Vertical descending delivery frame device of conveying system

A conveying system and shelf technology, which is applied in the field of conveying systems, can solve problems such as waste of indoor space, difficult use of space, inconvenient setting of horizontal lines, etc., and achieve the effects of good stability, improved structure compactness, and convenient positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

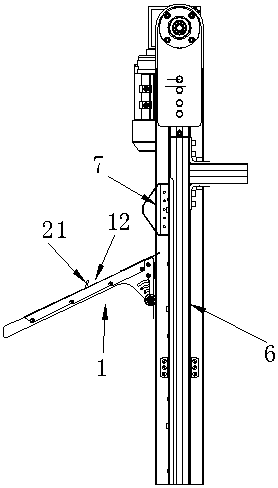

[0020] With reference to the accompanying drawings, the conveying system vertically descends the delivery rack device, which includes a support body arranged vertically. The support body can be the column 6 shown in the figure, or it can be a wall. The drive chain is rotatably arranged on the outer periphery of the support body, the drive chain is connected with the drive motor, the inner ends of several hangers 1 are connected to the drive chain, driven by the drive motor, the hanger 1 reciprocates in the vertical direction .

[0021] This vertically descending delivery rack device is used to transport the racks from the upper side to the guide rail of the lower horizontal line. The hanger 1 accepts the hooking of the racks from the upper side. Driven by the driving chain, the hanger 1 with the racks is hooked. Move down vertically. The structure of the lower horizontal line includes a needle drive mechanism and a guide rail arranged in parallel, and an introduction rod is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com