Railway roadbed structure for reducing roadbed settlement deformation through opposite-pulling rib U-shaped groove

A technology of railway subgrade and U-shaped groove, which is applied in the directions of roads, tracks, buildings, etc., can solve the problems of large settlement of railway road basic body, large area occupation and large proportion of foundation treatment costs, so as to reduce settlement and land occupation. area, reducing uneven settlement, and the effect of material environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in combination with specific embodiments.

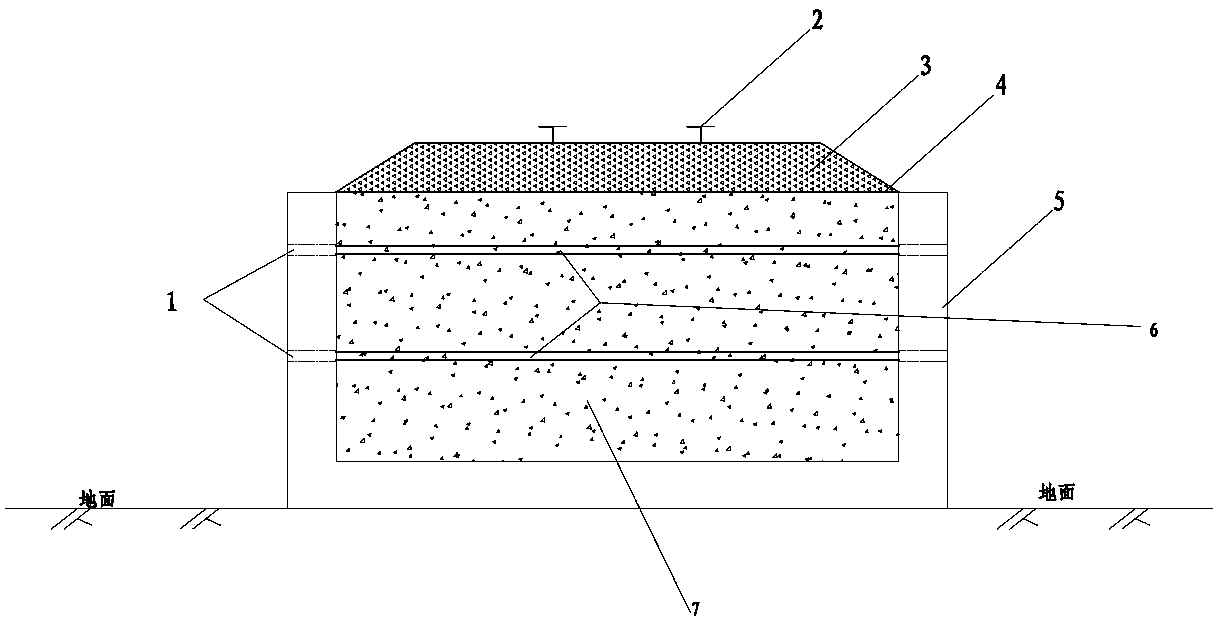

[0020] The present invention relates to a railway subgrade structure for reducing the subsidence and deformation of the U-shaped groove of the tension material. The bottom of the railway subgrade structure is provided with a reinforced concrete U-shaped groove 5 with the notch upward, and the reinforced concrete U-shaped groove 5 is filled with The roadbed filling material 7 is built, and the top of the roadbed filling material 7 is flush with the top edge of the reinforced concrete U-shaped groove 5, and the railway ballast 3 is arranged on the top, and the railway track structure 2 is arranged above the railway ballast 3. A layer of flexible water-proof material 4 is arranged on the top surface of the roadbed landfill material 7, which adopts two cloths and one membrane geotextile or a composite water-proof board.

[0021] The reinforced concrete U-shaped groove 5 is ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com