A fault diagnosis method for hydrometallurgical leaching process based on dcd

A hydrometallurgy and fault diagnosis technology, applied in program control, instrumentation, test/monitoring control system, etc., can solve the problems of complex hydrometallurgy process, many process parameters, and difficulty in fault diagnosis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

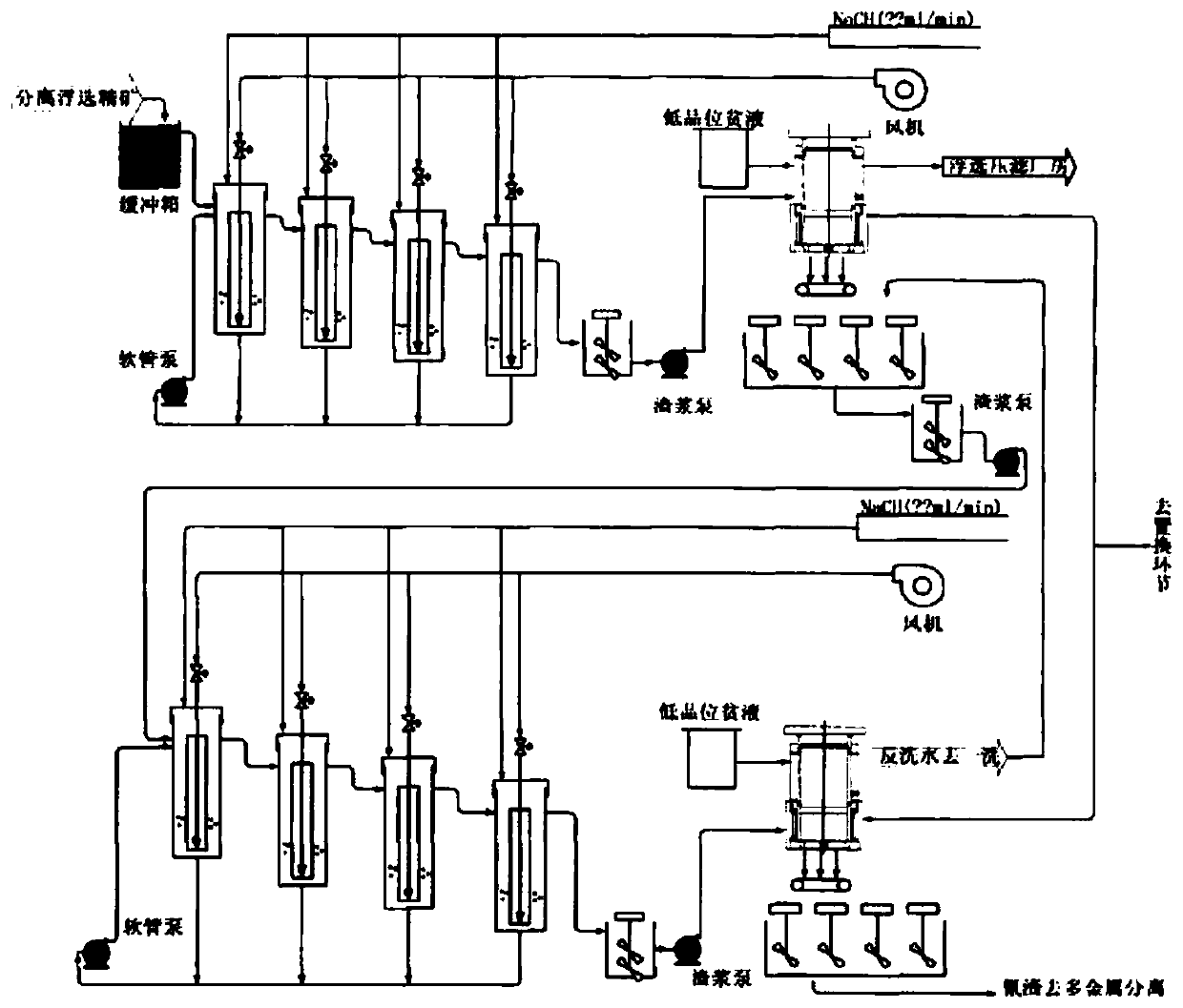

[0092] The present embodiment provides a DCD (Dynamic Causality Diagram, dynamic causality diagram)-based method for diagnosing a fault in a hydrometallurgical leaching process, comprising the following steps:

