A kind of DMAC waste liquid processing method that spandex contains acetic acid

A technology for waste liquid treatment and acetic acid, which is applied in the separation/purification of carboxylic acid compounds, separation/purification of carboxylic acid amides, organic chemistry, etc. Improve recovery rate, good economic and social benefits, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

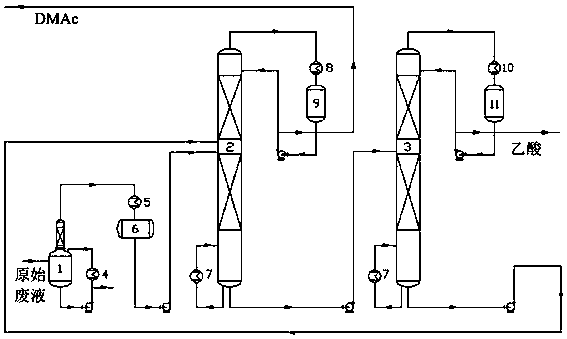

Embodiment 1

[0030] Take the waste liquid discharged by the spandex production enterprise as an example. The original waste liquid is sent to the pretreatment tower 1. The mass fractions of the components in the original waste liquid are 85% DMAc, 12% acetic acid, and 3% high polymer. It is 500Kg / h. The operating pressure of the pretreatment tower 1 is 0.02MPaA, the pressure drop of the whole tower is 0.002MPaA, the top temperature of the tower is 130°C, and the reflux ratio is 0.1. The tower top material is temporarily stored in the feed buffer tank 6 after the temperature is adjusted by the condenser A 5, and the material composition is 87% DMAc and 13% acetic acid. The bottom of the pretreatment tower 1 collects polymer-containing raffinate, a part of which is returned to the top of the pretreatment tower 1 as reflux after temperature adjustment by the heat exchanger 4, and a part is produced as the raffinate.

[0031] The material in the feed buffer tank 6 is pumped into the low-pressure...

Embodiment 2

[0035] Take the waste liquid discharged by the spandex production enterprise as an example. The original waste liquid is sent to the pretreatment tower 1. The mass fractions of the components in the original waste liquid are 94% DMAc, 4% acetic acid, 2% high polymer, and the feed amount It is 1000Kg / h. The operating pressure of the pretreatment tower 1 is 0.01 MPaA, the pressure drop of the whole tower is 0.002 MPaA, the temperature at the top of the tower is 125°C, and the reflux ratio is 0.1. The tower top material is temporarily stored in the feed buffer tank 6 after the temperature is adjusted by the condenser A 5, and the material composition is 95.5% DMAc and 4.5% acetic acid. The bottom of the pretreatment tower 1 collects polymer-containing raffinate, a part of which is returned to the top of the pretreatment tower 1 as reflux after temperature adjustment by the heat exchanger 4, and a part is produced as the raffinate.

[0036] The materials in the feed buffer tank 6 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com