Preparation method of sea cucumber visceral polypeptide

A sea cucumber viscera, enzymatic hydrolysis technology, applied in the field of food processing, can solve the problems of complex system components, poor sensory acceptance, irritating odor, etc., and achieve the effects of broadening the application range, improving acceptability, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

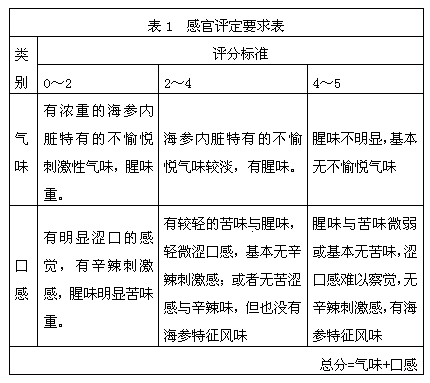

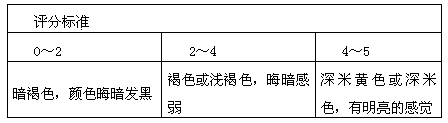

Examples

preparation example Construction

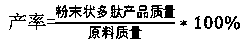

[0026] The present invention relates to a preparation method of sea cucumber viscera polypeptide, the steps comprising:

[0027] (1) Thawing and crushing: thaw the frozen sea cucumber viscera naturally at room temperature, then crush to obtain a slurry; the room temperature does not exceed 20°C;

[0028] (2) Enzymolysis: add compound enzyme to the slurry, the ratio of material to liquid is 1: (3-4), and carry out enzymolysis; the compound enzyme is a combination of collagenase, papain and lipase;

[0029] (3) Centrifugation: Centrifuge the enzymolysis system and take the supernatant; the centrifugation conditions are: cool the system to 30°C and centrifuge at 3000rpm for 10min, take the supernatant and centrifuge again at 6000rpm for 10min, and take the supernatant again;

[0030] (4) Concentration by nanofiltration: after the supernatant is passed through a nanofiltration membrane with a pore size of 1 to 2 nm, it is concentrated to a mass concentration of more than 30% to ob...

Embodiment 1

[0037] 1.1 Thawing of raw materials: Weigh 1 kg of frozen sea cucumber viscera harvested in spring, and thaw at 20°C for 3 hours.

[0038] 1.2 Tissue crushing: use a beater to perform homogenization treatment, and the homogenizer is 6000 rpm for 30 seconds to obtain a slurry. Crushed to improve enzymatic hydrolysis efficiency.

[0039] 1.3 Enzyme hydrolysis: add compound enzyme to the slurry, the ratio of material to liquid is 1:3, collagenase 0.05% (2*10 4 u / g), papain 0.05% (2*10 4 u / g), lipase 0.05% (1*10 4 u / g), pH 7, stirred during the process, after 3.5 hours of enzymatic hydrolysis at 50°C, the enzyme was deactivated at 90°C for 10 minutes.

[0040] 1.4 Centrifugation: After cooling the system to 30°C, centrifuge at 3000 rpm for 10 minutes, take the supernatant and centrifuge again at 6000 rpm for 10 minutes, and take the supernatant again. The centrifugation is carried out twice to improve the centrifugation efficiency.

[0041] 1.5 Nanofiltration desalination and...

Embodiment 2

[0044] 1.1 Thawing of raw materials: Weigh 1 kg of sea cucumber internal organs dissected in spring, and thaw at 20°C for 3 hours.

[0045] 1.2 Tissue crushing: Use a beater for homogenization treatment, and the homogenizer is 6000 rpm for 30 seconds.

[0046] 1.3 Enzymolysis: the ratio of solid to liquid is 1:3, collagenase 0.05% (2*10 4 u / g), papain 0.05% (2*10 4 u / g), lipase 0.05% (1*10 4 u / g), pH 7, stirring during the process, enzymolysis at 50°C for 2 hours, then cooling to 40°C for 1.5 hours, and 10 minutes at 90°C to inactivate the enzyme.

[0047] 1.4 Centrifugation: After cooling the system to 30°C, centrifuge at 3000 rpm for 10 minutes, take the supernatant and centrifuge again at 6000 rpm for 10 minutes, and take the supernatant again.

[0048] 1.5 Nanofiltration desalination and concentration: The pore size of the nanofiltration membrane is 1nm, and the system is concentrated to a mass concentration of more than 30%.

[0049] 1.6 Spray drying; the inlet air temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com