Center joint fixed member for fabricated integrated wall tile system and assembly method thereof

A wall brick, fixed technology, applied in building construction, covering/lining, construction, etc., can solve the problems of large space occupied by the back accessories keel of wall bricks, reduced indoor space utilization, high labor and material costs, To achieve the effect of shortening the construction period, reducing the cost of disassembly, and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

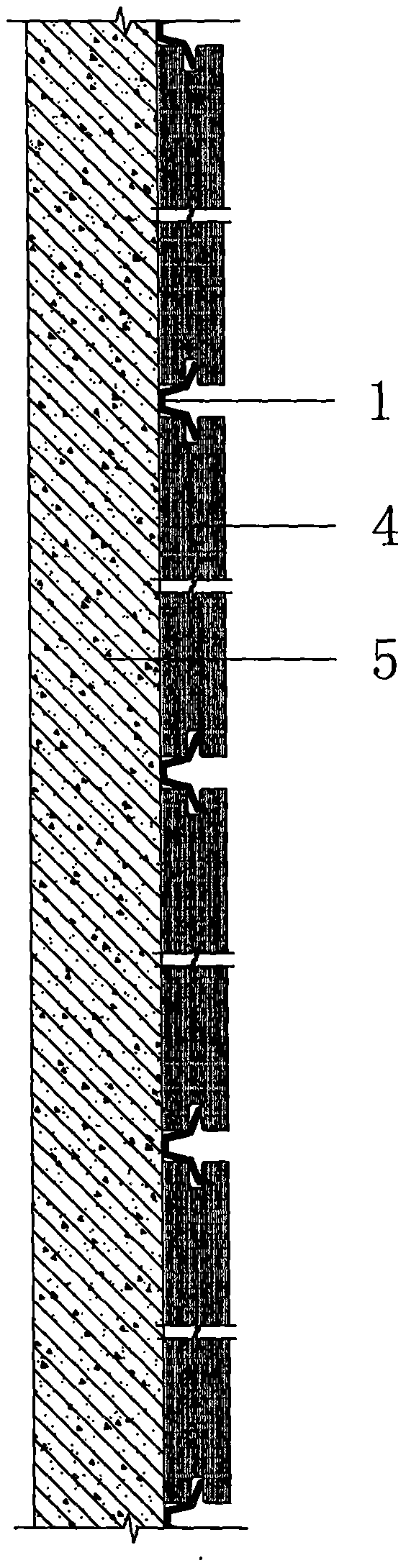

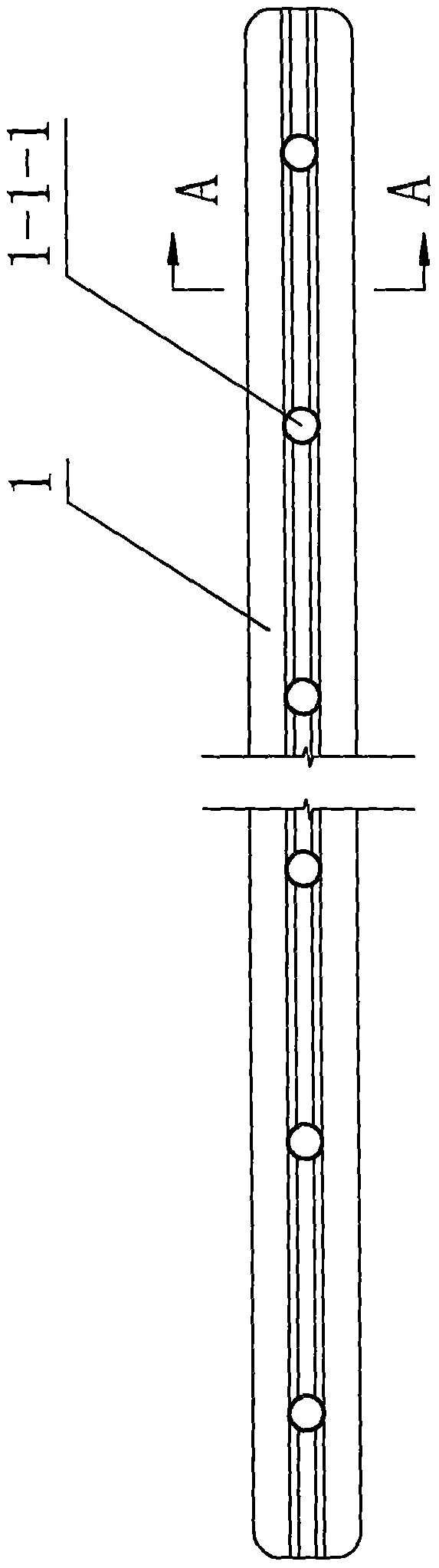

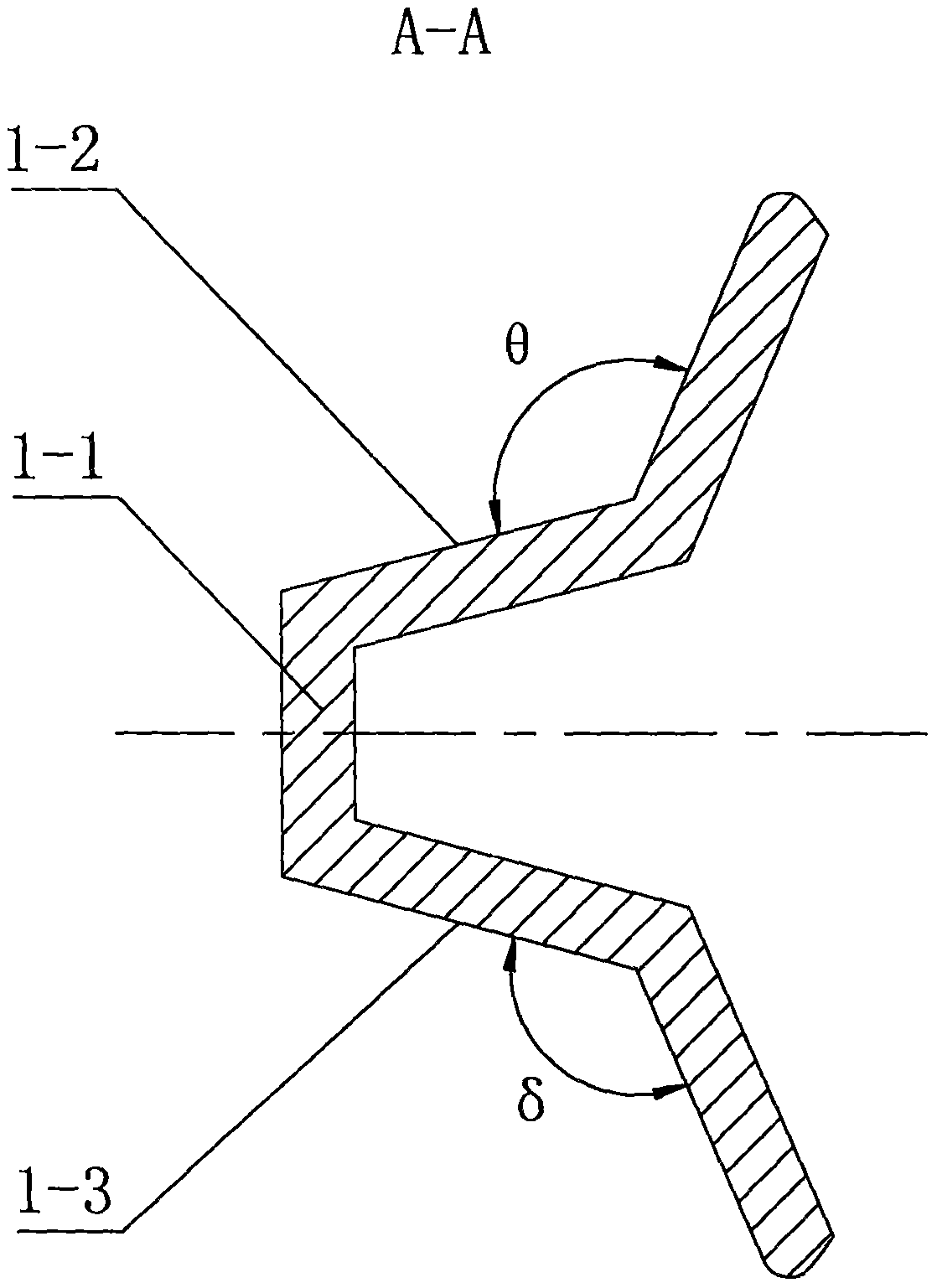

[0033] Specific implementation mode one: combine Figure 1 to Figure 3 , Figure 10 to Figure 14 , Figure 17 and Figure 18 Illustrate the present embodiment, a kind of prefabricated integrated wall brick system center seam fixed member of the present embodiment, it comprises cross member I 1, vertical member 2, L-shaped card 3 and wall face brick 4, and vertical member 2 is Right-angled pole-type components, the vertical component 2 is positioned and installed on the yin and yang corners of the wall, and the two sides of the vertical component 2 are symmetrically provided with a plurality of pairs of vertical fish scale punching holes 2-3 with the opening direction facing upwards, and each vertical component 2 An L-shaped card 3 is mounted on the vertical fish scale punching hole 2-3, and two grooves are respectively provided on both sides of the L-shaped card 3 to cooperate with the transverse member I 1, and two adjacent vertical members 2 are provided with A plurality ...

specific Embodiment approach 2

