Concrete composite wall prefabricated wallboard combined connecting piece and composite wall preparation method

A technology of prefabricated wall panels and concrete, applied in the direction of walls, building components, buildings, etc., can solve the problems of reduced efficiency of prefabricated components and the inability to prefabricate left and right wall panels at the same time, so as to improve factory production efficiency, light weight and save steel. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

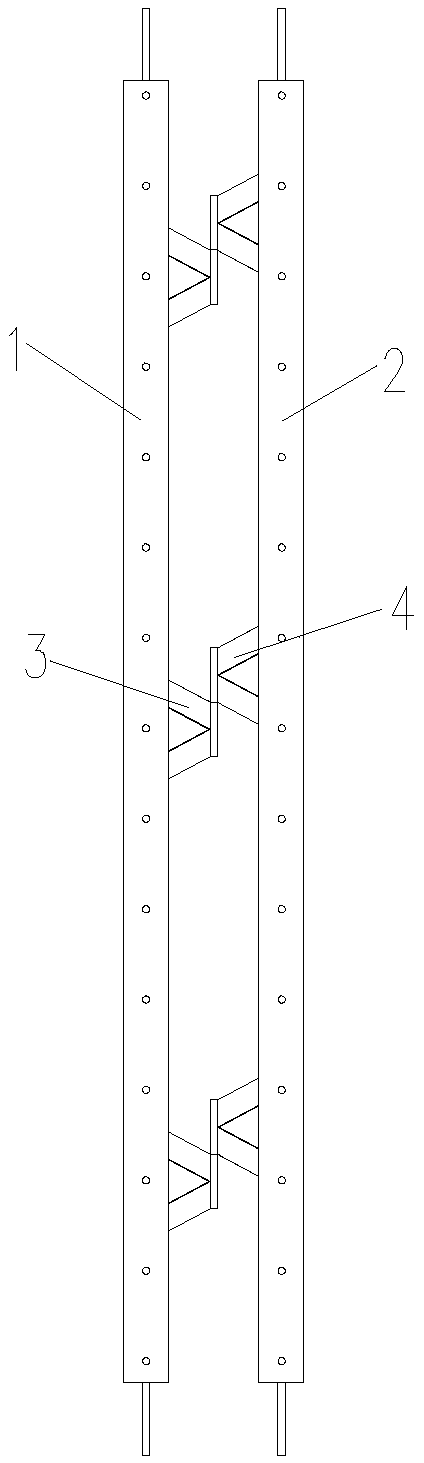

[0025] Such as figure 1 As shown, the combined connector of the present invention consists of a double Λ-shaped component A3 fixedly connected to the left prefabricated wall panel 1 and a double Λ-shaped component B4 fixedly connected to the right prefabricated wall panel 2 .

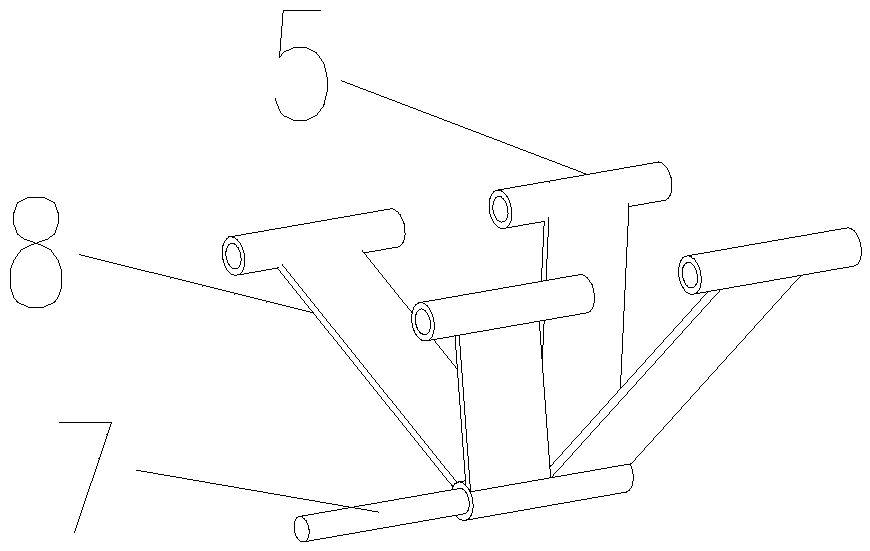

[0026] Such as figure 2 and image 3 As shown, the four bottom ends of the double Λ-shaped assembly A and the double Λ-shaped assembly B are respectively sleeves 5 (sleeves 5) that can be socketed with the longitudinal reinforcement 11 of the prefabricated wall panel (left prefabricated wall panel or right prefabricated wall panel). The hole diameter is slightly larger than the diameter of the longitudinal reinforcement). The top of the double Λ-shaped assembly A is a long socket 6, and the top of the double Λ-shaped assembly B is a plug 7 that can be plugged into the socket (the diameter of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com