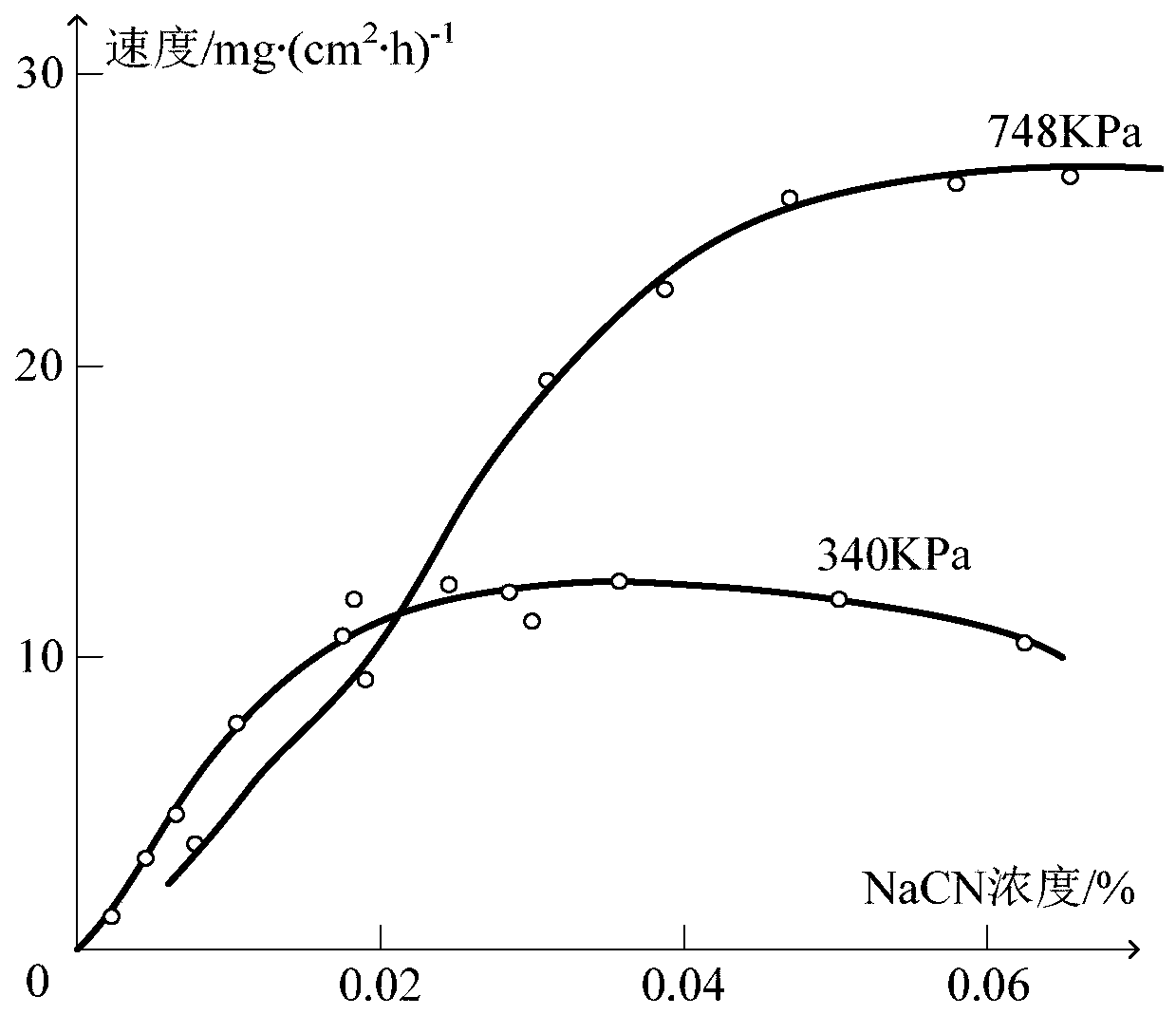

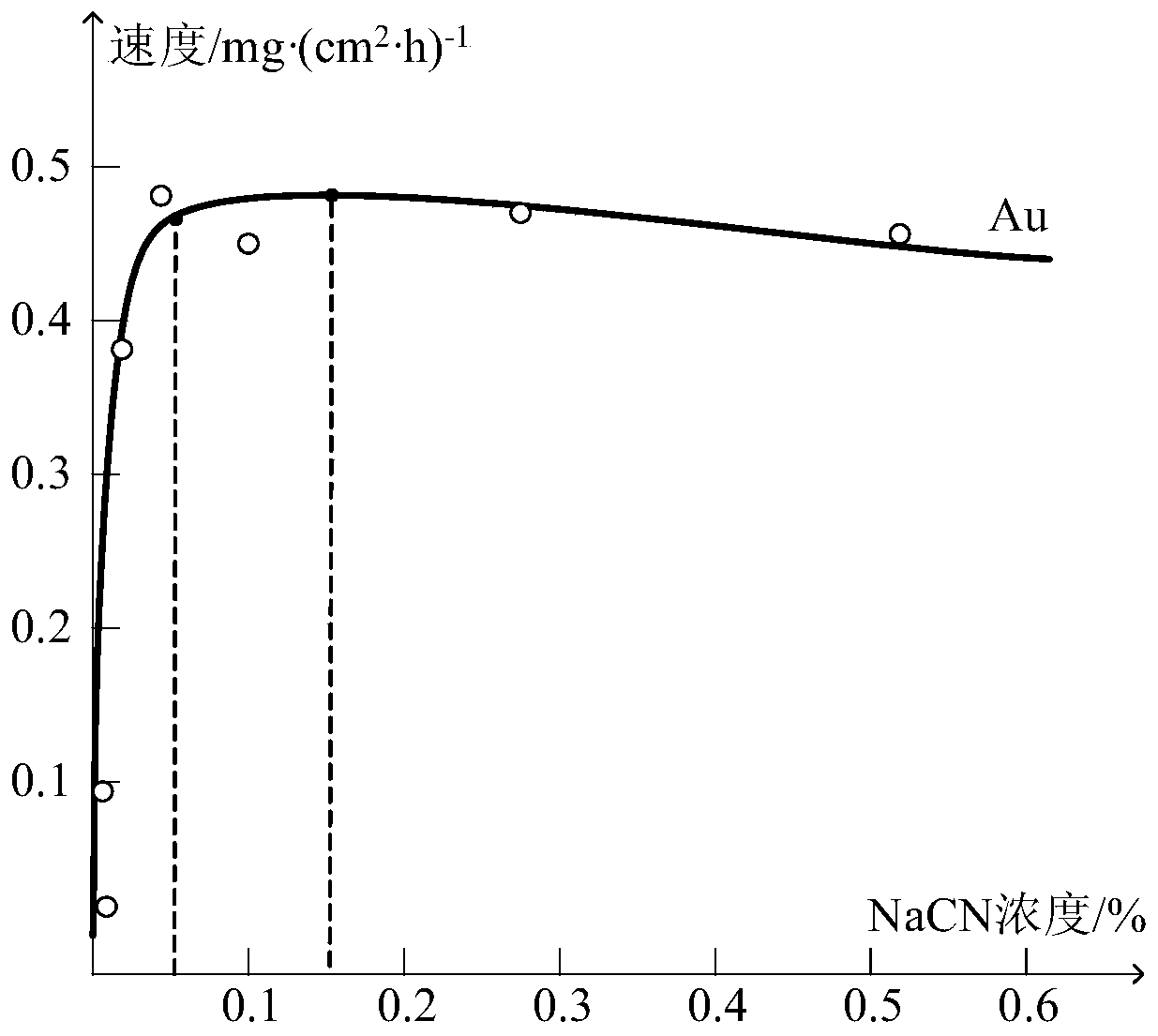

[0093] Step A: Establish the DCD knowledge base model of the diagnostic object. Specifically, establish a dynamic causal graph knowledge base by extracting information from expert knowledge and process data as prior information, including the selection and definition of basic event and intermediate event variables, variable The connection and establishment of the causal relationship among them, and the setting of various parameters required by each variable;

[0094] Step B: Use the real-time operation data collected in the actual process to monitor whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com