Large-flow PP-R pipeline system

A technology of PP-R and pipeline system, which is applied in the field of drinking water pipeline system, which can solve the problems of reduced water comfort, water cut-off, insufficient water pressure at high floors, etc., and achieve the effects of reducing resistance, increasing flow rate, and increasing flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

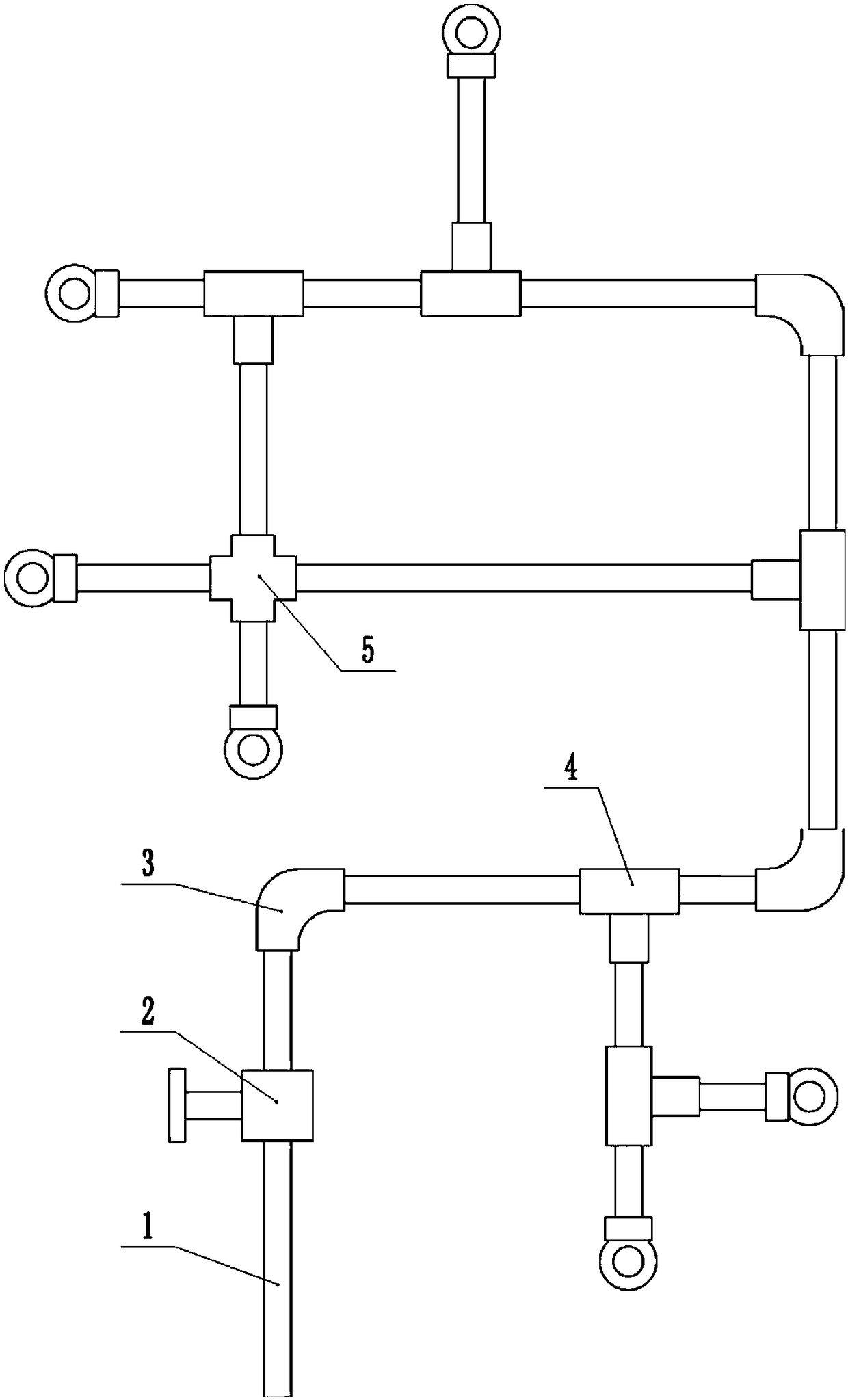

[0023] Embodiment one is basically as attached figure 1 Shown: a large-flow PP-R pipeline system, including a main water pipe 1 and two branch pipes, a gate valve 2 is installed on the main water pipe 1, a downstream tee 4 is connected to the main water pipe 1, and the two branch pipes are connected to the downstream tee 4, such as Image 6 As shown, the downstream tee 4 includes a straight pipe 23 and an elbow 22, the elbow 22 is connected to the right side of the straight pipe 23, and the ratio of the radius of curvature of the central arc of the elbow 22 to the radius of the inner diameter of the elbow 22 is 5.5 : 1, the inner passage diameter of the elbow 22 is equal to the inner passage diameter of the straight pipe 23, and the main water pipe 1 and some branch pipes are all provided with elbows 3, such as Figure 5 As shown, the elbow 3 includes a connecting pipe 25, the inlet and outlet of the connecting pipe 25 are connected with a short pipe 24, the ratio of the radi...

