A reciprocating compressor air supply mechanism

A compressor and reciprocating technology, which is applied in the field of reciprocating compressor air supply mechanism, can solve the problems such as inability to realize air supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

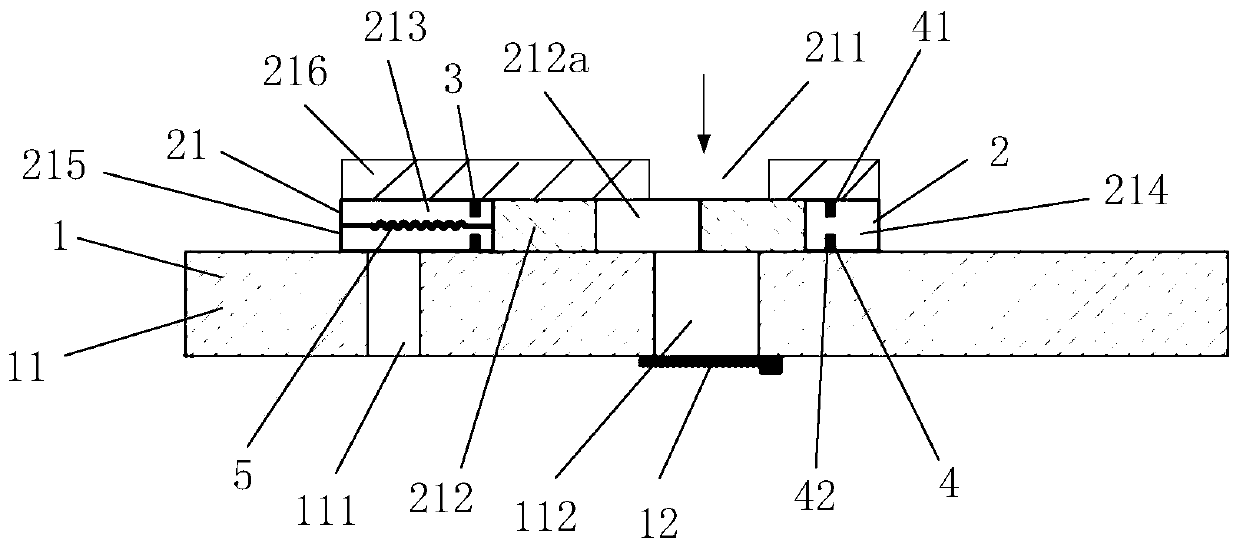

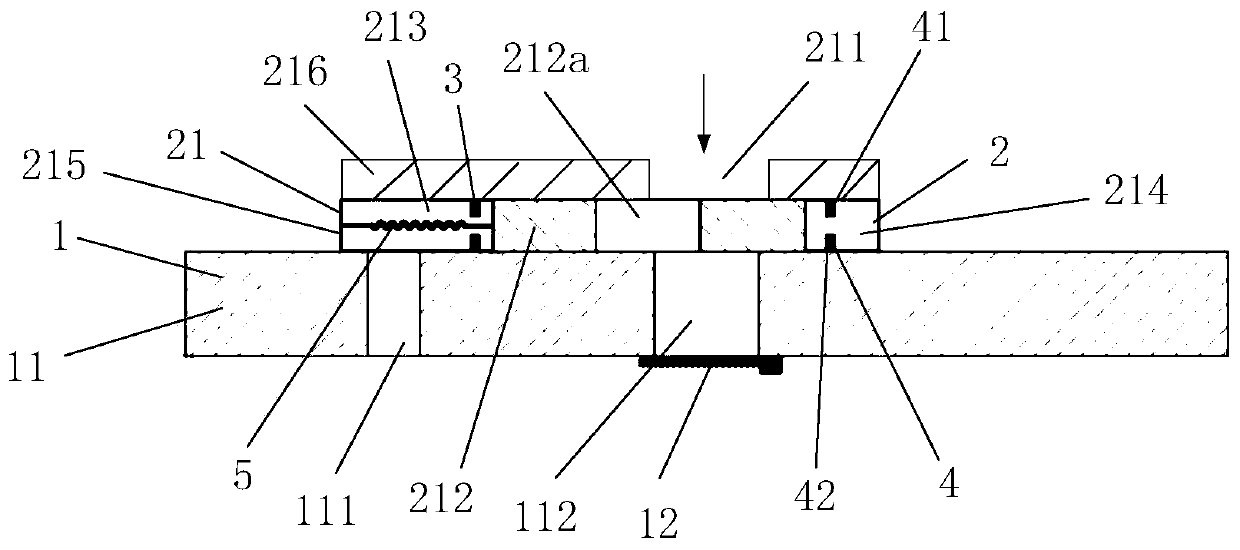

[0024] Such as figure 1 As shown, the figure schematically shows that the air supply mechanism of the reciprocating compressor includes an air supply valve structure 1 and a shut-off valve structure 2 .

[0025] In the embodiment of the present application, the air supplement valve structure 1 includes a valve plate 11 and an air supplement valve 12 arranged on the upper end of the cylinder body (not shown in the figure), wherein the valve plate 11 is in a spaced structure There is a pressure introduction hole 111 and an air supply hole 112 , and the air supply valve 12 is arranged in the air supply hole 112 . That is to say, the role of the air supply valve 12 is mainly to flexibly control the opening and closing of the air supply orifice 112 . However, it should be noted that since the structure and composition of the supplementary air valve 12 are well known to those skilled in the art, for the sake of space saving, no detailed description is given here.

[0026] The cut-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com