Silica sol enhanced hollow safety glass and preparation method thereof

A technology of silica and safety glass, applied in chemical instruments and methods, glass/slag layered products, other household appliances, etc., can solve the problems of difficult to eliminate self-explosion, can not reduce the high cost of glass, aging and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: the present invention implements coating SiO to the single side of single-layer glass 2 For the sol, the glass substrate uses common soda-lime annealed glass, which is thin glass with a thickness of 2mm. Coatings were prepared by the sol-gel method. The sol uses tetraethyl orthosilicate as the main raw material, γ-glycidyl etheroxypropyl trimethoxysilane (KH560) as the coupling agent, water and alcohols (ethanol or isopropanol) as the solvent, and the water and alcohol in the solvent The proportion is 1:3 (weight ratio), mixed according to the ratio of main raw material 14%, coupling agent 12%, solvent 74% (by weight ratio), and adding 2% of the total mass of main raw material, coupling agent and solvent 0.1mol / L nitric acid, prepared as acidic SiO 2 Sol. On one side of the single-layer glass, use a wire bar coater to apply the sol by scraping, the wet film thickness is 100 μm, and after standing for leveling, heat-cure at 180°C for 1 hour to obtain a s...

Embodiment 2

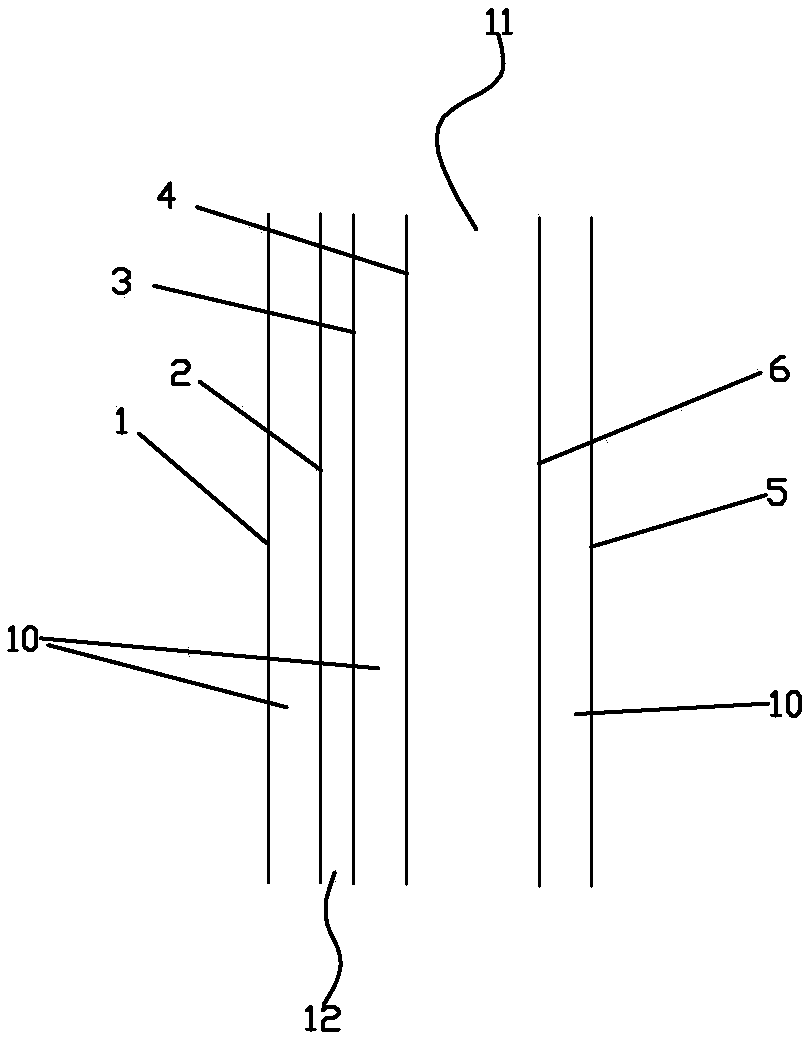

[0035] Embodiment 2: by (2mm semi-tempered glass)+1.52PVB+(2mm semi-tempered glass+1μmSiO 2 coating)+12mm hollow structure+(1μmSiO 2 Coating + 4mm semi-tempered glass), according to the combination of overlapping together to make such figure 1 Insulating safety glass shown, SiO 2 The coating is located on figure 1 The 4th and 6th sides of the same example, the other is the same as that of Example 1, the measured compressive strength> 6000Pa, reaching the wind compressive strength required by the building design code (the compressive strength of a 6mm single-layer glass sheet is not less than 5000Pa), meeting JC846- The requirements for Class A and Class B safety glass specified in the 2007 standard.

