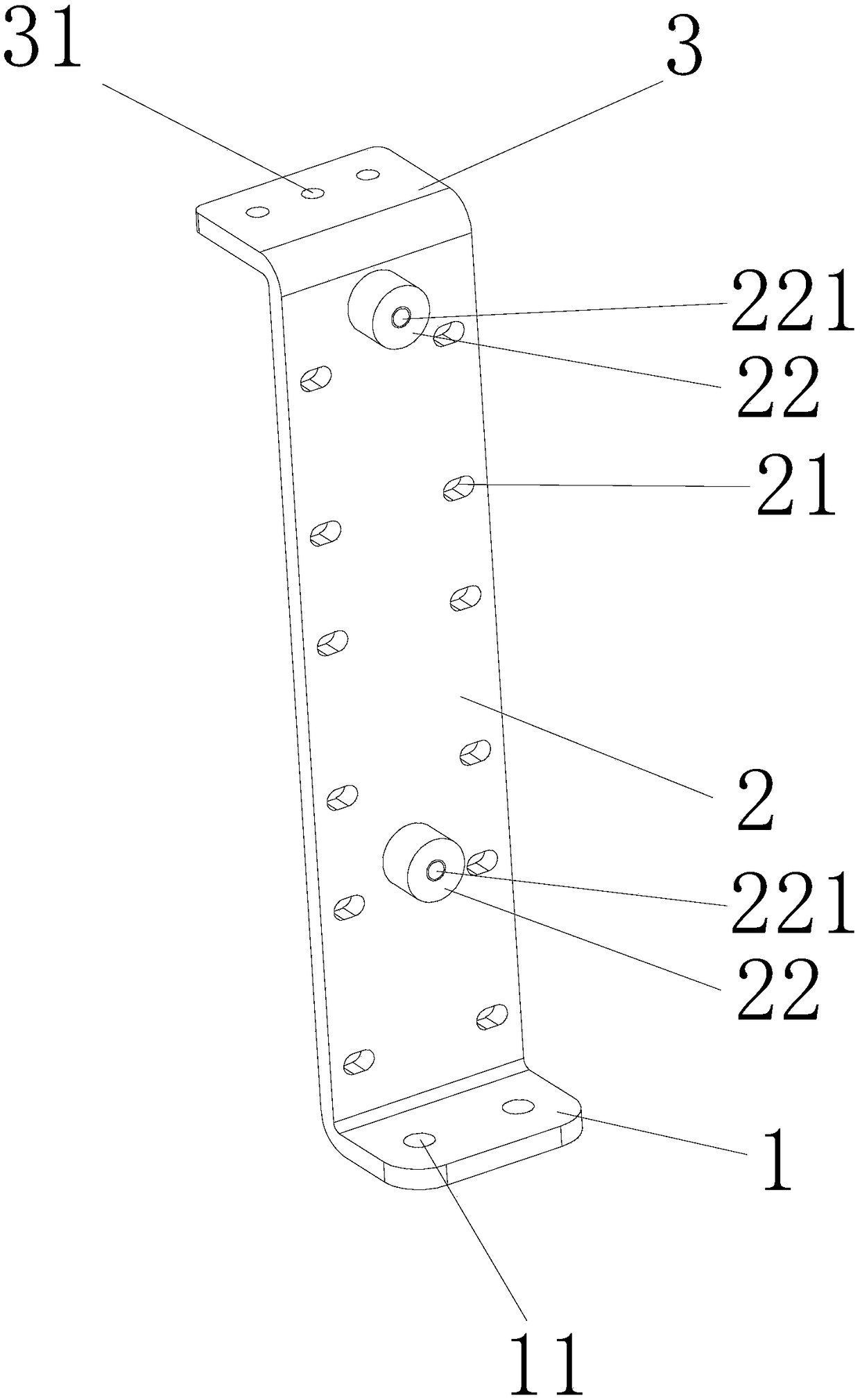

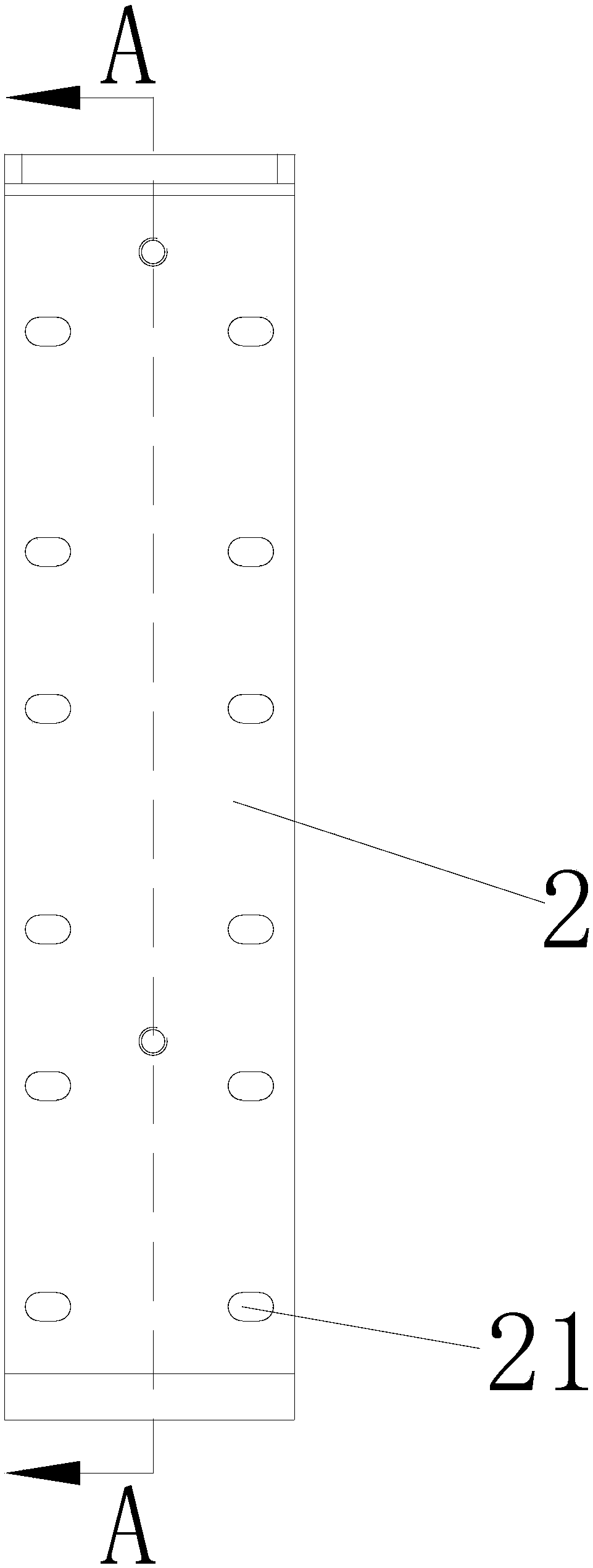

[0035] Such as Figure 1 to Figure 4 As shown, the present embodiment is a battery stack installation bracket, including an installation base plate 1 located at the bottom and a vertical support plate 2 erected from the installation base plate 1, and a plurality of first installation holes 11 are arranged on the installation base plate 1, vertically The support plate 2 is provided with several rows of second mounting holes 21 from bottom to top.

[0036] The top of the vertical support plate 2 is provided with a top support plate 3 , and the top support plate 3 is provided with a plurality of third mounting holes 31 .

[0037] The vertical support plate 2 is also protrudingly provided with several studs 22 , and screw holes 221 are arranged on the studs 22 .

[0038] The number of the studs 22 is two.

[0039] The two studs 22 are spaced up and down.

[0040] The number of the second mounting holes 21 in each row is at least two.

[0041] The installation bottom plate 1 an...

Embodiment 2

[0044] Such as figure 1 , Figure 5 , Image 6 , Figure 7 with Figure 8 As shown, a fuel cell includes a box body 4, a case cover, a stack module 6, a stack mounting bracket 10, a positive bus bar copper bar 7 and a negative bus bar copper bar 8, a stack module 6, a positive bus bar copper bar 7 and The negative busbar copper bar 8 is installed inside the box body 4 through the stack mounting bracket 10. The stack module 6 is formed by stacking several fuel cell cells 60 from bottom to top. The stack mounting bracket 10 described above is the For the stack installation bracket 10 described above, the bottom plate 41 inside the box body 4 is provided with a mounting boss 411, and the mounting bottom plate 1 is installed on the mounting boss 411 through the first mounting hole 11 through screws, and the stack mounting bracket is in the shape of Z The fuel cell unit 60 is locked on the vertical support plate 2 by using screws through the second mounting hole 21, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com