Production method of royal jelly honey fermented beverage

A technology of honey fermentation and production method, applied in the field of health drinks, can solve the problems of instability of the active ingredients of royal jelly, not easy to store for a long time, and reduced value of royal jelly, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

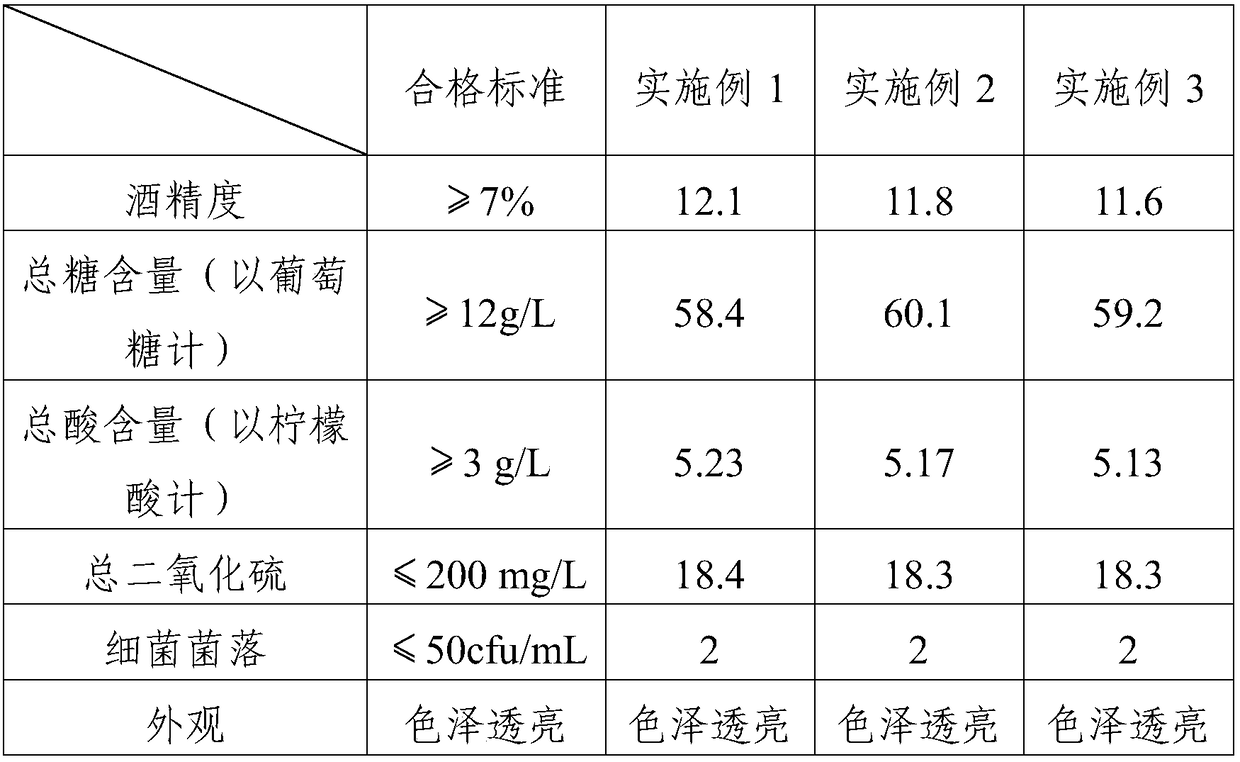

Examples

Embodiment 1

[0025] A method for producing a royal jelly honey fermented beverage, comprising the following steps:

[0026] (1) Add honey to an appropriate amount of clear water, heat up to 35°C and stir to make the honey completely melt into a homogeneous solution, add water until the mass concentration of the honey solution is 12%, heat up to 65°C and keep it for 15 minutes. Filter through 100μm gauze, and then filter with a filter membrane with a pore size of 0.65μm. After filtration, measure the transmittance. If the transmittance is less than 97%, re-filter the filter until the transmittance is greater than or equal to 97%;

[0027] (2) Pass into sulfur dioxide in above-mentioned honey solution, the sulfur dioxide feed rate is less than 20mg / L;

[0028] (3) Take French wine dry yeast and add it to 10% sucrose aqueous solution, activate it in a water bath at 38°C for 25 minutes;

[0029] (4) Control the temperature of the honey solution at 27°C, add activated French wine dry yeast, cu...

Embodiment 2

[0031] A method for producing a royal jelly honey fermented beverage, comprising the following steps:

[0032] (1) Add honey to an appropriate amount of clear water, heat up to 32°C and stir to make the honey completely melt into a homogeneous solution, add water until the mass concentration of the honey solution is 12%, heat up to 62°C and keep it warm for 18 minutes. Filter through 100μm gauze, and then filter with a filter membrane with a pore size of 0.65μm. After filtration, measure the transmittance. If the transmittance is less than 97%, re-filter the filter until the transmittance is greater than or equal to 97%;

[0033] (2) Pass into sulfur dioxide in above-mentioned honey solution, the sulfur dioxide feed rate is less than 20mg / L;

[0034] (3) Take French wine dry yeast and add it to 10% sucrose aqueous solution, activate it in a water bath at 37°C for 22 minutes;

[0035] (4) Control the temperature of the honey solution at 26°C, add activated French wine dry yeas...

Embodiment 3

[0037] A method for producing a royal jelly honey fermented beverage, comprising the following steps:

[0038] (1) Add honey to an appropriate amount of clear water, heat up to 30°C and stir to make the honey completely melt into a homogeneous solution, add water until the mass concentration of the honey solution is 10%, heat up to 60°C and keep it for 10 minutes, after cooling, use a pore size of Filter through 100μm gauze, and then filter with a filter membrane with a pore size of 0.65μm. After filtration, measure the transmittance. If the transmittance is less than 97%, re-filter the filter until the transmittance is greater than or equal to 97%;

[0039] (2) Pass into sulfur dioxide in above-mentioned honey solution, the sulfur dioxide feed rate is less than 20mg / L;

[0040] (3) Take French wine dry yeast and add it to 10% sucrose aqueous solution, activate it in a water bath at 35°C for 20 minutes;

[0041] (4) Control the temperature of the honey solution at 26°C, inser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com