Embodiment 2

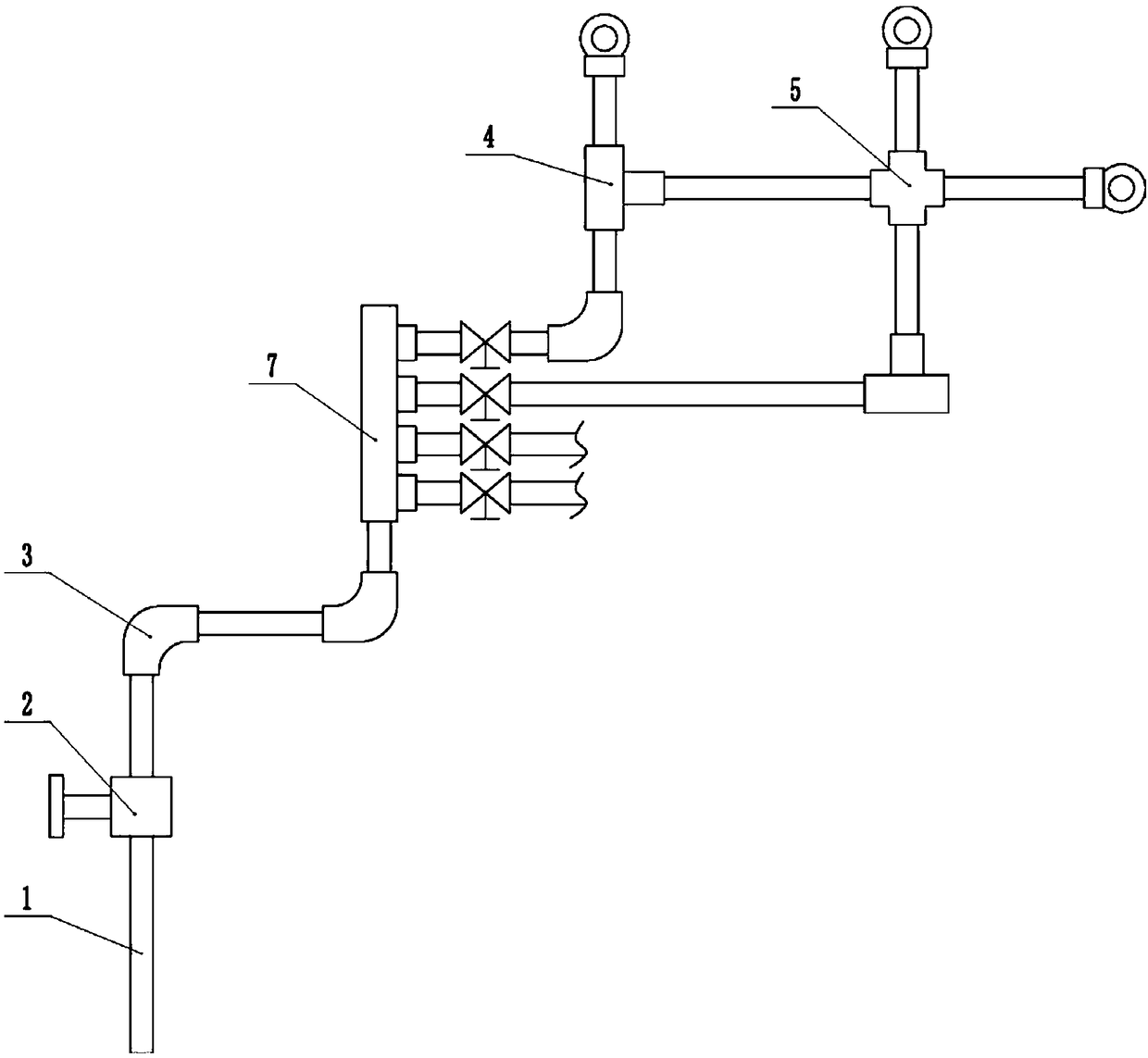

[0028] Embodiment two is basically as attached figure 2 , Figure 5 , Image 6 with Figure 7 Shown: The difference with Embodiment 1 is that the main water pipe 1 is connected with a water separator 7, and there are four branch pipes, and the four branch pipes are all connected with the water separator 7, and the flow rate of the pipeline system is increased by 25% year-on-year.