[0034] Specific implementation mode two: combination Figure 4 to Figure 6 , Figure 10 to Figure 14 , Figure 17 Describe this embodiment, an assembled integrated wall tile system of this embodiment, which is a fixed member in the middle, which includes a vertical member 2, an L-shaped card 3, a wall tile 4, a transverse member II6, a support body 7 and a connector 8. The vertical member 2 is a right-angled pole-type member. The vertical member 2 is positioned and installed at the male and female corners of the wall. The two sides of the vertical member 2 are symmetrically provided with a plurality of pairs of vertical fish scale punching holes 2-3 with the opening direction facing upward. , each pair of longitudinal fish scale punching holes 2-3 of the vertical member 2 is clamped with an L-shaped card 3, and the two sides of the L-shaped card 3 are respectively provided with two grooves that cooperate with the transverse member II 6, and two adjacent vertical A plurality ...

specific Embodiment approach 3

[0035] Specific implementation mode three: combination Figure 7 to Figure 14 and Figure 17Describe the present embodiment, a prefabricated integrated wall tile system center joint fixed member of this embodiment, which includes a vertical member 2, an L-shaped card 3, a wall tile 4 and a transverse member III9, the vertical member 2 is a right angle Vertical member, the vertical member 2 is positioned and installed at the male and female corners of the wall, and the two sides of the vertical member 2 are symmetrically provided with a plurality of pairs of longitudinal fish scale punching holes 2-3 with the opening direction upward, and each pair of vertical member 2 An L-shaped card 3 is clamped on the vertical fish scale punching hole 2-3, and two grooves are respectively provided on both sides of the L-shaped card 3 to cooperate with the transverse member III9, and a plurality of grooves are arranged between two adjacent vertical members 2. Cross member III9, cross member...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com