Tensioning device suitable for underground construction defective anchor rod

A tensioning device and underground construction technology, which is used in the installation of bolts, mining equipment, earth-moving drilling, etc. The problem is to achieve the reliability of the bolt tension test process, ensure the overall stability, and prevent the bolt from failing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below.

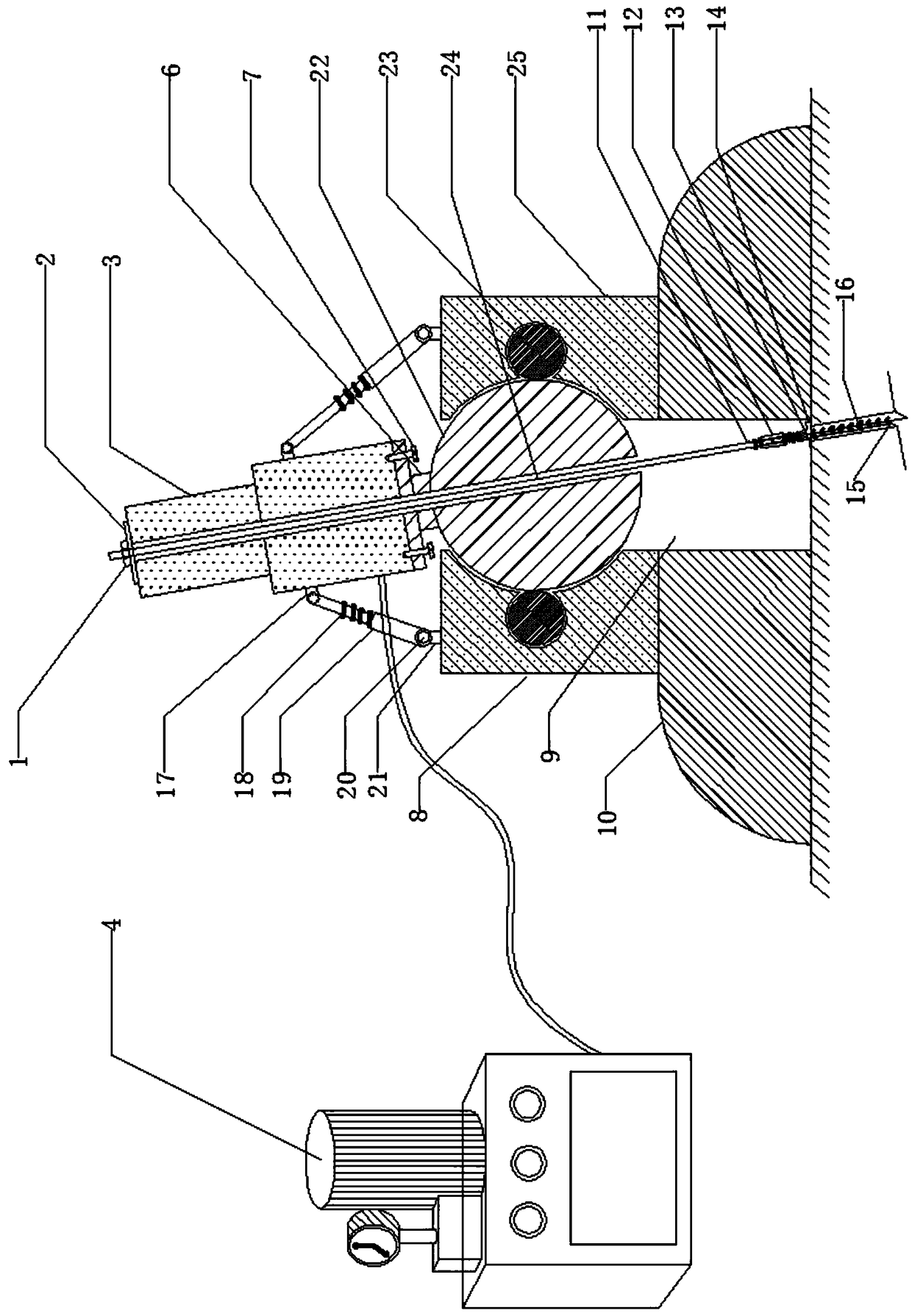

[0027] As shown in the figure, the present invention includes a hollow oil cylinder 3, an oil cylinder fixed arm 5, an angle adjustment device 8, a round table support 10, a pulling connecting rod 11 and a hydraulic power source 4,

[0028] An operating groove 9 is provided on the round platform support 10;