Embodiment 3

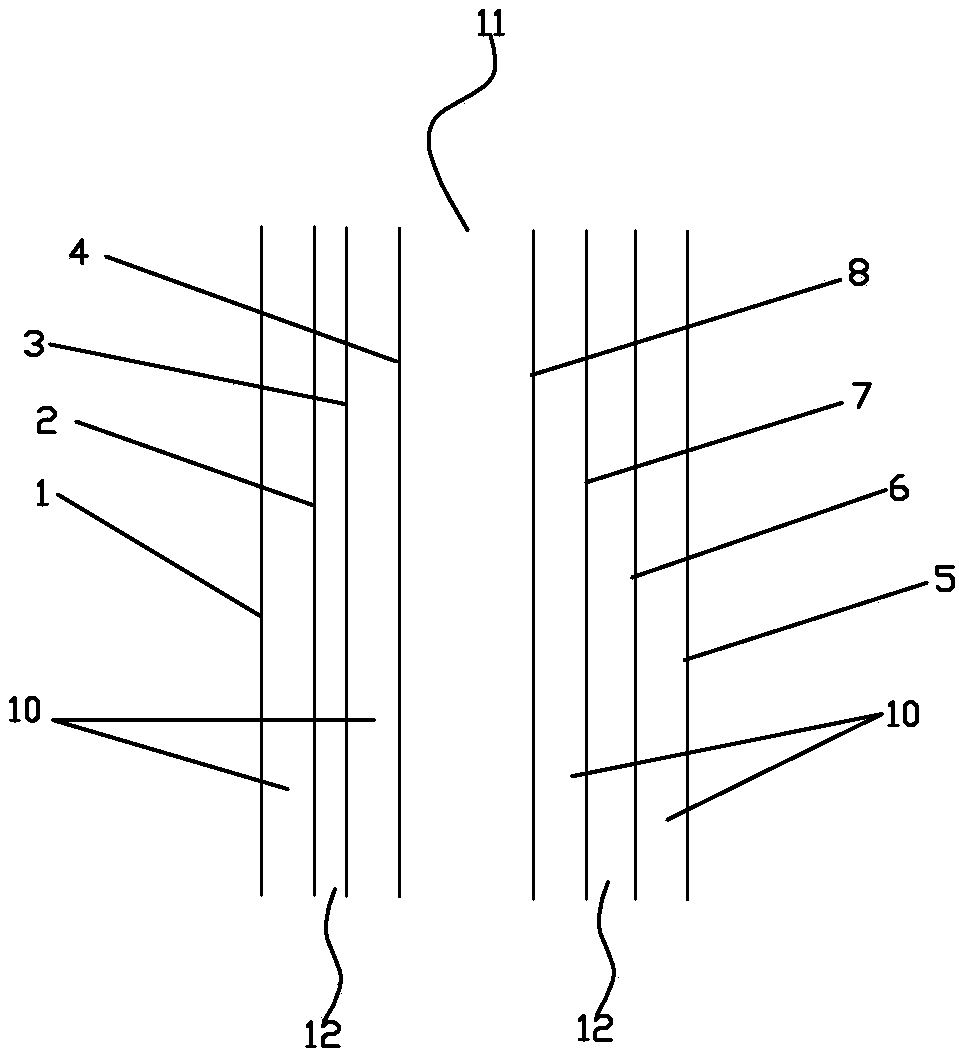

[0036] Embodiment 3: by (2mm semi-tempered glass)+1.52PVB+(2mm semi-tempered glass+15μmSiO 2 Coating) + 12mm hollow structure + (2mm semi-tempered glass) + 1.52PVB + (2mm semi-tempered glass), according to the combination of overlapping to make such figure 2 Insulating safety glass shown, SiO 2 The coating is located on figure 2 The fourth side is the same as that in Example 1, and the measured compressive strength is >6000Pa, which reaches the wind compressive strength required by the architectural design code (the compressive strength of a 6mm single-layer glass sheet is not less than 5000Pa), and meets the requirements of the JC846-2007 standard. The requirements for Class A and Class B safety glass are specified.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com