Real-time measurement method and strengthening method for heat release of Ti-C igniting agent

A technology of real-time determination and igniting agent, which is applied in the direction of chemical analysis by combustion, can solve the problems of incomplete combustion reaction, low sample consumption, and little data, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

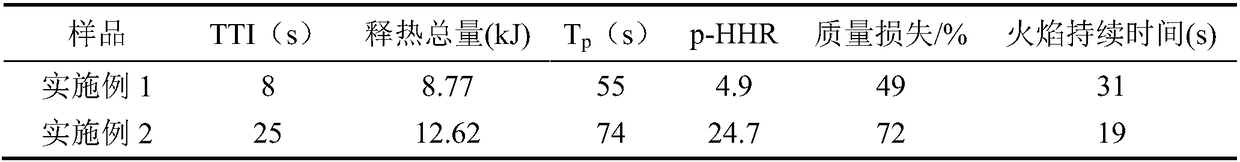

[0015] This implementation provides a method for measuring the amount of heat released by Ti-C igniters in real time. The titanium powder (average particle diameter is 0.05mm) and 3g of natural scale (average particle diameter is 0.05mm) carbon powder mixed with formula quantity 12g (mass After the ratio 4:1) is uniform, it is pressed into a cylindrical shape under a pressure of 2.0MPa, and placed in a well-adjusted cone calorimeter, and the cone calorimeter is used to monitor and record the ignition of Ti-C in real time Parameters such as heat release, temperature, and quality of the agent in the reaction process, the results are shown in Table 1.

Embodiment 2

[0017] This embodiment provides a method for real-time determination of the enhanced heat release of Ti-C igniters. The test process is the same as in Example 1, except that the natural flaky graphite carbon powder is completely replaced by expandable graphite, which meets the requirements of the average particle diameter. It is 0.15mm, and the expansion ratio reaches 300mL / g. The results are shown in Table 1.

[0018] It can be seen from Table 1 that parameters such as the heat release and quality of the Ti-C igniter can be measured in real time and accurately; at the same time, expandable graphite is used to replace natural flake graphite carbon powder, and the heat release is significantly increased by about 43.9%. , and its mass loss is large, indicating that expandable graphite can promote its full reaction and enhance its heat release by replacing the scaly carbon powder.

[0019] The physicochemical property parameter of test when reacting 250s in the embodiment of tabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com