Monitoring method and system of SMT production process

A monitoring system and production process technology, applied in the monitoring method and system field of SMT production process, can solve the problems of inability to guarantee the fully automatic placement of the placement machine, wrong material supply of the placement machine, and material error rate affecting the placement progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

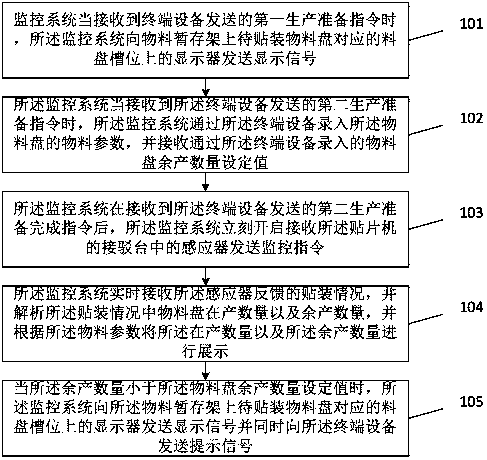

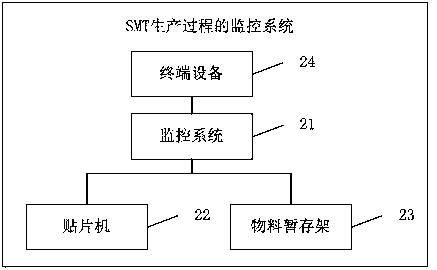

[0035] Hereinafter, the present application will be described in detail with reference to the drawings and embodiments. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

[0036] In view of the inability to monitor the placement progress on the placement machine and the normal supervision of the supply of materials during the placement process, only relying on the manual monitoring of the material staff will affect the placement progress and the error rate of the materials, and it is impossible to guarantee that all placement machines can achieve full Automated placement. This embodiment provides a method for monitoring the SMT production process, which can freely read the progress of the patch, avoid errors caused by human monitoring, make the chip production intelligent, and improve the monitoring efficiency of the SMT production process.

[0037] The present e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com