Near-zero emission tail water treatment method of wastewater in coal chemical industry

A technology for industrial wastewater and process methods, which is applied in the directions of oxidized water/sewage treatment, water/sewage treatment, biological water/sewage treatment, etc., to achieve the effects of environmental friendliness, high recycling rate, and burden reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

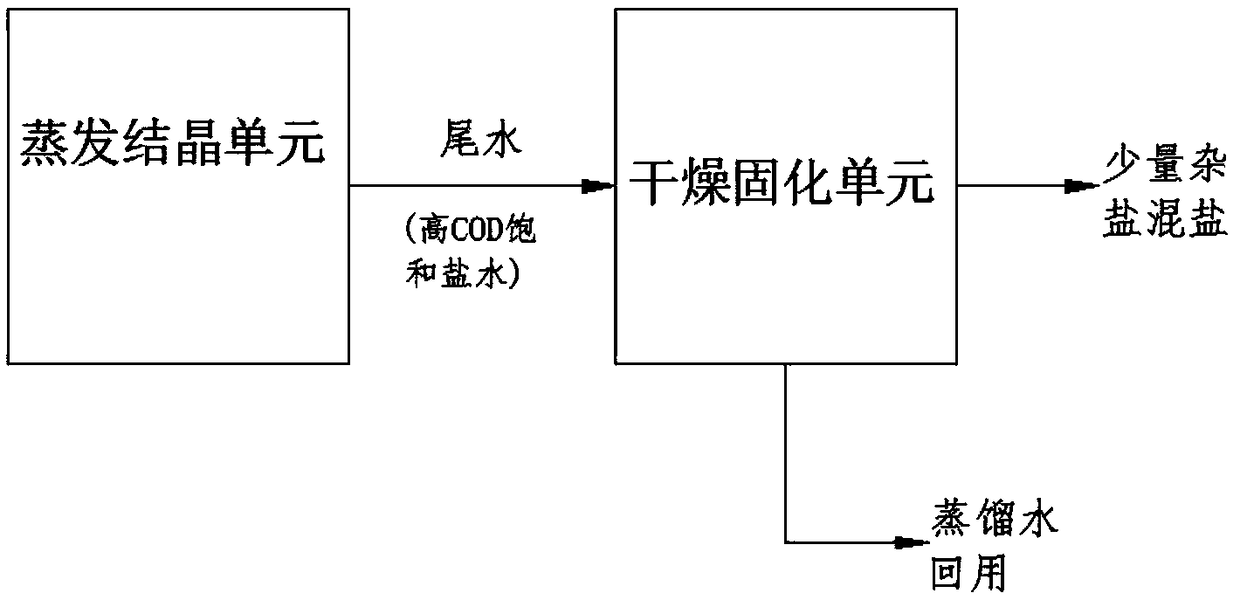

Embodiment 1

[0024] In order to make the process method and advantages of the present invention more clear, this embodiment combines the actual characteristics of coal chemical industry wastewater, and adopts the method of direct drying to treat the evaporation and crystallization tail water. Compared with the outsourced treatment of tail water, it reduces the total treatment cost, realizes the complete zero discharge of waste liquid, increases the reuse rate of distilled water, and saves water resources.

[0025] In the example, the high-salt and high-organic-matter wastewater mainly includes sodium chloride, sodium sulfate, etc., and the organic matter components are mainly long-chain refractory components. Examples use saturated or superheated steam as a heat source. The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0026] In the embodiment, the main process of waste water adopts nanofiltration to separate salts. The monova...

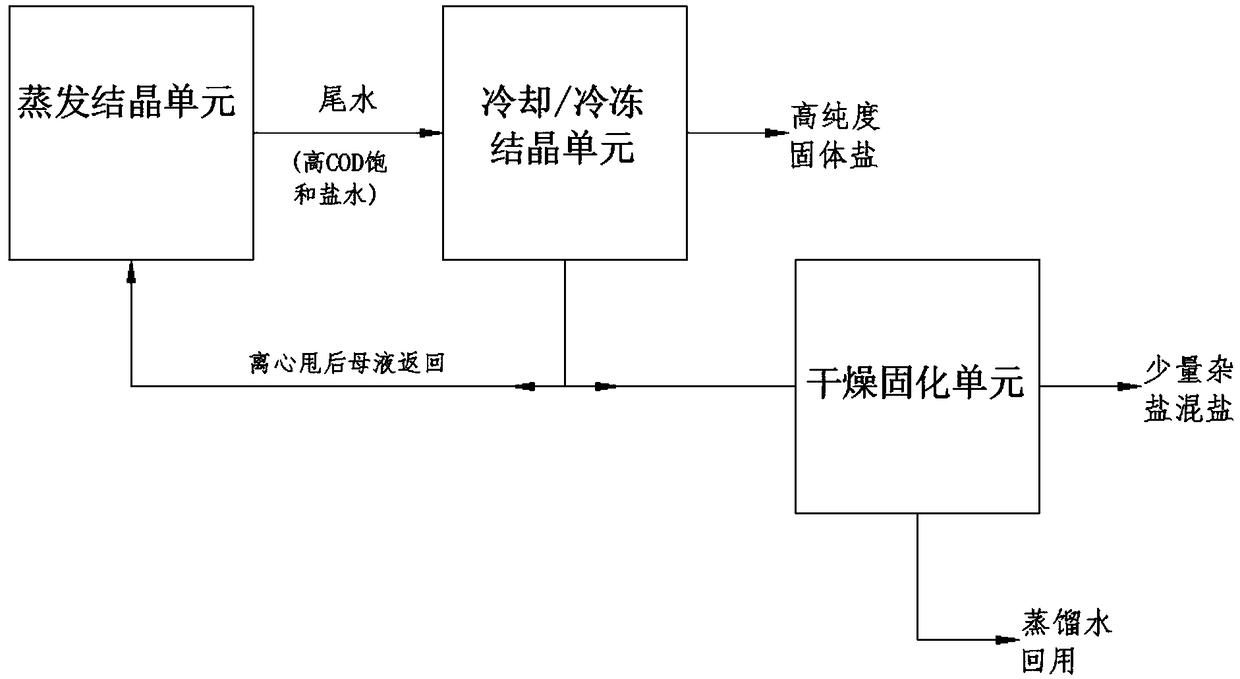

Embodiment 2

[0031] In order to make the process method and advantages of the present invention clearer, this embodiment combines the actual characteristics of coal chemical industry wastewater, and adopts the method of cooling crystallization to purify part of the auxiliary salt and then drying to treat the evaporation crystallization tail water. Compared with the outsourced treatment of tail water, it reduces the total treatment cost, realizes the complete zero discharge of waste liquid, increases the reuse rate of distilled water, saves water resources, and recovers some auxiliary salts.

[0032] In the embodiment, the high-salt and high-organic waste water mainly contains sodium chloride, sodium sulfate, etc., and contains a small amount of sodium nitrate. The organic components are mainly long-chain refractory components. Examples use saturated or superheated steam as a heat source. The present invention will be described in further detail below in conjunction with the accompanying dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com