Ultrasonic wave cleaning agent and preparation method and application method

An ultrasonic and cleaning agent technology, applied in the field of ultrasonic cleaning agent and preparation, can solve the problems of poor performance and appearance of die-casting parts, increase the production cycle of die-casting parts, and many processing procedures of die-casting parts, and achieve good decontamination and rust prevention. The effect of shortening production cycle, increasing surface gloss and anti-rust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

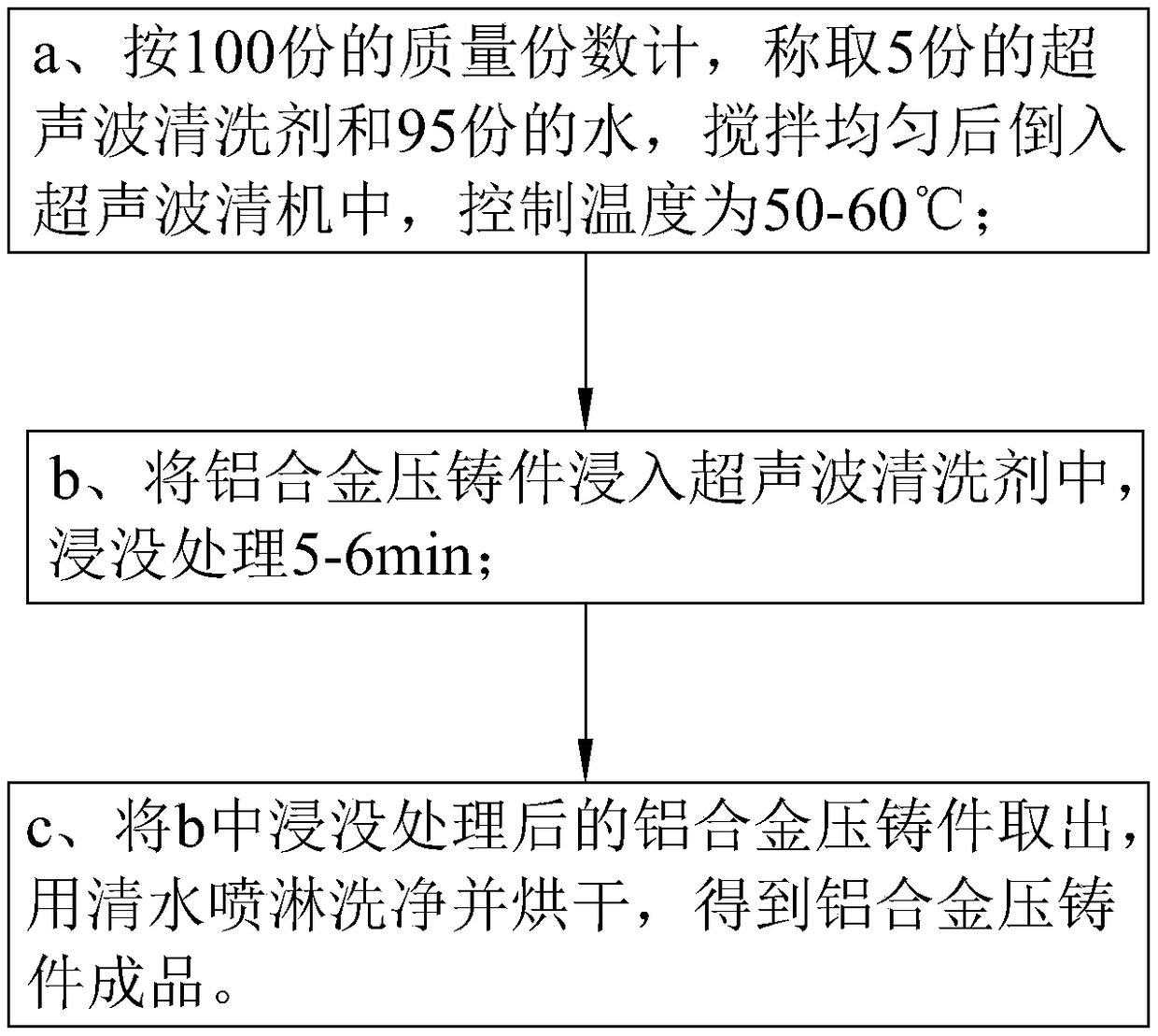

Method used

Image

Examples

Embodiment 1

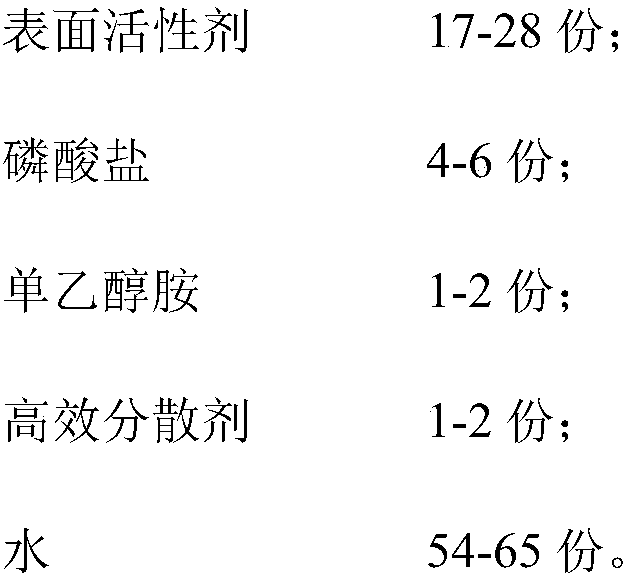

[0053] A preparation method of an ultrasonic cleaning agent, comprising the following steps:

[0054] S1. Weigh 54kg of water, reserve 4kg of water as reserved water, add the remaining 50kg of water into the stirring pot, then slowly add 1kg of propylene glycol block polyether into the stirring pot, and start the homogenizer to homogenize After 30s, control the rotation speed to 250r / min, and stir for 2min;

[0055] S2, add the surfactant that is mixed by the sodium dodecylbenzene sulfonate of 2kg, the fatty alcohol polyoxyethylene ether of 5kg and the nonylphenol polyoxyethylene ether of 10kg in the stirring pot in S1, at 55 Stir for 45min under the condition of ℃ and 280r / min;

[0056] S3, take by weighing 4kg of sodium tripolyphosphate and place it in the transfer barrel, dissolve it completely with the reserved water of 4kg in S1, obtain the sodium tripolyphosphate solution, and pour it into the stirring pot in S2;

[0057] S4. Add 1 kg of monoethanolamine and other clea...

Embodiment 2- Embodiment 10

[0059] Embodiment 2-embodiment 10 is all on the basis of the method of embodiment 1, the component of ultrasonic cleaning agent and the mass parts of each component are adjusted, and the mass unit is kg;

[0060] The components of the ultrasonic cleaning agent of embodiment 1-embodiment 10 and the quality of each component are as follows:

[0061]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com