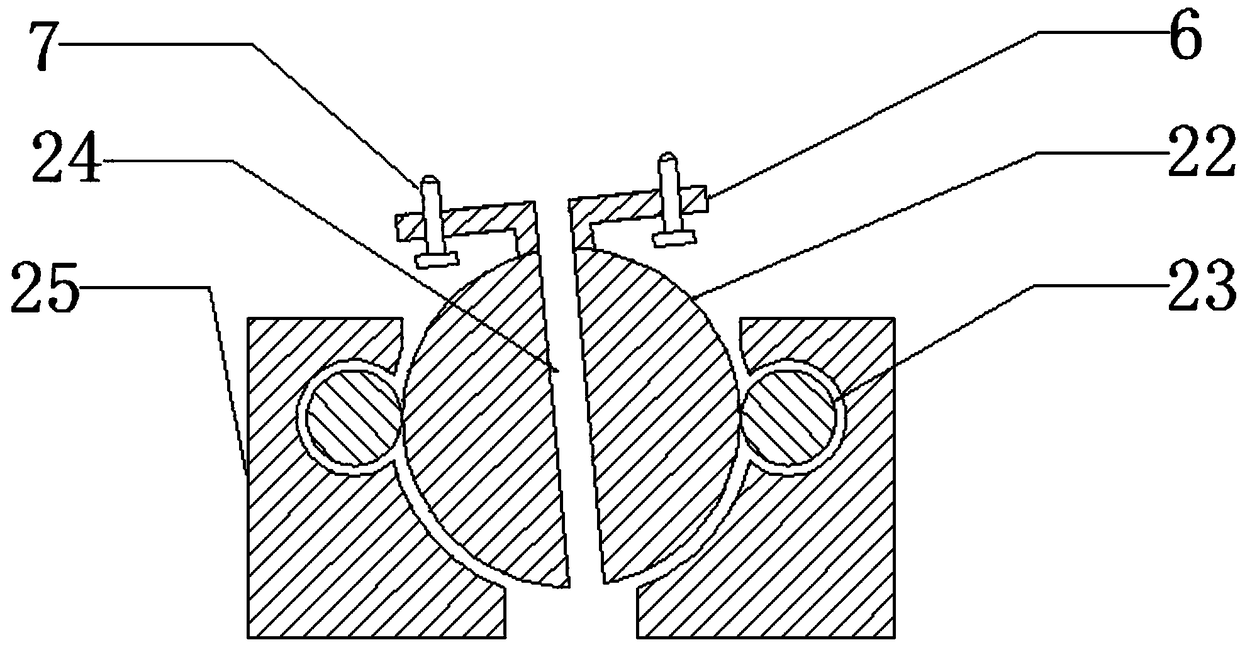

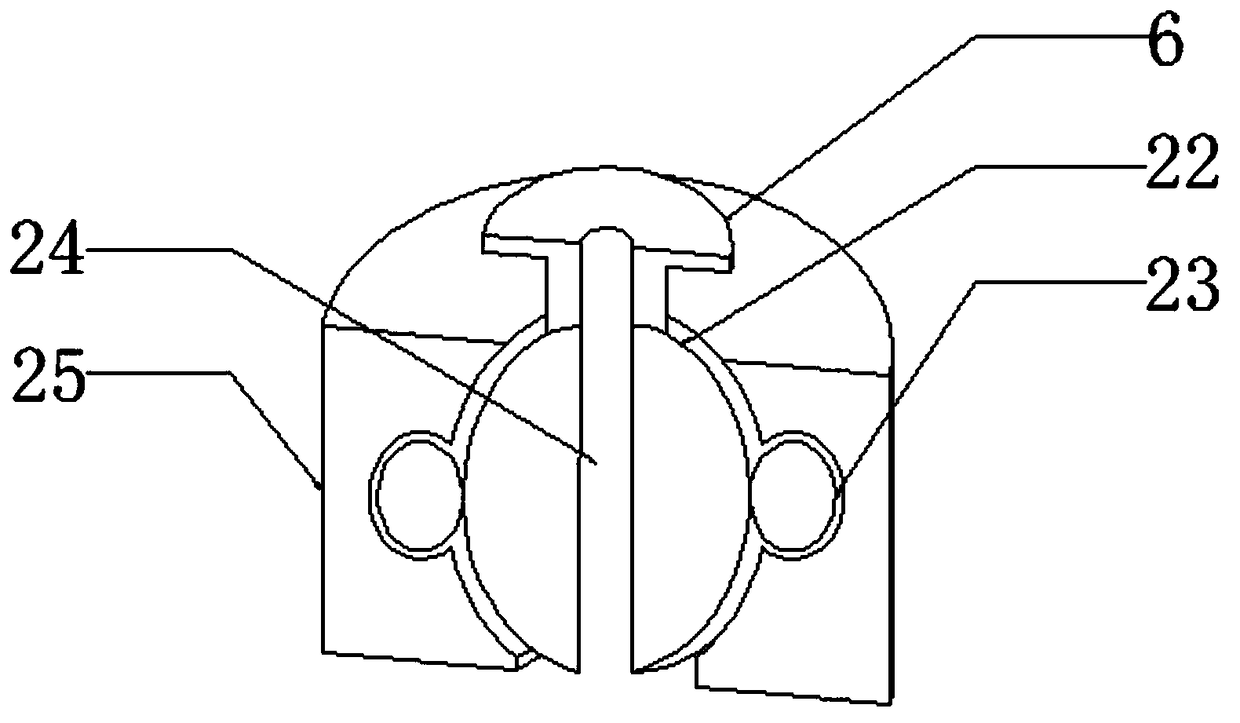

[0029] The angle adjustment device 8 includes a female rotating ball 22 and a rotating seat 25, the rotating seat 25 is fixed on the top of the round platform support 10, a large arc groove is opened in the described rotating seat 25, and the female rotating ball 22 is placed on the large arc In the groove, a cylindrical through groove is provided at the bottom of the large circular arc groove to communicate with the operating groove 9, and the oil cylinder support seat 6 is fixed on the female rotating ball 22, and the oil cylinder support seat 6 has a 22 sphere centers of the female rotating ball. Central ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com