Embodiment 3

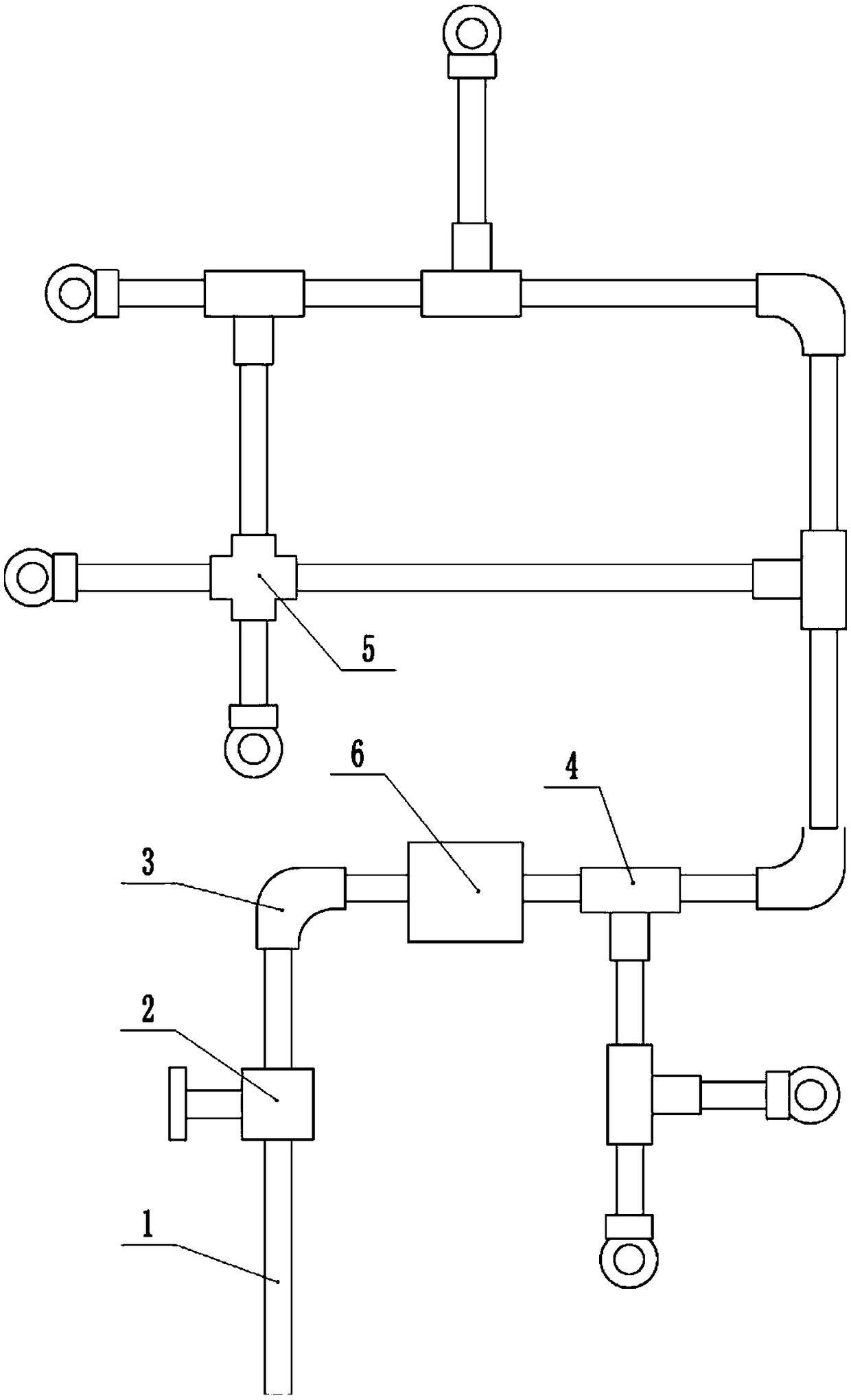

[0029] Embodiment three is basically as attached image 3 , Figure 4 , Figure 5 , Image 6 with Figure 7 As shown: the difference from Embodiment 1 is that an alarm device 6 is installed on the main water pipe 1, and the alarm device 6 includes a mounting frame 8, which is located above the main water pipe 1, and the main water pipe 1 is connected with a pressure pipe 15, and the pressure pipe 15 is slidingly connected with a first rack 13, a first spring 28 is connected between the first rack 13 and the mounting frame 8, the first rack 13 is meshed with the first gear 12, and the mounting frame 8 is connected with a vertical sliding The wedge bar 11 has gear teeth on the wedge bar 11, and the wedge bar 11 meshes with the first gear 12 through the gear teeth. Two springs 29, the drive wedge bar 10 are laterally slidably connected to the mounting frame 8, the mounting frame 8 is slidably connected with a pressing wedge 9 for pressing the main water pipe 1, and the drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com