Deadlock-free control method for an automated manufacturing system containing uncontrollable events

A technology of automatic manufacturing system and control method, applied in general control system, control/regulation system, program control, etc., can solve problems such as insufficient utilization of resources, reduction of production efficiency, state explosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

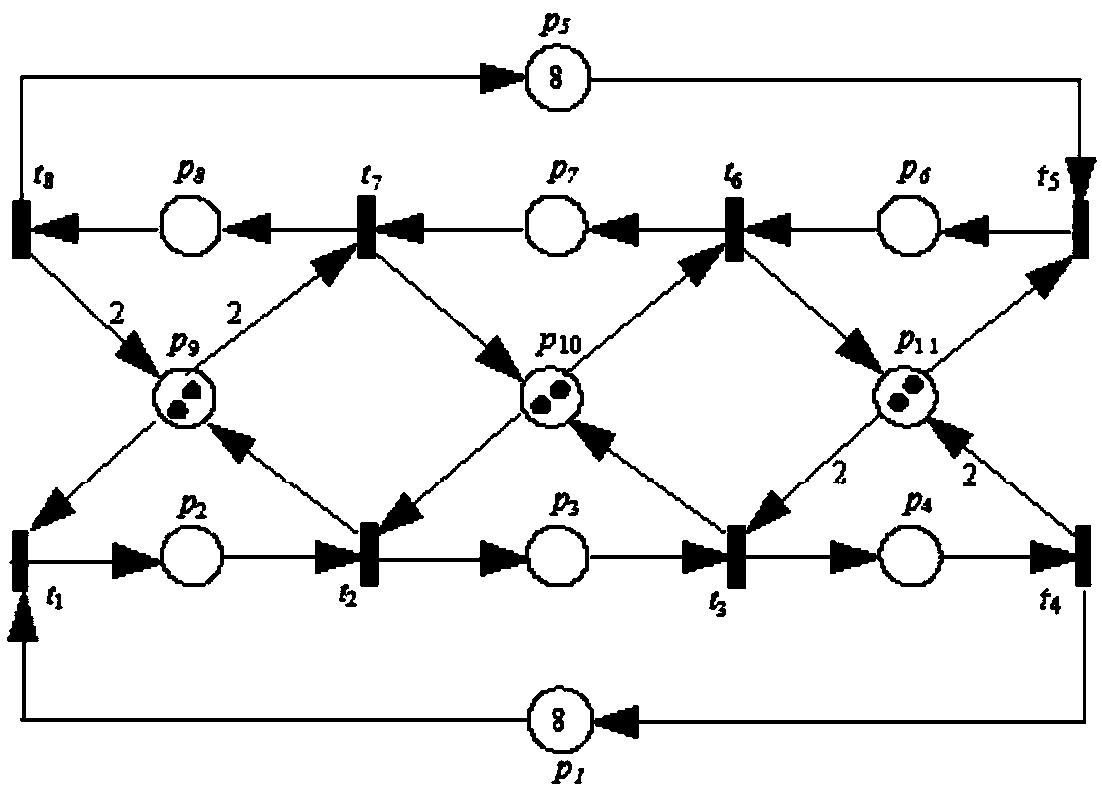

[0064] Definition 1: The structure of Petri net (PN) is a directed graph described by 4 elements:

[0065] PNS = (P, T, I, O)

[0066] here:

[0067] (1) P={p 1 ,...,p n} is a finite set of places, n>0 is the number of places;

[0068] (2)T={t 1 ,...,t n} is a finite set of transitions, m>0 is the number of transitions.

[0069] (3) I:P×T→N is an input function, which defines the set of weights of directed arcs from P to T, where N={0,1,...} is a non-integer set;

[0070] (4) O:T×P→N is the output function, which defines the set of repetitions or weights of directed arcs from T to P,

[0071] In the directed graph representing the PN structure, the place is represented by a circle; the transition is represented by a rectangle or a thick solid line segment; if the input function from place p to transition t is a non-negative integer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com