Heat supply pipeline leakage detection system and method based on infrasound waves and reference point

A heating pipeline and leakage detection technology, which is applied in the pipeline system, detects the appearance of fluid at the leakage point, and uses the liquid/vacuum degree to measure the liquid tightness, etc. It can solve the problems of the influence of calculation results and the non-constant speed of sound waves, etc. , to achieve the effect of reducing the workload of on-site investigation and improving the calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to enable those skilled in the art to better understand the technical solutions in the embodiments of the present invention, and to make the above-mentioned purposes, features and advantages of the embodiments of the present invention more obvious and understandable, the following describes the technical solutions of the present invention through the accompanying drawings and embodiments The technical solution is further described in detail.

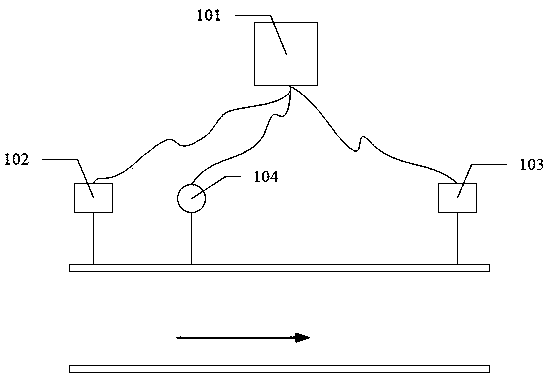

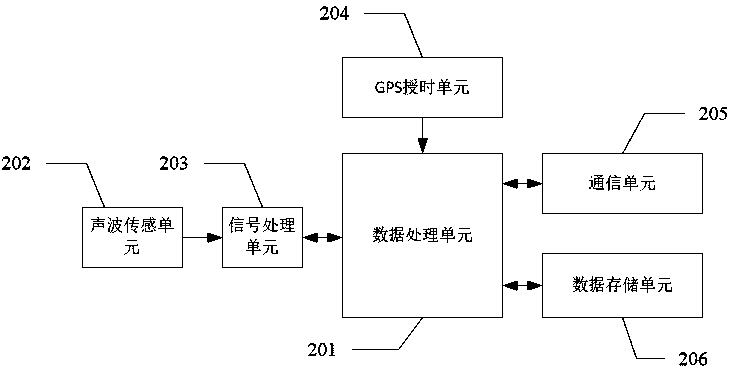

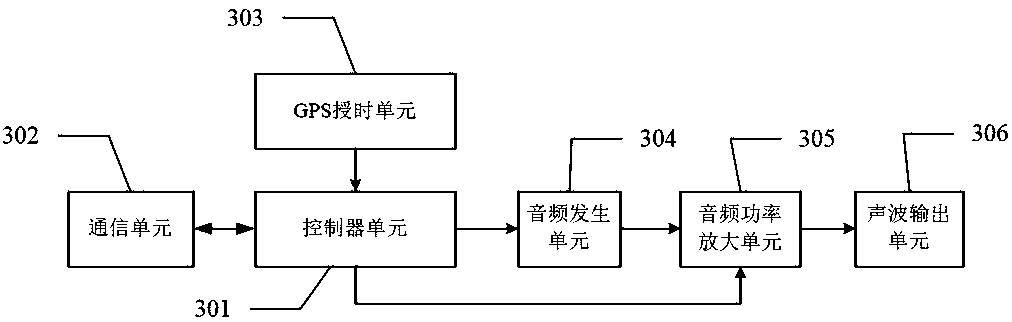

[0039] The present invention relates to a heating pipeline leakage monitoring system based on infrasonic waves and reference points, as attached figure 1 The heating pipeline leakage detection system includes: a central control system 101 , an upstream acoustic wave monitoring device 102 , a downstream acoustic wave monitoring device 103 and a sound source device 104 . The central control system 101 has a built-in third GPS timing unit. Wherein, the distance between the upstream acoustic wave monitoring device 102 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com